Anti-blue-ray mobile phone camera lens and preparation process thereof

A mobile phone camera and anti-blue light technology, which is applied in optics, cameras, optical components, etc., can solve the problems of accelerating the aging rate of mobile phone camera lenses, poor light transmission and mechanical properties, and poor anti-ultraviolet performance, and achieve excellent anti-ultraviolet ability , Good anti-blue light performance, good light transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

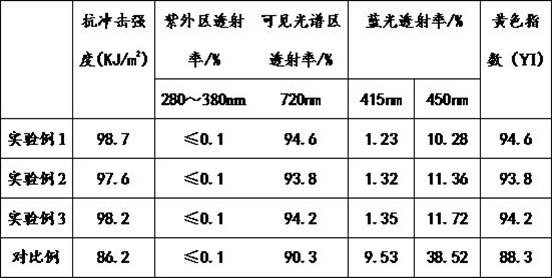

Examples

Embodiment 1

[0027] An anti-blue light mobile phone camera lens, which is composed of the following raw materials in weight fractions: 95 parts of polycarbonate, 0.16 part of metal oxide, 0.14 part of nanometer powder, 0.25 part of modified mica powder, and diisopropyl peroxydicarbonate 0.025 part of ester, 0.03 part of ultraviolet absorber, 0.6 part of blue light absorber, 0.03 part of antistatic agent and 0.015 part of toner.

[0028] The metal oxide is cerium oxide.

[0029] The nano-powder is made of fumed silica.

[0030] The preparation method of modified mica powder is:

[0031] Accurately weigh an appropriate amount of ultrafine mica powder and 2-(2-hydroxy-5-isoacrylate ethylphenyl)-2H-benzotriazole according to the mass ratio of 1:1.5, and place them in the reaction kettle , and then sequentially add ethyl acetate whose mass is 5 times that of the mixture in the kettle and isobutyltriethoxysilane whose mass is 15% of ultrafine mica powder to the reactor, premix and stir evenly,...

Embodiment 2

[0042]An anti-blue light mobile phone camera lens, which is composed of the following raw materials in weight fractions: 98 parts of polycarbonate, 0.3 part of metal oxide, 0.2 part of nanometer powder, 0.35 part of modified mica powder, and diisopropyl peroxydicarbonate 0.028 part of ester, 0.08 part of ultraviolet absorber, 1.0 part of blue light absorber, 0.05 part of antistatic agent and 0.02 part of toner.

[0043] The metal oxide is europium oxide.

[0044] Zirconia is selected as the nano powder.

[0045] The preparation method of modified mica powder is:

[0046] Accurately weigh an appropriate amount of ultrafine mica powder and 2-(2-hydroxy-5-isoacrylate ethylphenyl)-2H-benzotriazole according to the mass ratio of 1:1.6, and place them in the reaction kettle , and then sequentially add ethyl acetate whose mass is 6 times that of the mixture in the kettle and isobutyltriethoxysilane whose mass is 18% of ultrafine mica powder, and pre-mix and stir evenly, then add to...

Embodiment 3

[0057] An anti-blue light mobile phone camera lens, which is composed of the following raw materials in weight fractions: 100 parts of polycarbonate, 0.38 parts of metal oxide, 0.28 part of nanometer powder, 0.45 part of modified mica powder, and diisopropyl peroxydicarbonate 0.032 parts of ester, 0.12 parts of ultraviolet absorber, 1.5 parts of blue light absorber, 0.08 part of antistatic agent and 0.023 part of toner.

[0058] Neodymium oxide is selected as the metal oxide.

[0059] The nano-powder is made of fumed silica.

[0060] The preparation method of modified mica powder is:

[0061] Accurately weigh an appropriate amount of ultrafine mica powder and 2-(2-hydroxy-5-isoacrylate ethylphenyl)-2H-benzotriazole according to the mass ratio of 1:1.8, and place them in the reaction kettle , and then sequentially add ethyl acetate whose mass is 8 times that of the mixture in the kettle and isobutyltriethoxysilane whose mass is 22% of ultrafine mica powder, pre-mixed and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com