Corrugated insulated paper cup and paper cup forming machine preparing same

A technology for forming machines and paper cups, which is applied in the directions of carton/carton manufacturing machinery, paper/cardboard containers, drinking utensils, etc. Good thermal insulation effect, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

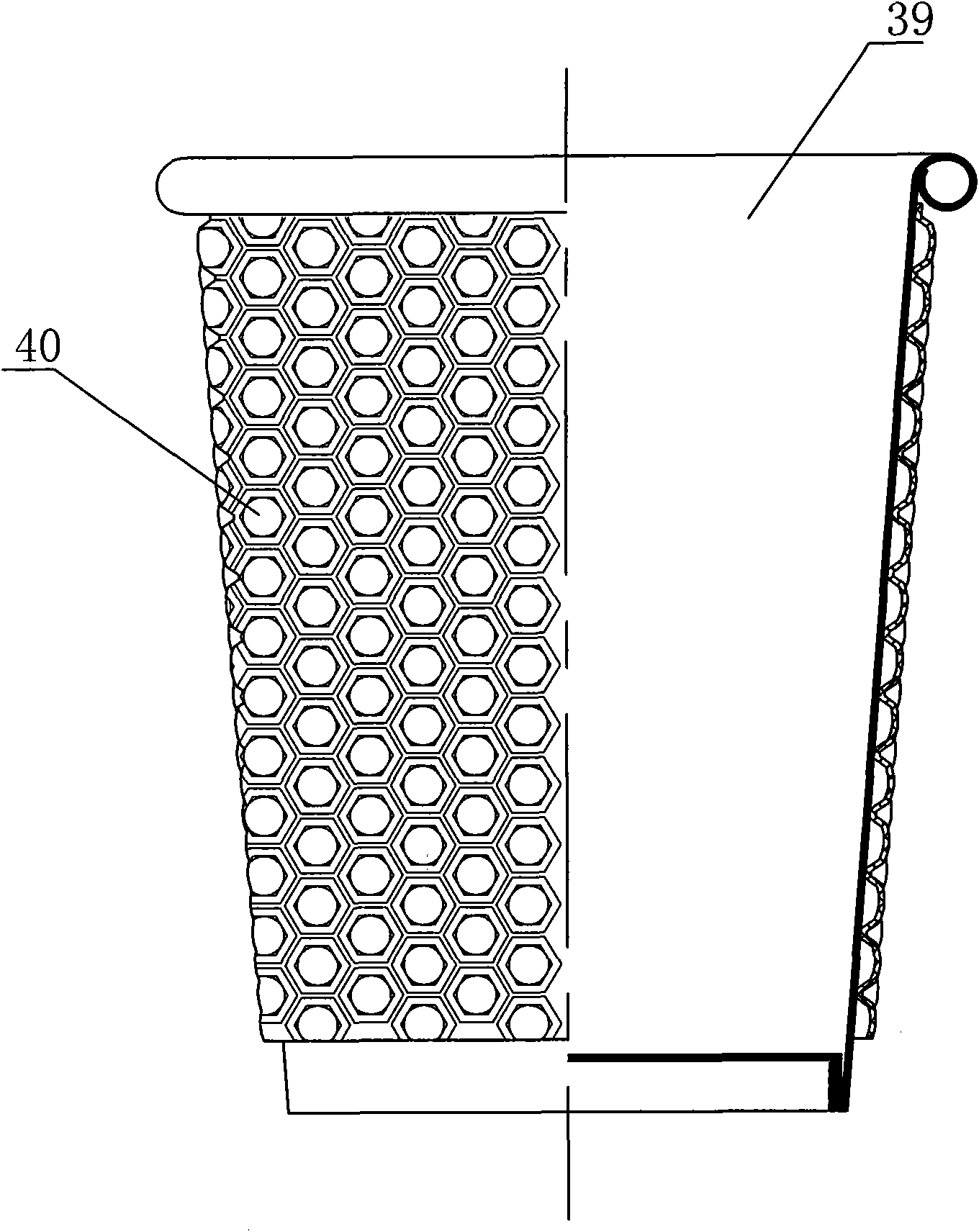

[0013] Refer to attached figure 1 , this kind of corrugated heat-insulating paper cup is made up of an inner cup 39 and a jacket 40 that are nested together. The inner cup 39 is a common disposable single-layer paper cup. The surface of the sheet is pressed with corrugated lines.

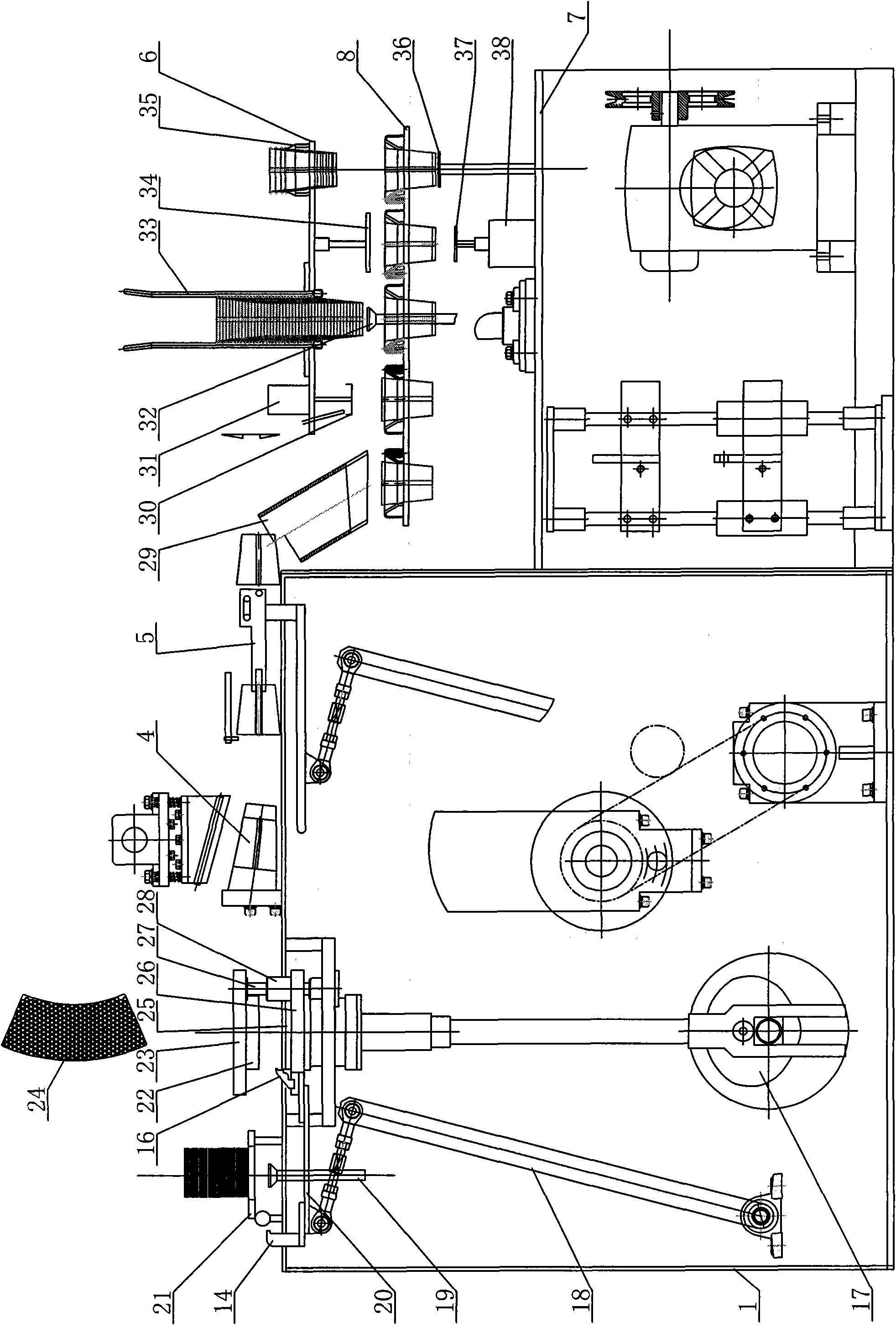

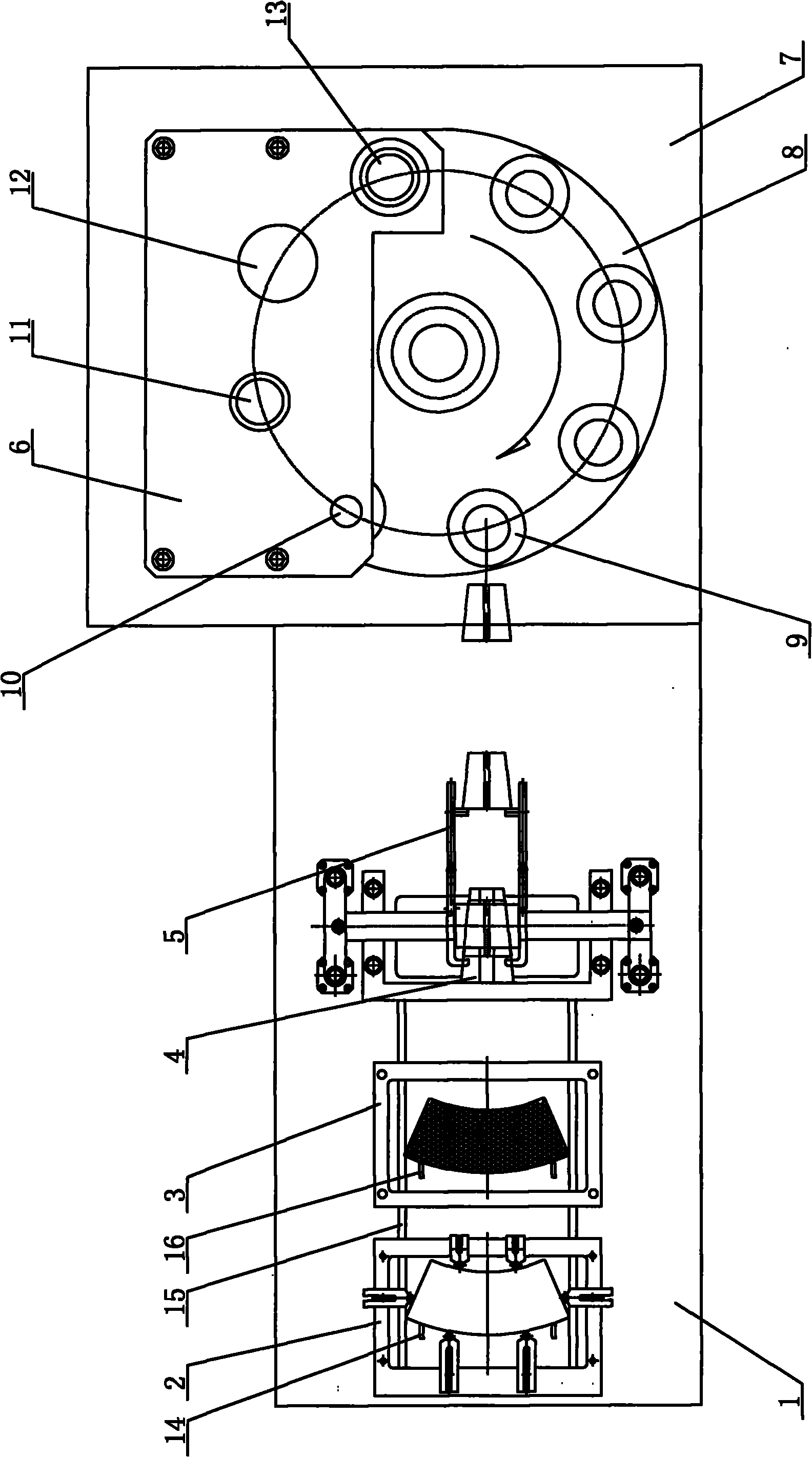

[0014] Refer to attached figure 2 , 3 , this kind of paper cup forming machine includes front and rear machine bases 1 and 7, and the front machine base 1 is equipped with a suction jacket paper mechanism 2, a paper feeding mechanism, a jacket paper creasing mold 3, and a jacket barrel bonding mechanism 4 And hook bucket mechanism 5, described overcoat paper sheet indentation mold 3 is located between suction overcoat paper sheet mechanism 2 and overcoat into bucket bonding mechanism 4, comprises upper and lower die frame 23,26 and the upper die that is installed in upper and lower die frame 22 and the lower mold 25, the upper and lower mold bases are slidingly connected by guide sleeves 28 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com