Frequency-adjustable transverse field excitation film bulk acoustic resonator and preparation method thereof

A thin-film bulk acoustic wave and transverse field technology, which is applied in the field of microelectronics, can solve the problems of increasing the difficulty of making filters, and achieve the effects of increasing acoustic wave transmission loss, easy manufacturing, and reducing device volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

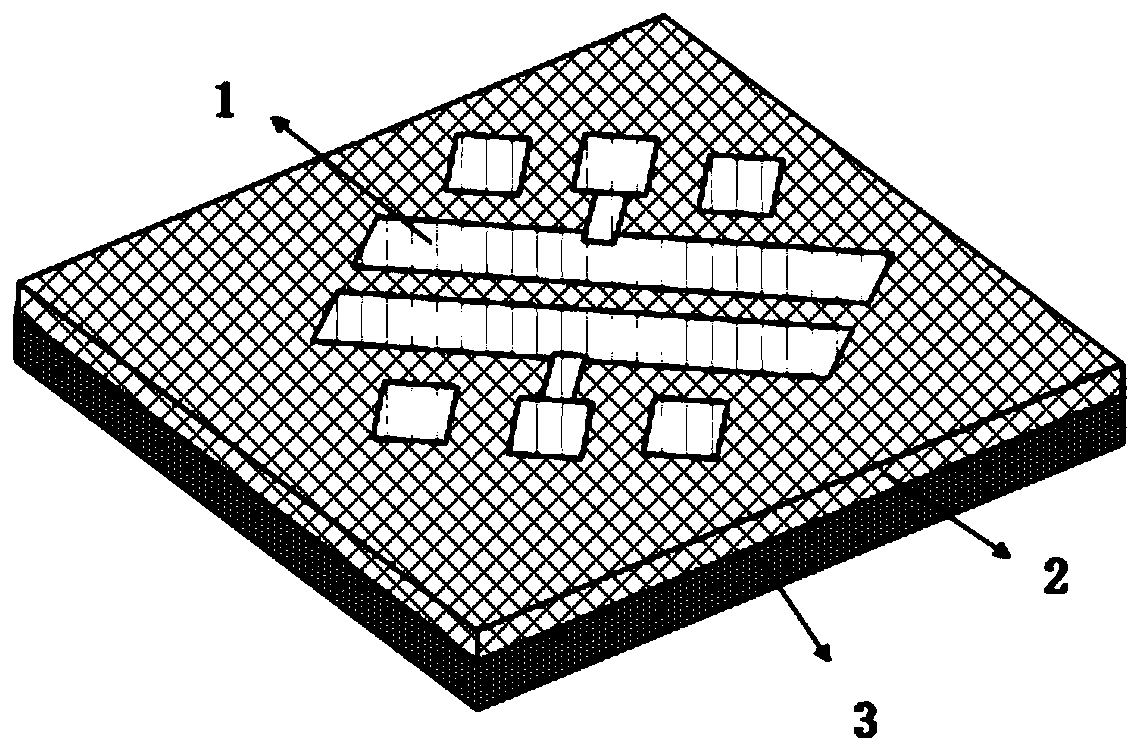

[0040] figure 1 It is a three-dimensional structure diagram of the transverse field excited film bulk acoustic resonator simulated in the present invention, including electrode aluminum 1, piezoelectric substrate 2, and temperature compensation layer 3 placed sequentially from top to bottom. In this embodiment, the piezoelectric substrate The Y-42 cut single crystal lithium tantalate material is selected, and the temperature compensation layer is made of silicon dioxide.

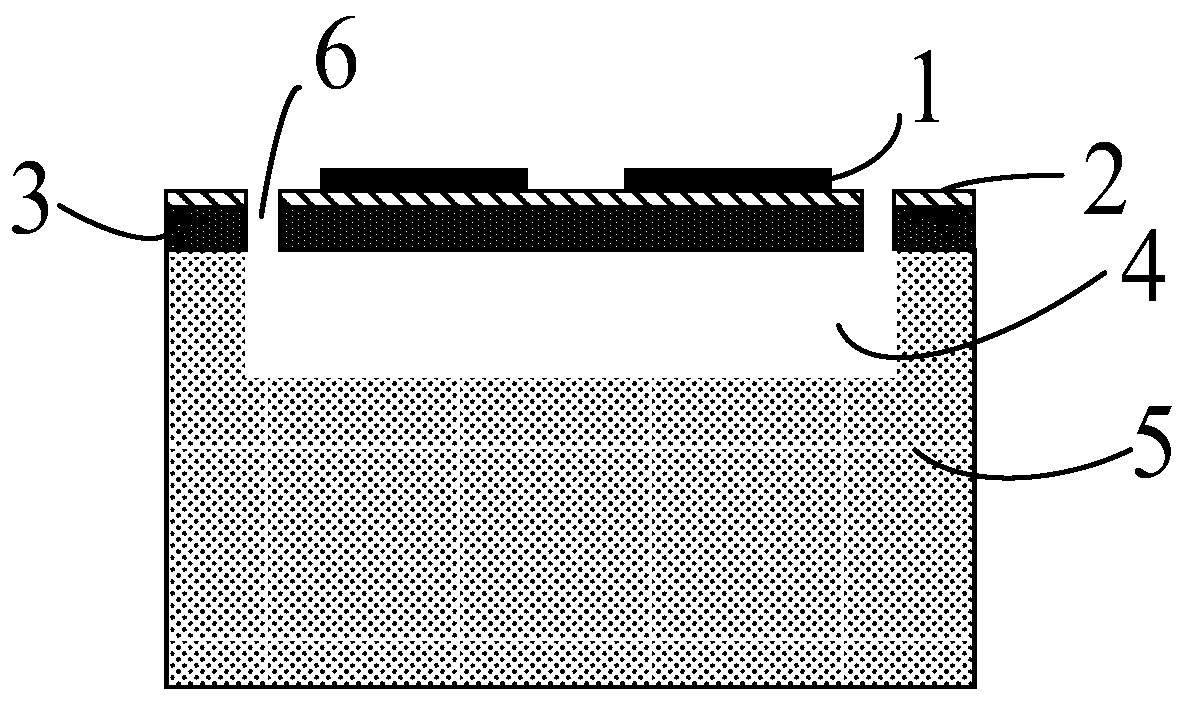

[0041] figure 2 The cross-sectional view of the lateral field-excited thin-film bulk acoustic resonator is shown, the temperature compensation layer is arranged on the substrate, and the substrate 5 is provided with a cavity 4, which is symmetrical about the longitudinal center line of the substrate and extends downward from the upper edge. The temperature compensation layer is between the piezoelectric substrate and the substrate, the electrode aluminum is located on the same surface of the piezoelectric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com