Structural improvement for cup container

a cup container and structure technology, applied in packaging, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of complex manufacturing procedure and drawback of foregoing conventional structure, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]Other features and advantages of the present invention will become apparent from the following description of the invention which refers to the accompanying drawings.

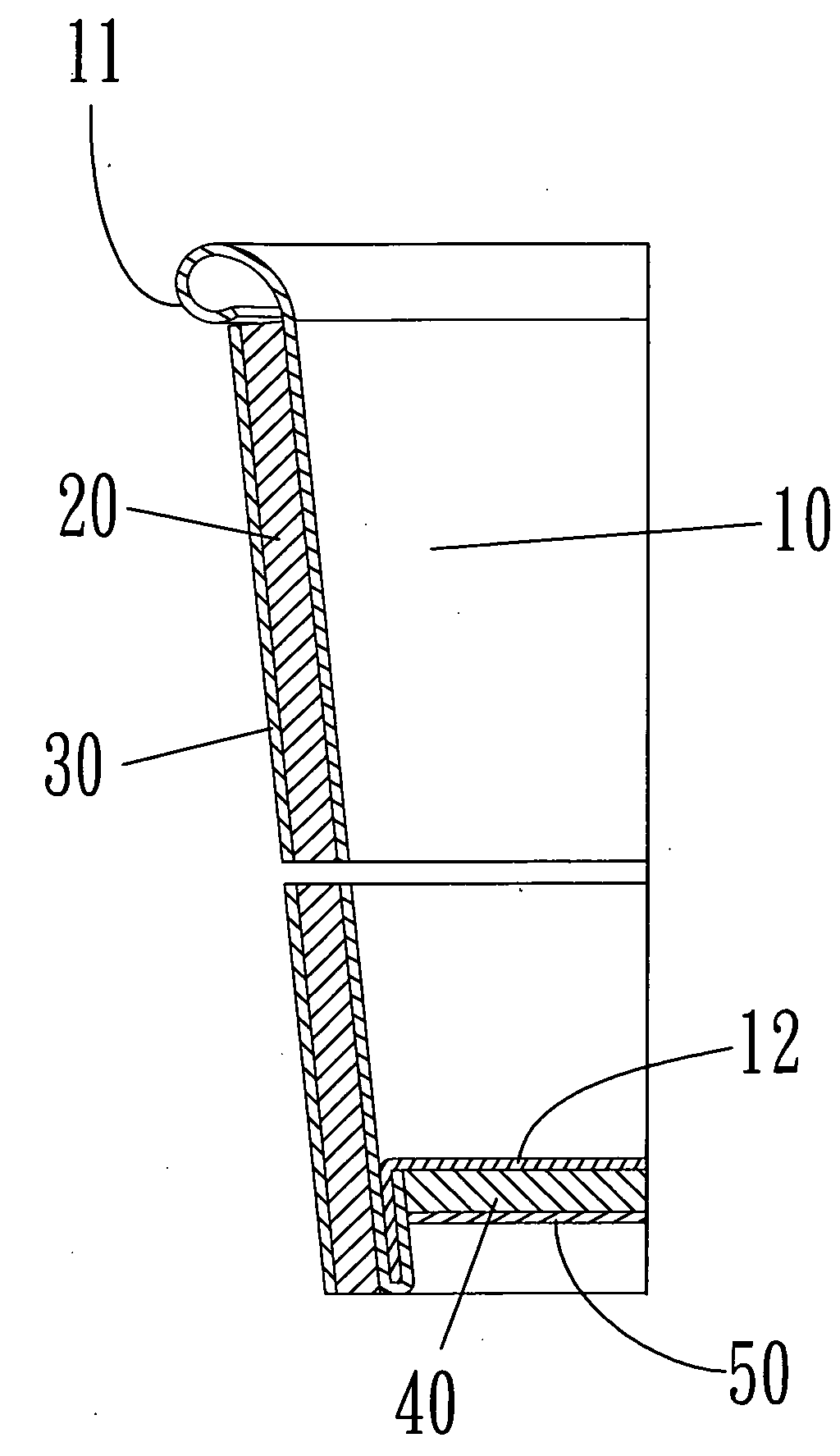

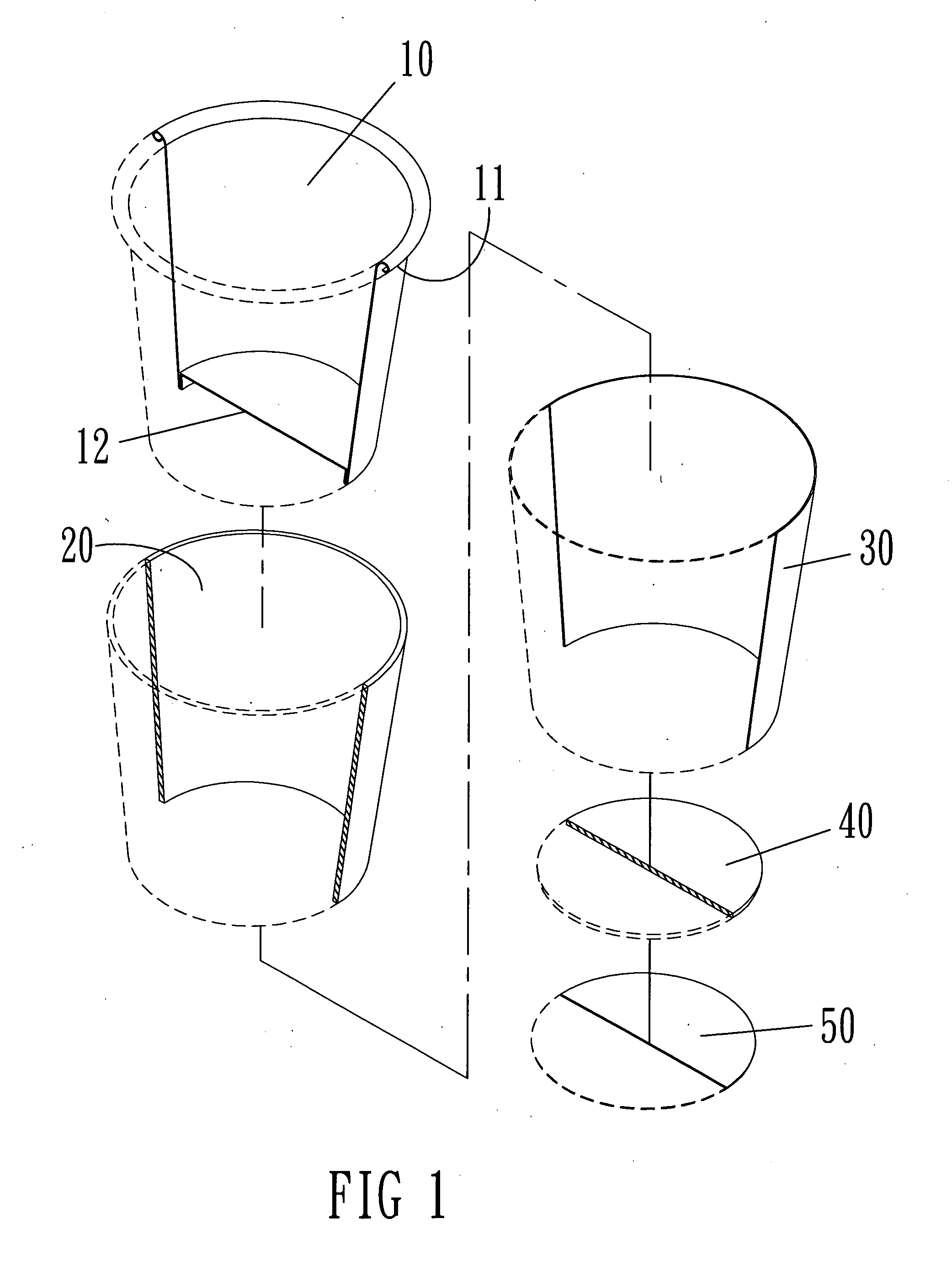

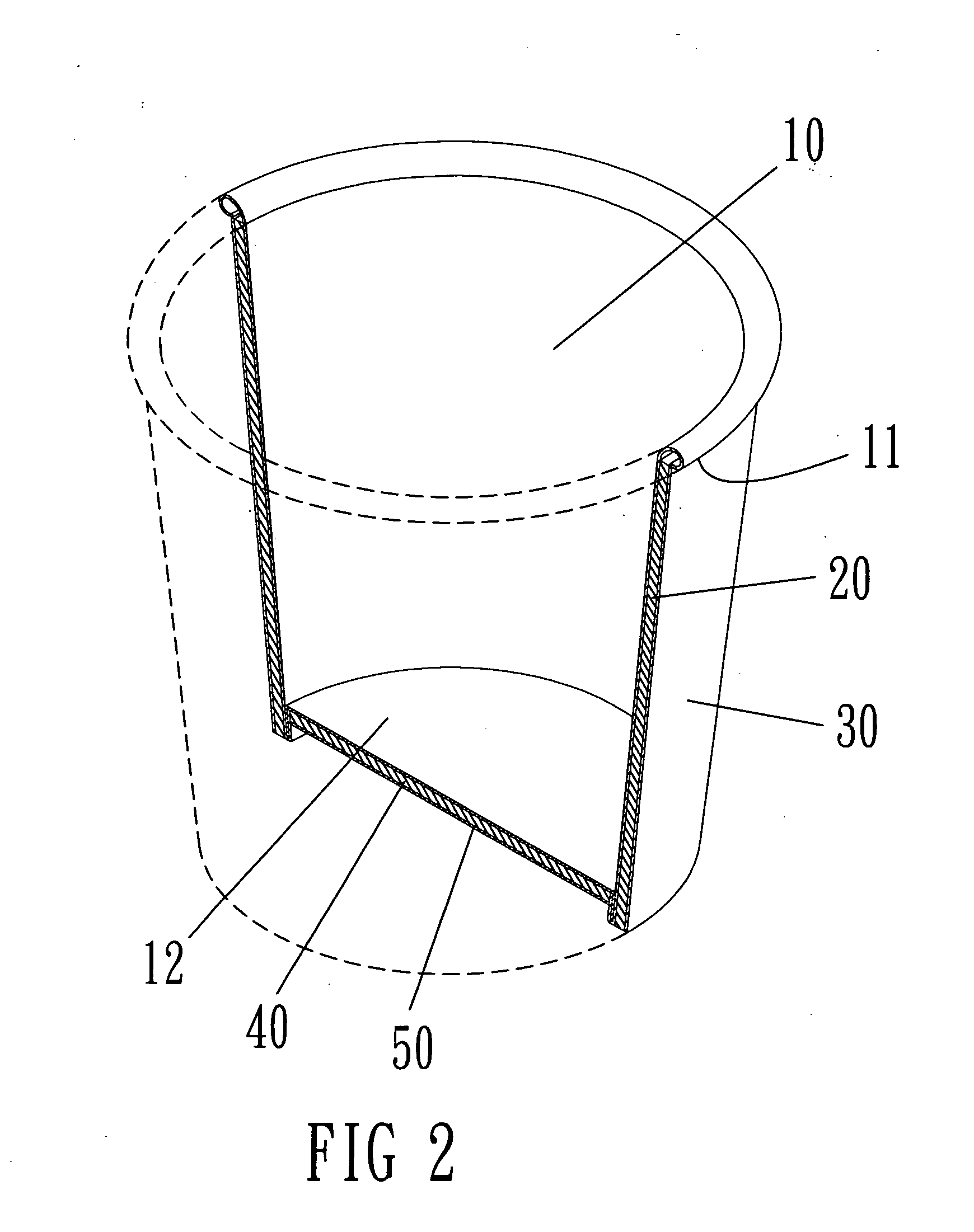

[0015]First, please refer to FIG. 1 to FIG. 3, a structural improvement for a cup container of the present invention is shown. The container is composed of an internal layer paper cup 10, a foam layer 20 and an external layer paper cup 30. The internal layer paper cup 10 is a conventional paper cup. An internal surface of the internal layer paper cup 10 is coated with a waterproof layer. An upper of the internal layer paper cup 10 faces toward outside firstly, and then is inwardly folded, thereby becoming a protruding lip 11. An internal paper cup bottom 12 is bonded to a bottom of the cup container. The foregoing waterproof layer is a necessary structure as a standard. Since the waterproof layer is a thin-film layer, it is merely written in the specification without specifically showing it in the figure. The stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com