Slow-release fragrance-type antibacterial super-hydrophobic processing method for decorative paper

An antibacterial finishing and slow-release fragrance technology, applied in the post-treatment modification of cellulose pulp, paper, papermaking, etc., can solve the problems of difficult storage, strong taste of mugwort oil, unstable active ingredients, etc., and achieve good slow-release effect. , Good coating effect and long-lasting fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

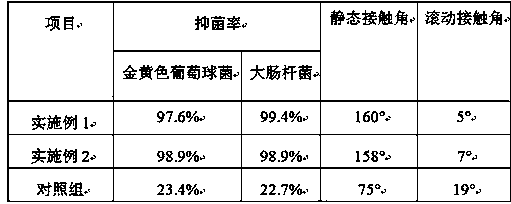

Examples

Embodiment 1

[0026] An antibacterial superhydrophobic finishing method for slow-release fragrance decorative paper, characterized in that it comprises the following steps, the following raw materials are by weight:

[0027] (1) Copying process of decorative base paper:

[0028] Soak 60 parts of bleached coniferous wood pulp and 40 parts of bleached hardwood pulp in water for 3 hours, use a beater to decompose for 20 minutes, and then start beating. Add 60 parts of titanium dioxide-kaolin composite suspension, 2 parts of wet strength agent and 0.06 parts of retention aid, after sheeting with a standard sheet former, vacuum-dry and balance moisture to obtain decorative base paper;

[0029] Among them, the preparation of titanium dioxide-kaolin composite suspension: dissolve 0.09 parts of dispersant sodium hexametaphosphate in water, add 15 parts of kaolin and 15 parts of titanium dioxide to disperse for 25 minutes, keep the grinding concentration at 45%, and then grind and coat for 30 minute...

Embodiment 2

[0038] An antibacterial superhydrophobic finishing method for slow-release fragrance decorative paper, characterized in that it comprises the following steps, the following raw materials are by weight:

[0039] (1) Copying process of decorative base paper:

[0040] Soak 75 parts of bleached coniferous wood pulp and 50 parts of bleached hardwood pulp in water for 4 hours, use a beater to disperse for 30 minutes, and then start beating. Add 76 parts of titanium dioxide-kaolin composite suspension, 2.5 parts of wet strength agent and 0.08 parts of retention aid, after sheeting with a standard paper former, vacuum-dry and balance moisture to obtain decorative base paper;

[0041] Among them, the preparation of titanium dioxide-kaolin composite suspension: dissolve 0.11 parts of dispersant sodium hexametaphosphate in water, add 19 parts of kaolin and 19 parts of titanium dioxide to disperse for 35 minutes, keep the grinding concentration at 55%, and then grind and coat for 40 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tightness | aaaaa | aaaaa |

| Tear index | aaaaa | aaaaa |

| Burst index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com