Starch-based water reducing agent and production process thereof

A high-efficiency water reducer, starch-based technology, applied in the field of starch-based high-efficiency water reducer, can solve the problems of retardation and water reduction effect, many organic harmful substances, unfavorable environmental protection, etc., to achieve retardation and water reduction effect Excellent, lower production costs, and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

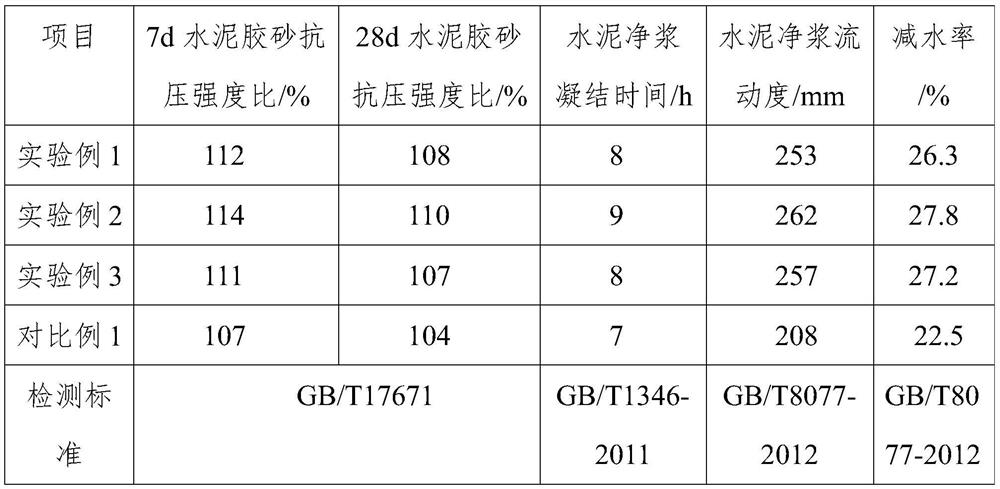

Examples

Embodiment 1

[0026] A starch-based high-efficiency water reducer, made of the following raw materials in parts by weight: 50 parts of corn starch, 4 parts of ammonium persulfate, 5 parts of ethylene oxide, 20 parts of sodium methacrylate, 4.5 parts of ammonium cerium nitrate , 2.5 parts of dihydroxysuccinic acid, appropriate amount of distilled water and absolute ethanol.

[0027] A production process of starch-based high-efficiency water reducer, comprising the following steps:

[0028] S1. Take an appropriate amount of starch sample, mix it with an appropriate amount of distilled water to form an appropriate concentration of starch milk; use an appropriate amount of sodium hydroxide solution to adjust its pH to 8.5, then add an appropriate amount of oxidizing reagent, and in 75 Under the condition of ℃, oxidize the starch milk for 4 hours, and the obtained product is recorded as the mixed component;

[0029] S2. Add an appropriate amount of hydrochloric acid solution to the mixed compon...

Embodiment 2

[0037] A starch-based high-efficiency water reducer, made of the following raw materials in parts by weight: 70 parts of potato starch, 5 parts of hydrogen peroxide, 8 parts of propylene oxide, 35 parts of sodium methacrylate, 6 parts of ammonium persulfate, 3.2 parts Dihydroxysuccinic acid, appropriate amount of distilled water and absolute ethanol.

[0038] A production process of starch-based high-efficiency water reducer, comprising the following steps:

[0039] S1. Weigh an appropriate amount of starch sample, mix it with an appropriate amount of distilled water to form an appropriate concentration of starch milk; adjust its pH to 9.2 with an appropriate amount of sodium hydroxide solution, then add an appropriate amount of oxidizing reagent, and in 80 Under the condition of ℃, oxidize the starch milk for 5 hours, and the obtained product is recorded as the mixed component;

[0040] S2. Add an appropriate amount of hydrochloric acid solution to the mixed components obtai...

Embodiment 3

[0048] A starch-based high-efficiency water reducer, made of the following raw materials in parts by weight: 80 parts of tapioca starch, 8 parts of potassium permanganate, 12 parts of butylene oxide, 45 parts of sodium methacrylate, 7.0 parts of persulfate Potassium, 4.0 parts of dihydroxysuccinic acid, appropriate amount of distilled water and absolute ethanol.

[0049] A production process of starch-based high-efficiency water reducer, comprising the following steps:

[0050] S1. Take an appropriate amount of starch sample, mix it with an appropriate amount of distilled water to form an appropriate concentration of starch milk; use an appropriate amount of sodium hydroxide solution to adjust its pH to 9.6, then add an appropriate amount of oxidizing reagent, and in 85 Under the condition of ℃, oxidize the starch milk for 6 hours, and the result is recorded as the mixed component;

[0051] S2. Add an appropriate amount of hydrochloric acid solution to the mixed components ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com