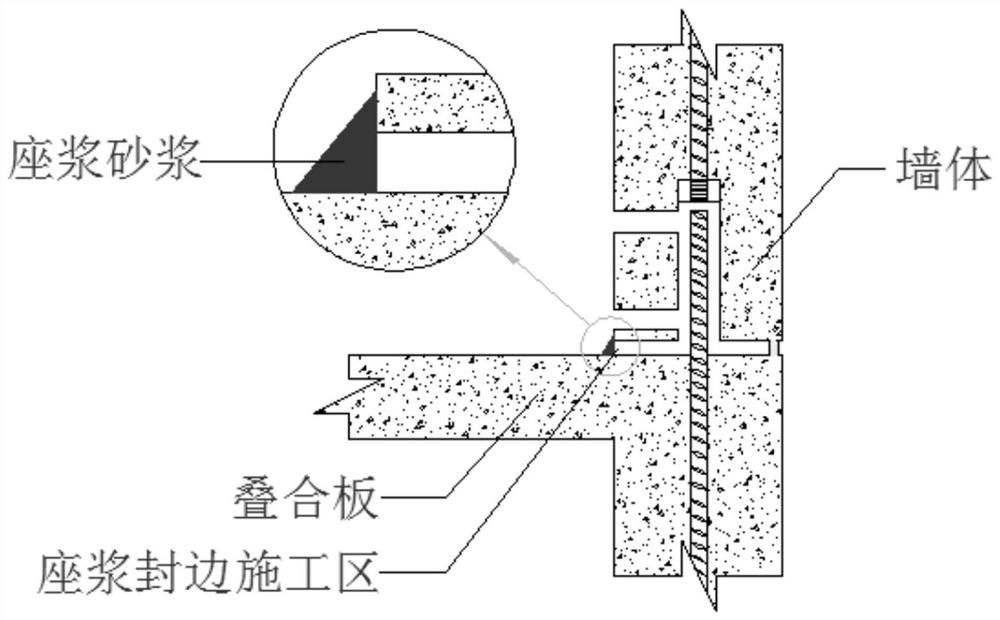

Seat mortar for low-temperature prefabricated buildings and preparation method thereof

A prefabricated and architectural technology, applied in the field of building materials, to achieve the effects of ensuring quality and safety, compensating shrinkage, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

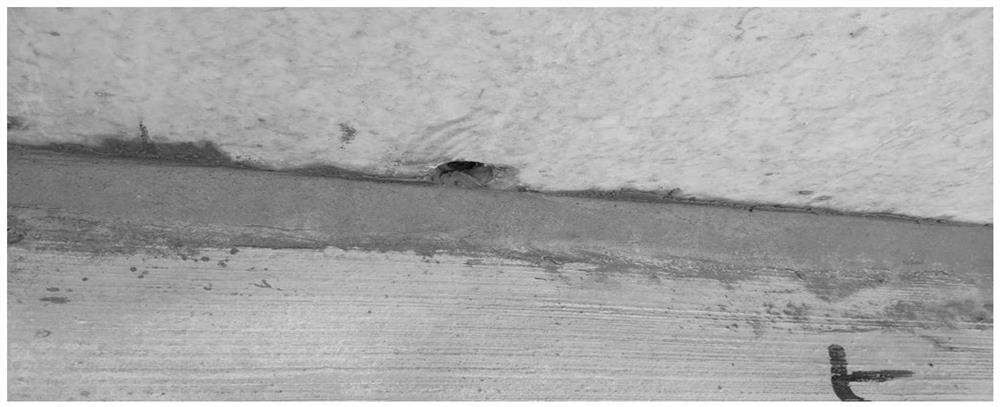

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The low-temperature type prefabricated building block mortar provided in this embodiment, its raw materials include 10wt% of ordinary cement, 40wt% of special cement, 42wt% of aggregate, 4wt% of mineral admixture, 0.13wt% of plastic expansion component, expansion agent 2wt%, setting modifier 0.17wt%, antifreeze 1wt%, construction performance improver 0.6wt%, admixture 0.1wt%.

[0038] The weight ratio of the raw material azo compound of the plastic expansion agent and the tribasic lead sulfate is 1:1. The weight ratio of the raw material early strength agent and the setting retarder of the set control agent is 1:1.

Embodiment 2

[0040] The low-temperature type prefabricated building block mortar provided in this embodiment, its raw materials include ordinary cement 5wt%, special cement 50wt%, aggregate 35wt%, mineral admixture 10.29wt%, plastic expansion component 0.01wt%, expansion 2 wt % of agent, 1 wt % of setting modifier, 1 wt % of antifreeze, 0.6 wt % of workability improver, and 0.1 wt % of admixture. The raw materials and mass ratios of the plastic expansion agent and the setting modifier are the same as those in Example 1.

Embodiment 3

[0042] The low-temperature prefabricated building block mortar provided in this embodiment includes 15wt% of ordinary cement, 27.25wt% of special cement, 50wt% of aggregate, 3wt% of mineral admixture, 1wt% of plastic expansion component, and expansion agent. 2wt%, setting modifier 0.05wt%, antifreeze 1wt%, construction performance improver 0.6wt%, admixture 0.1wt%. The raw materials and mass ratios of the plastic expansion agent and the setting modifier are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com