Self-flame-retardant PBT composite material and preparation method thereof

A composite material and flame-retardant technology, applied in the field of polymer synthesis, can solve the problems of PBT composite material structure stability reduction, flame-retardant effect to be improved, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

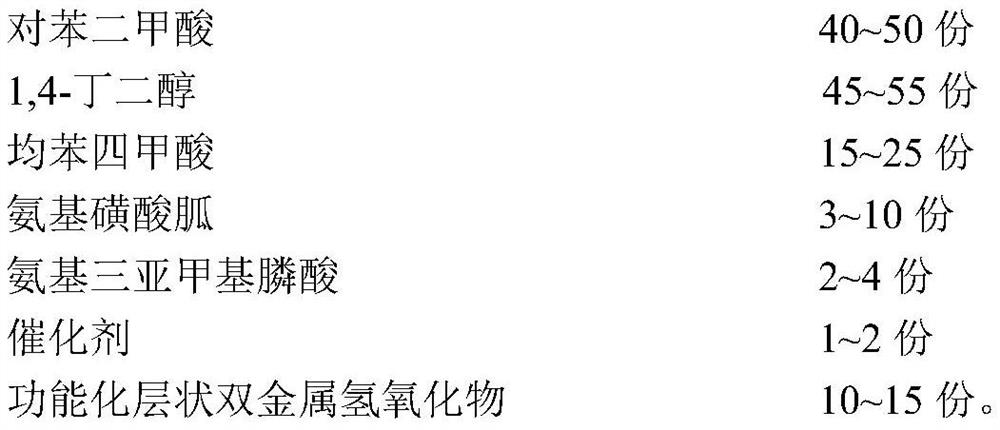

[0026] A self-flame-retardant PBT composite material, comprising the following raw materials in parts by mass:

[0027]

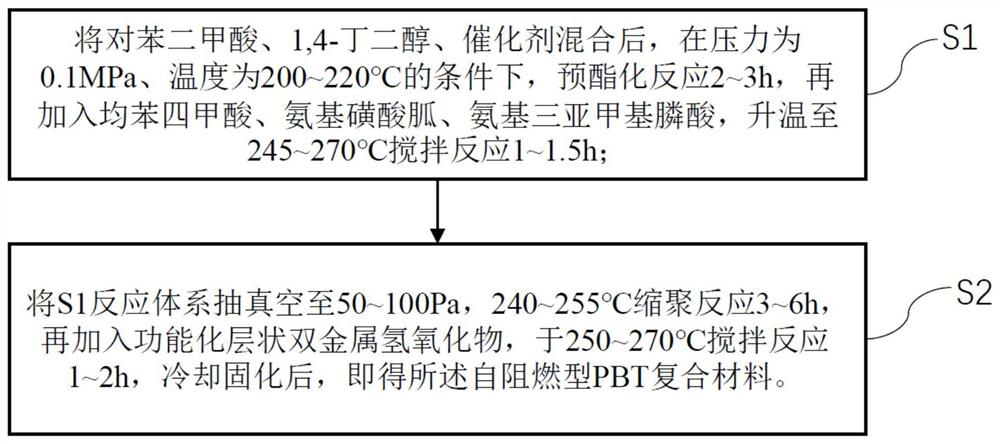

[0028] A preparation method of self-flame-retardant PBT composite material, comprising the following steps:

[0029] S1: Mix tetrabutyl titanate, 4-dimethylaminopyridine, and p-toluenesulfonic acid-doped polyaniline uniformly in a mass ratio of 1:0.1:0.3 to obtain a catalyst;

[0030] S2: Preparation of modified layered double metal hydroxide:

[0031] i: Intercalation modification: add nano-Mg / Al type layered double metal hydroxide to an aqueous solution with a mass concentration of 10% EDTA, control the solid-liquid ratio to 1g / 10mL, sonicate for 1h, filter, and dry to obtain EDTA Modified layered double metal hydroxide;

[0032] ii: Functional modification: Dissolve light stabilizer 622 in ethanol, add 2-ethylhexyl salicylate, mix well, then add the resulting mixture dropwise to EDTA modified layered double metal hydrogen Oxide, control the solid-l...

Embodiment 2

[0036] A self-flame-retardant PBT composite material, comprising the following raw materials in parts by mass:

[0037]

[0038] A preparation method of self-flame-retardant PBT composite material, comprising the following steps:

[0039] S1: Mix tetrabutyl titanate, 4-dimethylaminopyridine, and p-aminobenzenesulfonic acid-doped polyaniline uniformly in a mass ratio of 1:0.3:0.5 to obtain a catalyst;

[0040] S2: Preparation of modified layered double metal hydroxide:

[0041] i: Intercalation modification: adding nano-Ni / Al type layered double hydroxide to an aqueous solution with a mass concentration of 10% EDTA, controlling the solid-liquid ratio to 1g / 12.5mL, ultrasonic treatment for 1h, filtering, and drying to obtain EDTA modified layered double metal hydroxide;

[0042] ii: Functional modification: Dissolve light stabilizer 783 in ethanol, add 2-ethylhexyl salicylate, mix well, then add the resulting mixture dropwise to EDTA modified layered double metal hydrogen ...

Embodiment 3

[0046] A self-flame-retardant PBT composite material, comprising the following raw materials in parts by mass:

[0047]

[0048] A preparation method of self-flame-retardant PBT composite material, comprising the following steps:

[0049] S1: Mix tetrabutyl titanate, 4-dimethylaminopyridine, and phosphotungstic acid doped polyaniline uniformly at a mass ratio of 1:0.5:0.7 to obtain a catalyst;

[0050] S2: Preparation of modified layered double metal hydroxide:

[0051] i: Intercalation modification: add nano-Ni / Fe layered double metal hydroxide to an aqueous solution with a mass concentration of 10% EDTA, control the solid-liquid ratio to 1g / 15mL, ultrasonicate for 2 hours, filter, and dry to obtain EDTA Modified layered double metal hydroxide;

[0052] ii: Functional modification: Dissolve light stabilizer 944 in ethanol, add 2-ethylhexyl salicylate, mix well, then add the resulting mixture dropwise to EDTA modified layered double metal hydrogen Oxide, control the soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com