Carbide slag composite calcium-based desulfurizer based on biomass conditioning and preparation method thereof

A composite calcium-based, calcium carbide slag technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of industrialization difficulties, high costs, and high processing costs, and achieve improved diffusion capabilities, low production costs, and preparation short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]Composite desulfurizer ratio: electric gravel 70g, wheat straw 30g.

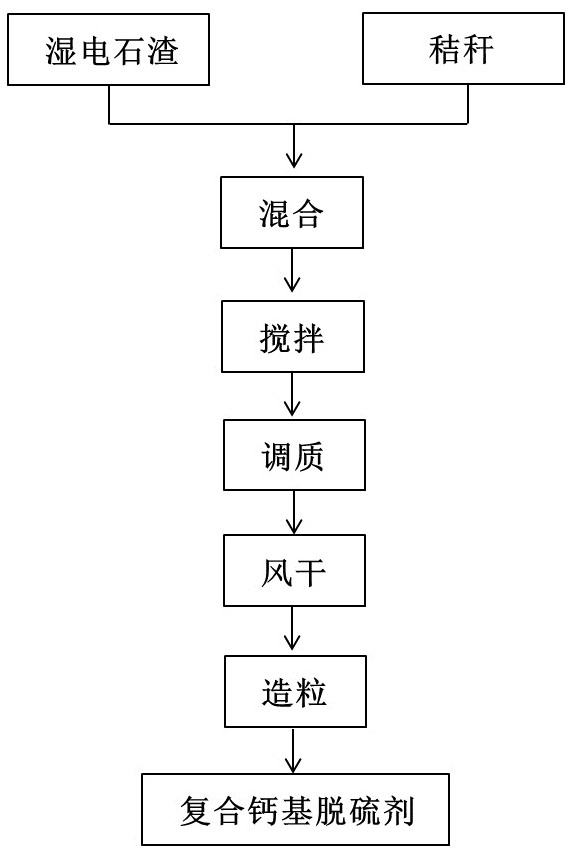

[0031]Method for preparing biomass-containing mesenchymal gravel composite calcium-based desulfurizers, including the following steps:

[0032]S1, the straw crushing with a raw material having a length of about 2 cm, mixing 30 g of wheat straw and 70 g of wet electric gravel, stirring rapidly for 30 min;

[0033]S2, combined S1 straw - electric gravel mixture in 20oC is placed for 6 days to adjust;

[0034]S3, the straw-iron stove mixture in S2 is naturally air-dried to water into 8% to prepare straw-electric gravel solids;

[0035]S4, a straw-tone solid of S3 is granulated under 8 mPa pressure, and a composite calcium-based deanger having a particle size of 2 cm is obtained.

[0036]Place 10 prepared composite calcium-based desulfurizers in 850oIn the tube furnace of C, enter the simulated flue gas, and the smoke CO2, O2SO2The volume fraction is 15%, 3%, 0.3%, respectively, with N2In order to balance the gas, after 8 min, th...

Embodiment 2

[0038]Composite desulfurization agent ratio: 40g of electric grades, 40g of corn stover.

[0039]Method for preparing biomass-containing mesenchymal gravel composite calcium-based desulfurizers, including the following steps:

[0040]S1, the straw crushing with a raw material having a length of about 2 cm, mixing 40g of corn stover and 60g wet electric gravel, stirring rapidly for 30 min;

[0041]S2, combined S1 straw - electric gravel mixture in 25oC plas for 5 days to adjust;

[0042]S3, the straw-iron gravel mixture in S2 is naturally air-dried to water into 5% to produce straw-electric gravel solid;

[0043]S4, a straw-monuctable solid of S3 is granulated under 10 MPa pressure, and a composite calcium-based deanger having a particle size of 2 cm is produced.

[0044]Place 10 prepared composite calcium-based desulfurizers in 850oIn the tube furnace of C, enter the simulated flue gas, and the smoke CO2, O2SO2The volume fraction is 15%, 3%, 0.3%, respectively, with N2In order to balance the gas, aft...

Embodiment 3

[0046]Composite desulfurization agent ratio: 40g of electric grades, 40g of corn stover.

[0047]Method for preparing biomass-containing mesenchymal gravel composite calcium-based desulfurizers, including the following steps:

[0048]S1, the straw crushing with a raw material having a length of about 2 cm, mixing 60g of corn stover and 40g wet electric gravel, stirring rapidly for 30 min;

[0049]S2, combined S1 straw - electric gravel mixture in 23oC is placed for 6 days to adjust;

[0050]S3, the straw-iron gravel mixture in S2 is naturally air-dried to water into 10% to prepare straw-electric gravel solids;

[0051]S4, a straw-monuctable solid of S3 is granulated under 10 MPa pressure, and a composite calcium-based deanger having a particle size of 2 cm is produced.

[0052]Place 10 prepared composite calcium-based desulfurizers in 850oIn the tube furnace of C, enter the simulated flue gas, and the smoke CO2, O2SO2The volume fraction is 15%, 3%, 0.3%, respectively, with N2In order to balance the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com