Acetone-removing silicon rubber and preparation method thereof

A technology for removing acetone and silicone rubber, which is applied to the field of deacetone silicone rubber and its preparation, can solve the problems of high price, untimely supply, and heat-conducting products cannot meet the requirements for use, and achieves the effect of increasing the filling amount and improving the heat-conducting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

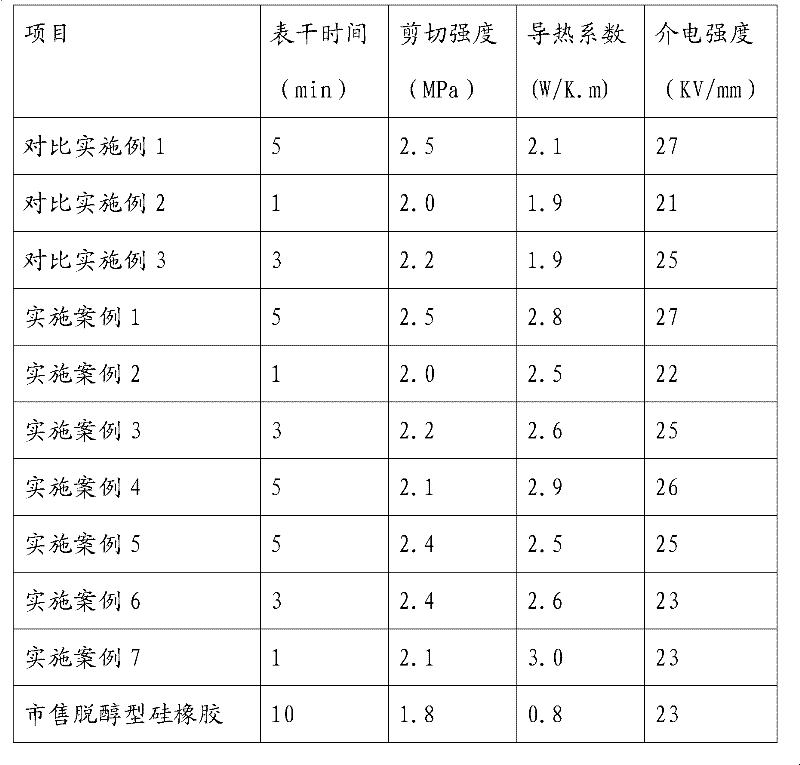

Examples

Embodiment 1

[0028] Weigh each raw material according to the following weight ratio, 5000mPa.s hydroxyl-terminated polydimethylsiloxane 1000g, 1000mPa.s dimethyl silicone oil 200g, 30μm spherical alumina 10000g, diameter 0.5μm, aspect ratio 10: 0.5 zinc oxide whiskers 10g, methyl triisopropenyloxysilane 50g, white carbon black 100g, 1,1,3,3-tetramethylguanidinopropyltrimethoxysilane 5g, γ-aminopropyl trimethoxysilane Add 10g of ethoxysilane into a 5L planetary mixer one by one, evacuate to -0.098Mpa, disperse at a speed of 400rpm, mix for 1 hour, let it air naturally at room temperature, and pack it.

Embodiment 2

[0030] Weigh each raw material according to the following weight ratio, 80000mPa.s hydroxyl-terminated polydimethylsiloxane 1000g, 1000mPa.s dimethyl silicone oil 500g, 50μm spherical aluminum nitride 5000g, diameter 5μm, aspect ratio 10: 1 zinc oxide whisker 50g, vinyl triisopropenyloxysilane 100g, white carbon black 60g, 1,1,3,3-tetramethylguanidinopropyltriethoxysilane 20g, γ-aminopropyl Add 20g of triethoxysilane into a 5L planetary mixer one by one, evacuate to -0.1Mpa, mix for 1.5 hours at a speed of 600rpm dispersing disc, let it air naturally at room temperature, and pack it.

Embodiment 3

[0032] Weigh each raw material according to the following weight ratio, 1000g of 20000mPa.s hydroxyl-terminated polydimethylsiloxane, 350g of 500mPa.s dimethyl silicone oil, 5000g of 50μm spherical alumina, 3000g of 1μm spherical alumina, carbon nanotubes 25g, phenyltriisopropenyloxysilane 80g, white carbon black 80g, 1,1,3,3-tetramethylguanidinopropyltrimethoxysilane 13g, γ-aminopropyltriethoxysilane 15g, Put them into a 5L planetary mixer one by one, evacuate to -0.099Mpa, mix for 2 hours at the speed of 500rpm dispersing disc, let it air naturally at room temperature, and pack it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com