Measuring instrument for paper cup

A measuring instrument and paper cup technology, applied in the field of paper cup measuring instruments, can solve the problems of inaccurate measurement results, deformation of paper products, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings of the description.

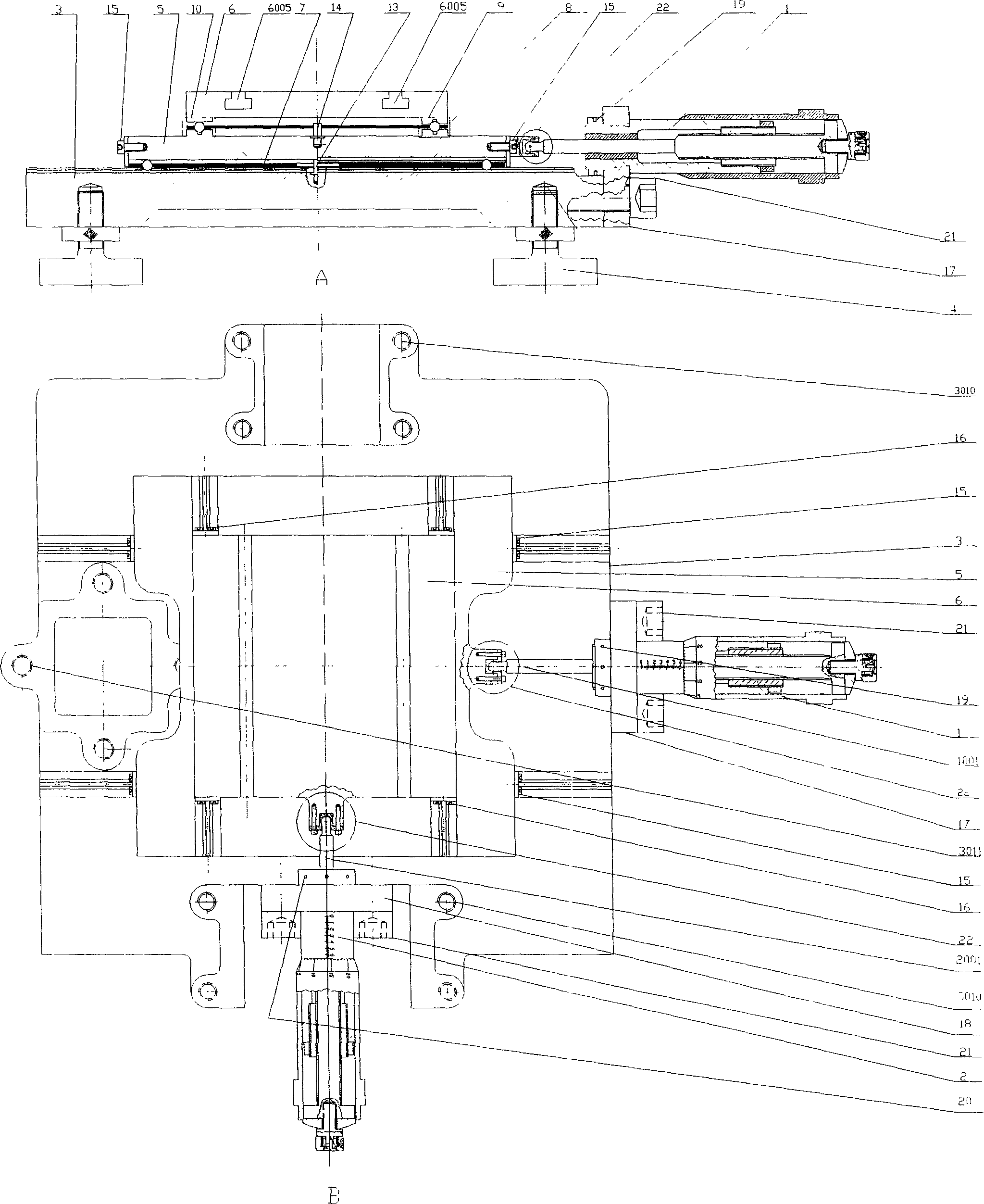

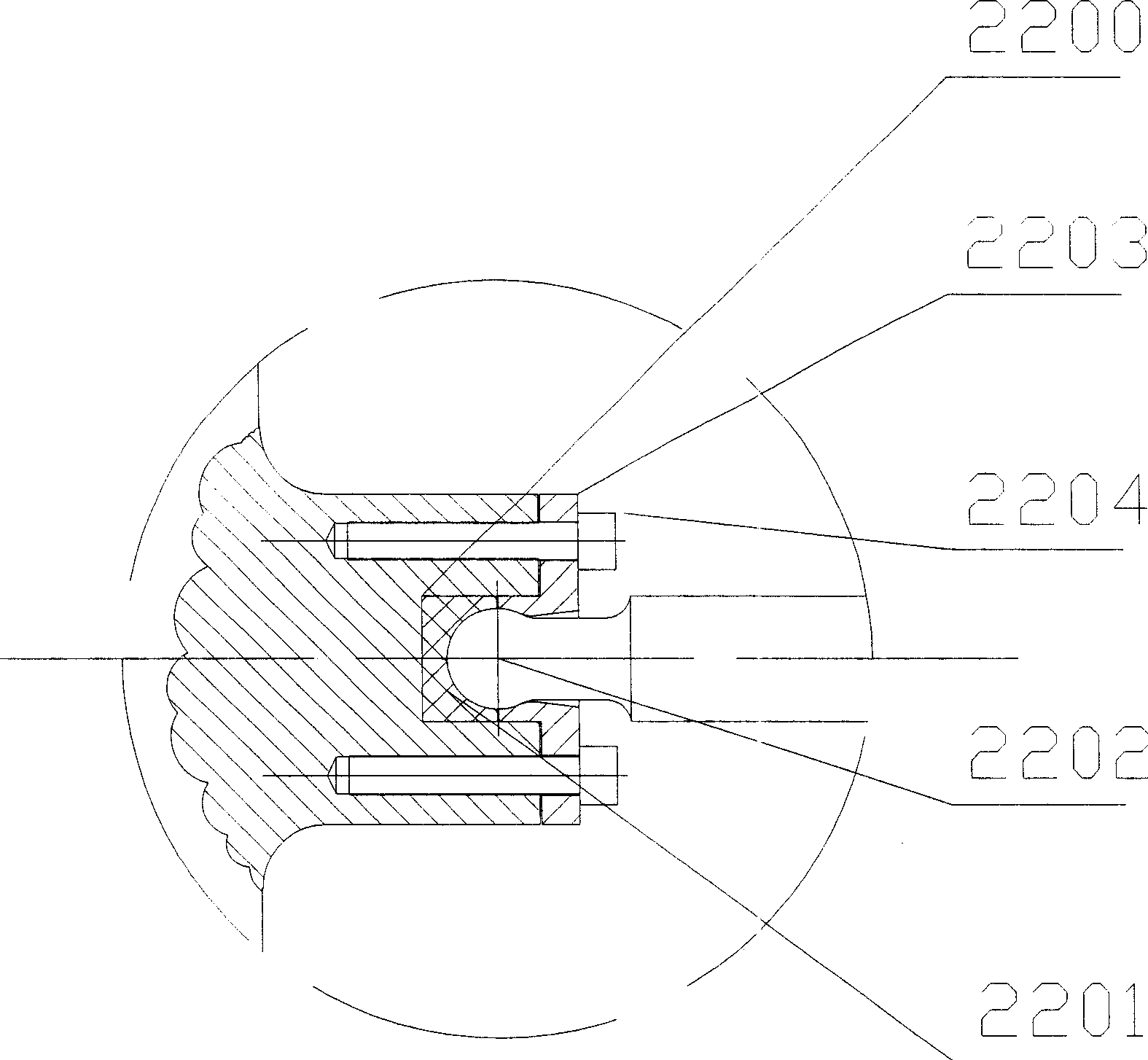

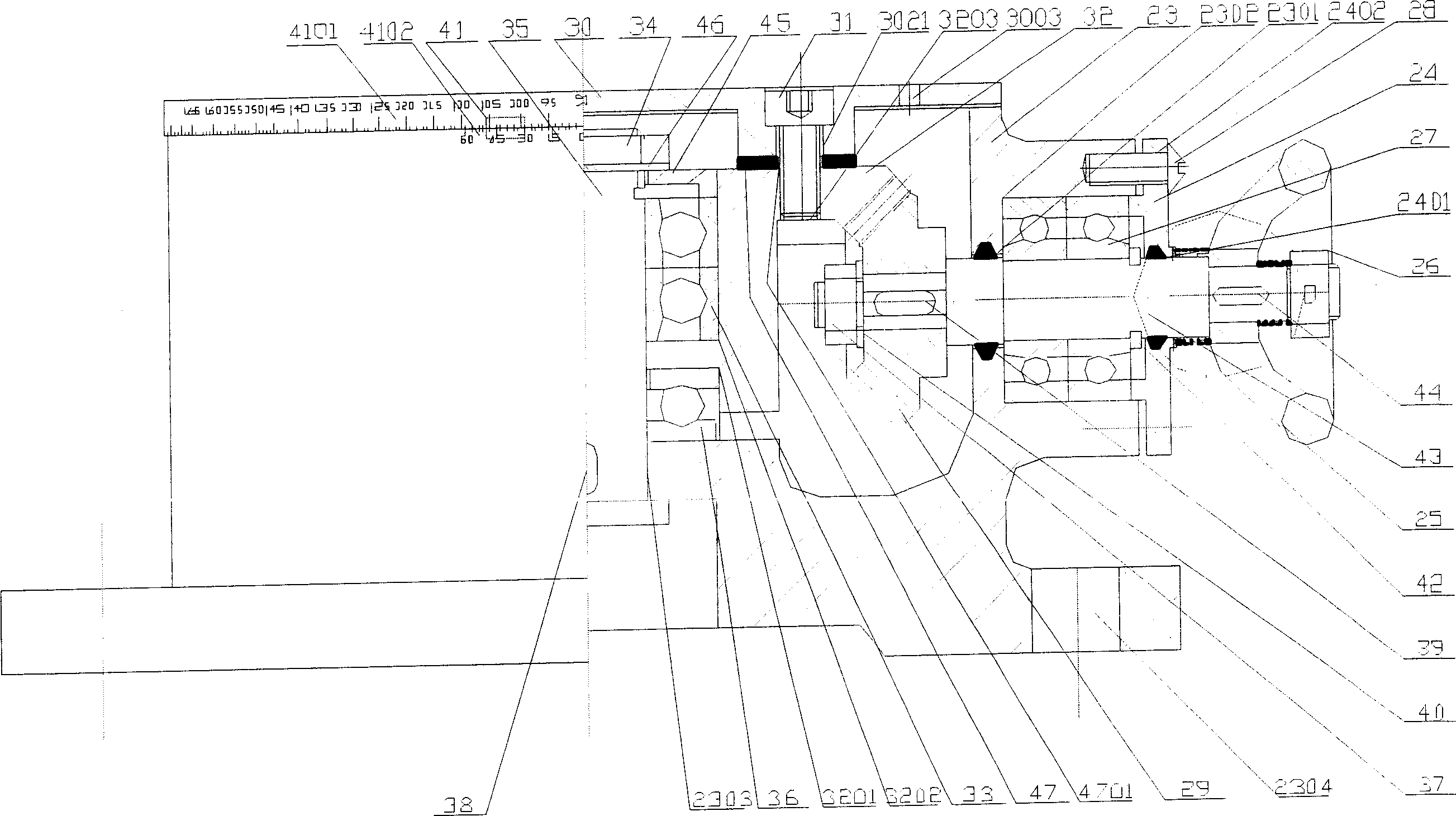

[0045] The technical scheme of the paper cup measuring instrument of the present invention includes two major parts: geometric centering aiming and servo drive technical scheme, position detection and signal acquisition and processing technical scheme, etc., wherein the geometric centering aiming and servo driving technical scheme consists of X-Y workbench device technical scheme, It is composed of the technical scheme of the rotary table device, the technical scheme of the X-Y elastic micro-motion worktable device, and the A and B technical schemes of the Z-direction lifting table device.

[0046] The technical scheme of the X-Y workbench device is: see figure 1 A.figure 1 B. figure 2 , Figure 13 , Figure 14 As shown, it includes X-direction differential fine-tuning drive mechanism 1, Y-direction differential fine-adjustment drive me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com