Thermoplastic polyurethane elastomer nanocomposite and preparation method thereof

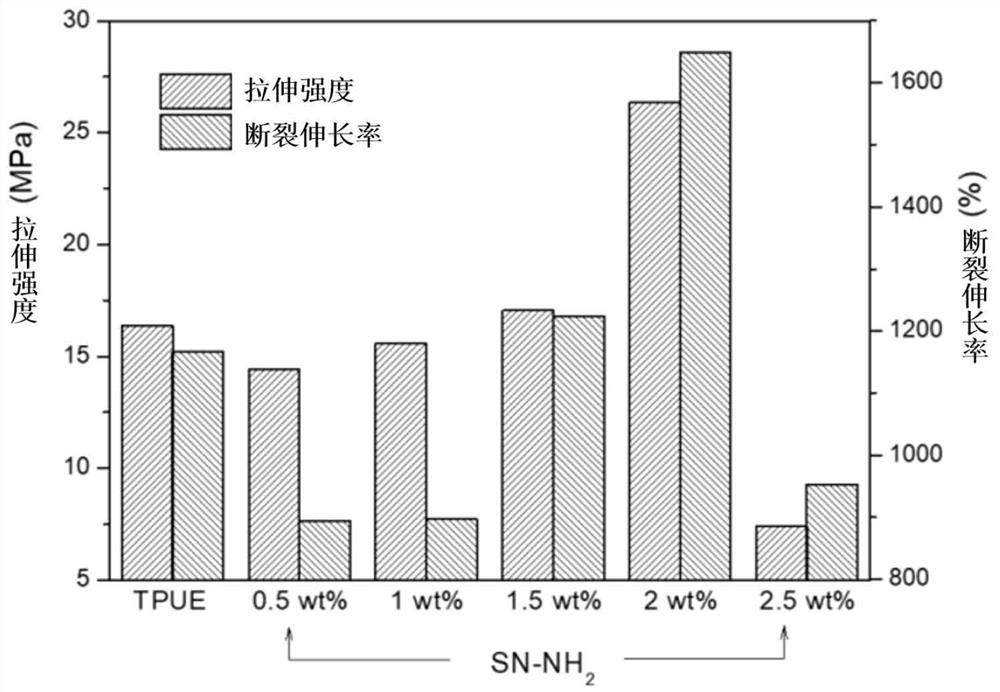

A technology of thermoplastic polyurethane and nanocomposite materials, which is applied in the field of modified polyurethane composite materials, can solve the problems of TPUE elongation at break decrease, etc., and achieve the effects of improving wear resistance, increasing strength, and maintaining elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

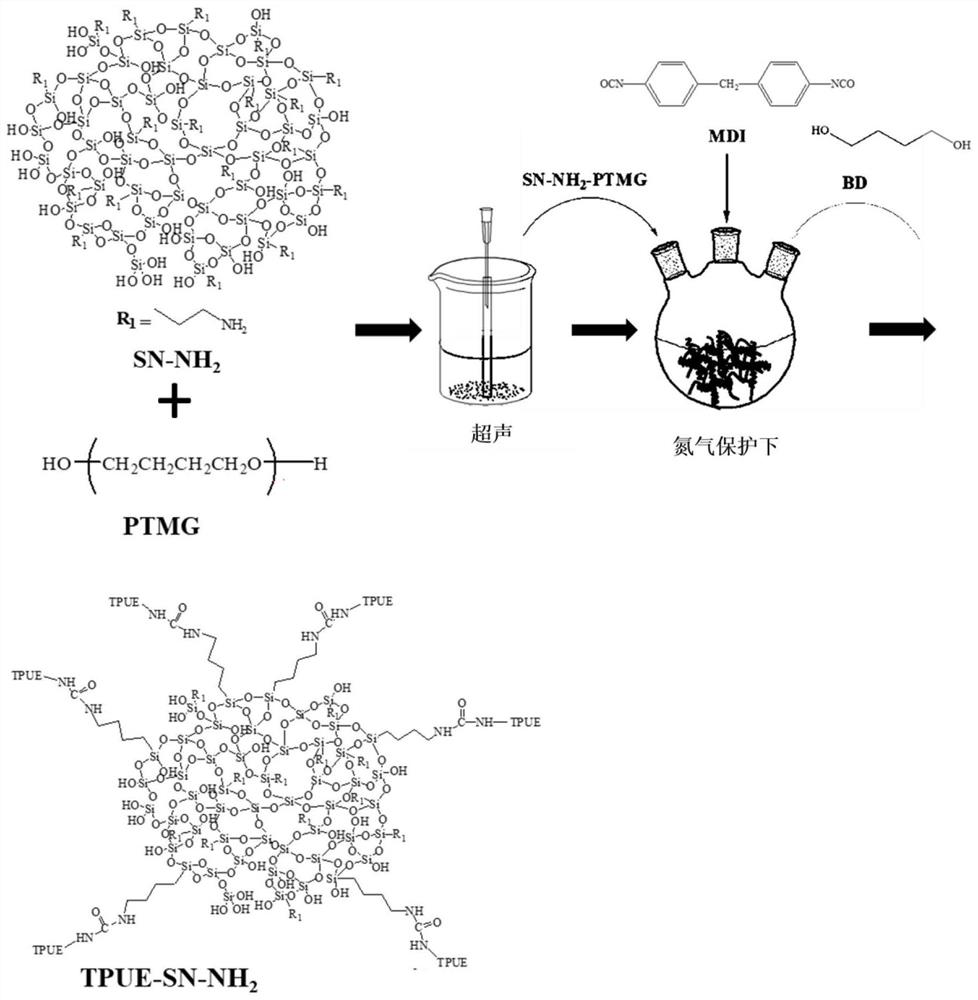

[0035] Simultaneously the application provides a kind of preparation method of thermoplastic polyurethane elastomer nanocomposite material, is used for preparing above-mentioned thermoplastic polyurethane elastomer nanocomposite material, mainly comprises the following several steps:

[0036] Step 1. Add reactive nano-silica to polyether polyol or polyester polyol, and perform ultrasonic dispersion;

[0037] Step 2, heating the dispersion liquid of nano-silica and polyether polyol or polyester polyol, and then adding diisocyanate into the dispersion liquid, mechanically stirring for 10-60 minutes in a nitrogen atmosphere; adding a chain extender, Keep the reaction temperature and mechanically stir for 5-10 minutes;

[0038] Step 3. Finally, the mixed system is poured into a polytetrafluoroethylene mold and solidified in an oven to obtain a thermoplastic polyurethane elastomer nanocomposite material.

[0039] The mass ratio of the amino nano-silica added in the above step 1 to t...

Embodiment 1

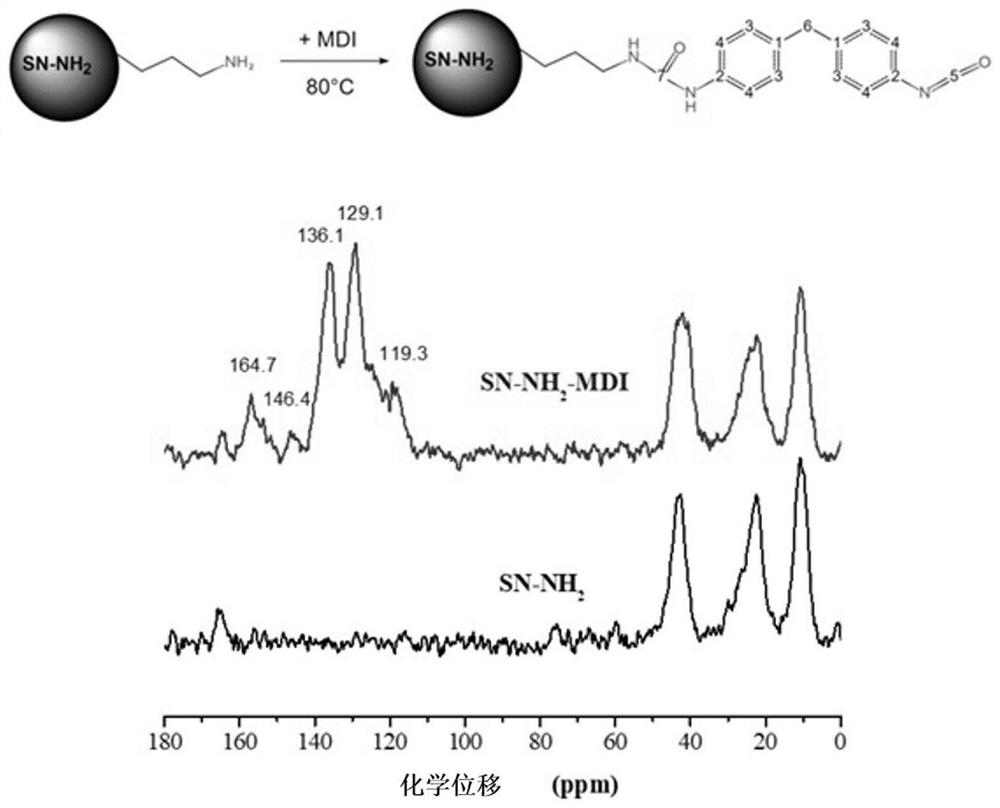

[0053] Step 1. Mix 1.3 grams of amino nano-silica SN-NH 2 Add in 200 grams of polytetramethylene ether glycol PTMG (number-average molecular weight 2000), and pre-disperse in PTMG for 20 minutes with a Vibra-Cell ultrasonic processor (VC750) with a 13mm standard probe and an amplitude of 250W ;

[0054] Step 2. Heat up the dispersion of amino nano-silica and PTMG to 80°C, then add 50 grams of MDI to the dispersion, and stir mechanically for 15 minutes in a nitrogen atmosphere; then add 9 grams of chain extender BOD to the system , mechanically stirred at 80°C for 5 minutes;

[0055] Step 3. Pour the mixed solution into a polytetrafluoroethylene mold and cure it in an oven at 80°C for 24 hours to obtain a thermoplastic polyurethane elastomer nanocomposite (TPUE / SN-NH 2 -0.5wt%), wherein the molar ratio MDI:PTMG:BOD=2:1:1, NCO:OH=1:1.

Embodiment 2

[0065] Step 1. First mix 2.6 grams of amino nano-silica SN-NH 2 Add in 200 grams of polytetramethylene ether glycol PTMG (number-average molecular weight 2000), under high-power ultrasound with the Vibra-Cell processor (VC750) that is equipped with a 13mm standard probe and an amplitude of 250W in PTMG. Disperse for 20 minutes;

[0066] Step 2. the dispersion liquid of amino nano silicon dioxide and PTMG is warmed up to 80 ℃, then 50 grams of dimethyl biphenyl diisocyanate (TODI) is joined in the dispersion liquid, mechanically stirred in nitrogen atmosphere 15 minutes; Then in Add 9 grams of chain extender 1,4-butanediol to the system, and mechanically stir at 80°C for 5 minutes;

[0067] Step 3. Finally, pour the mixed solution into a polytetrafluoroethylene mold, and cure it in an oven at 80°C for 24 hours to obtain a thermoplastic polyurethane elastomer nanocomposite (TPUE / SN-NH 2 -1.0wt%), wherein the molar ratio TODI:PTMG:1,4-butanediol=2:1:1, NCO:OH=1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com