Hollow heat insulation paper cup and paper cup molding machine for manufacturing same

A technology of forming machine and thermal insulation paper, which is applied in the direction of carton/carton manufacturing machinery, paper/cardboard containers, drinking vessels, etc., can solve the problems of complex structure, poor heat insulation effect, high cost, etc., and achieve cost reduction and prominent Substantial features, the effect of improving the heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

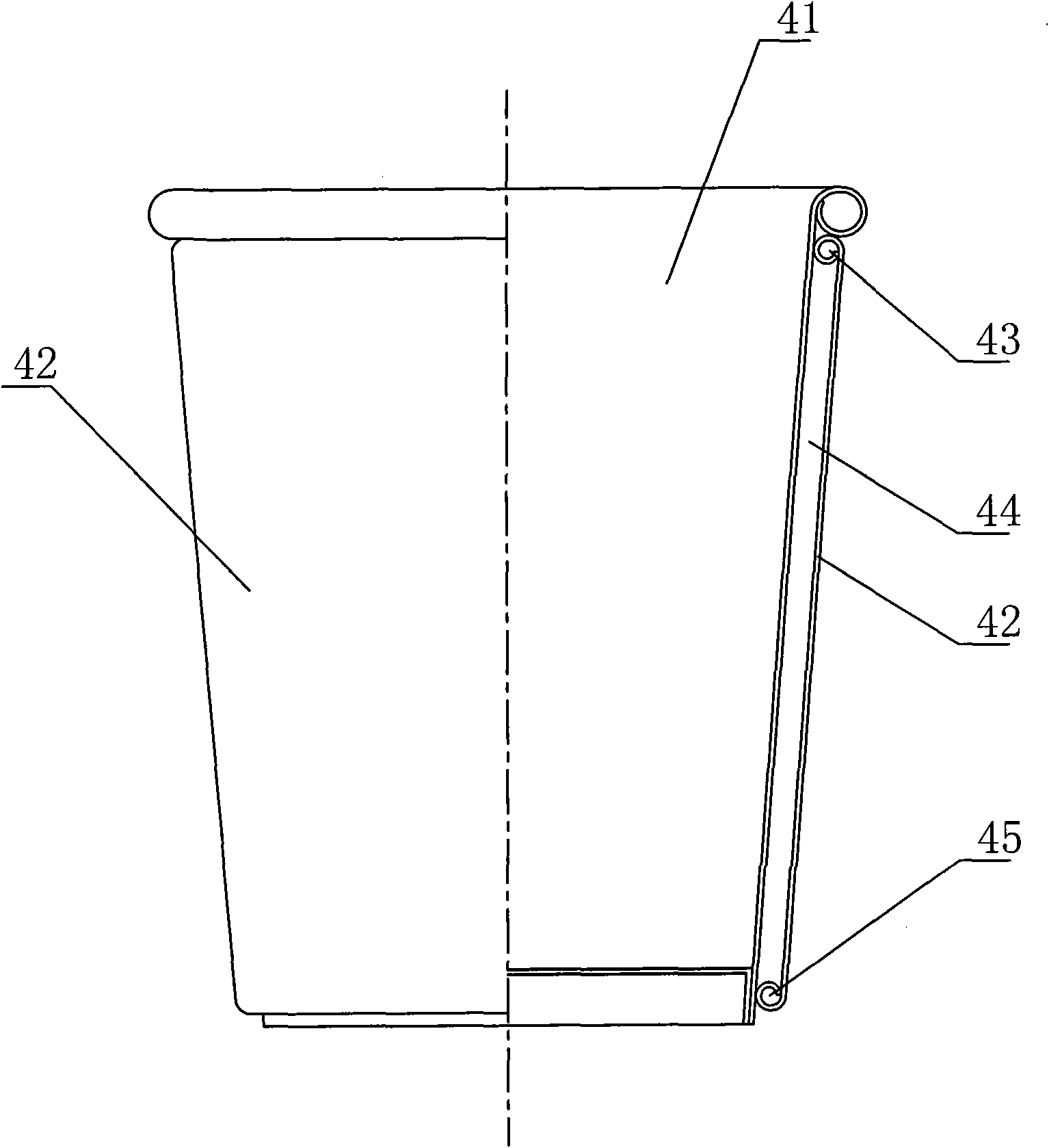

[0012] Refer to attached figure 1 , this kind of hollow heat-insulating paper cup is composed of an inner cup 41 and a jacket 42 that are nested together. The upper mouth of the jacket 42 is rolled inward to form a circle to form an inner roll mouth 43, and the lower mouth of the jacket 42 is rolled inward. Form the inner rolling bottom 45 in a circle, and of course also fold the bottom inwardly to form the inner rolling bottom. After the outer cover 42 with the inner rolling bottom 45 and the inner rolling mouth 43 is combined with the inner cup 41, the outer cover 42 and the inner cup 41 cup wall There is a suitable hollow gap 44 from top to bottom, so the heat insulation effect of this kind of paper cup is very good.

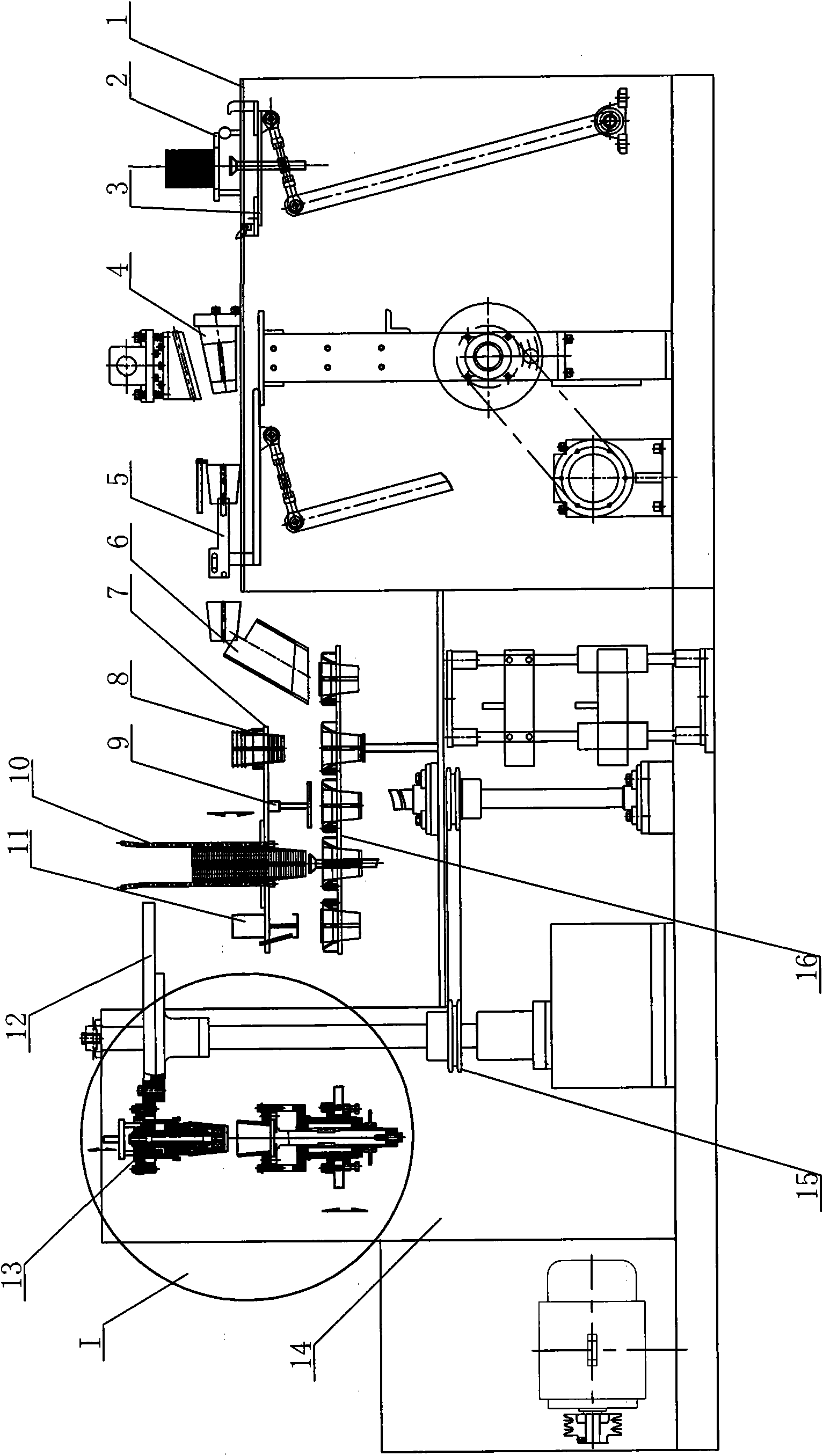

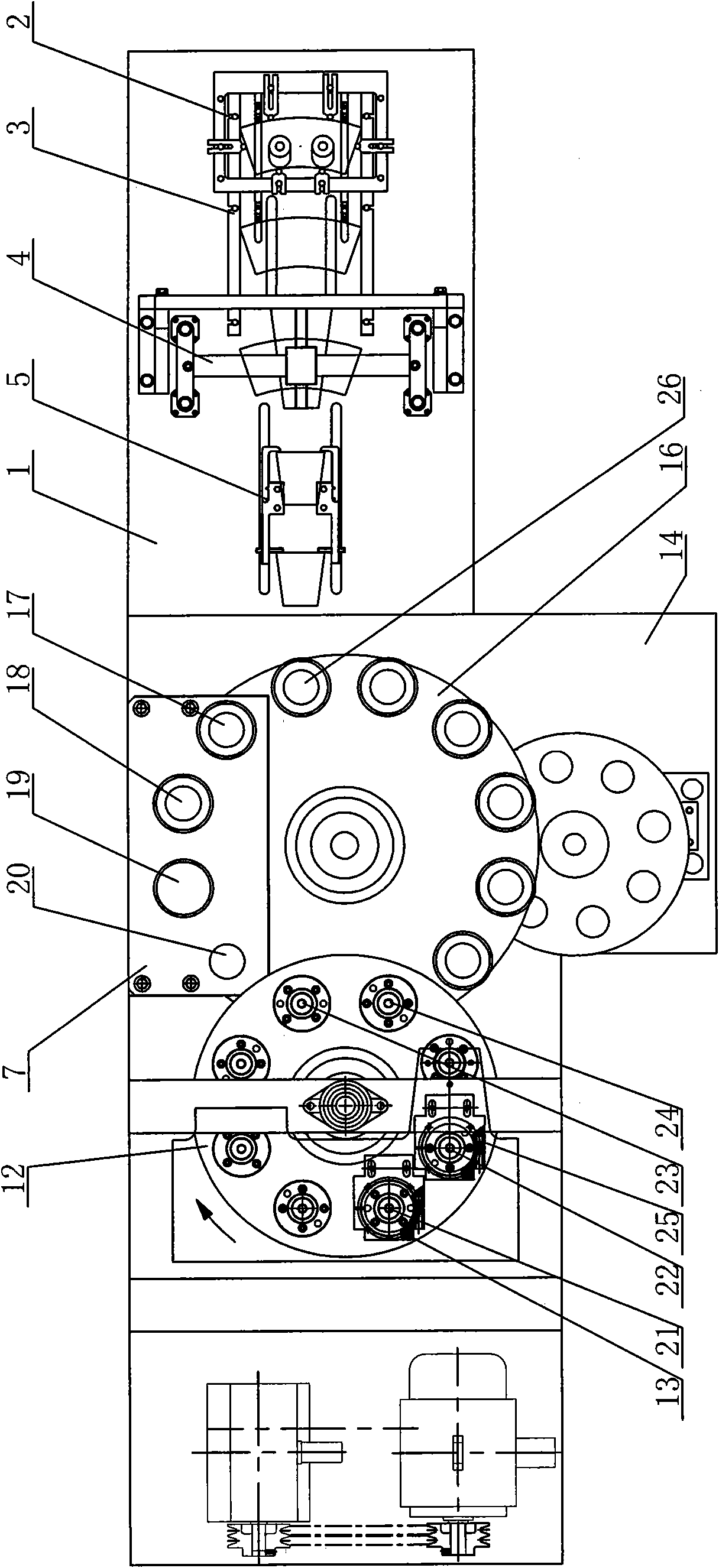

[0013] Refer to attached figure 2 , 3 4. This kind of paper cup forming machine includes front and rear bases 1 and 14, and the front base 1 is equipped with a suction jacket paper sheet mechanism 2, a paper feeding mechanism 3, a jacket barrel bonding mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com