Method for preparing reduced ilmenite for welding electrodes by reducing marine placer through microwaves of rotary hearth furnace

A technology of sea sand ore and rotary hearth furnace, which is applied in chemical instruments and methods, magnetic separation, solid separation, etc. It can solve the problems of long reduction period and weak reduction intensity, and achieve the purpose of increasing the contact area of materials, increasing the reaction intensity, The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

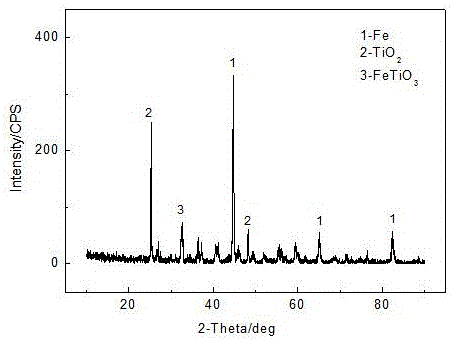

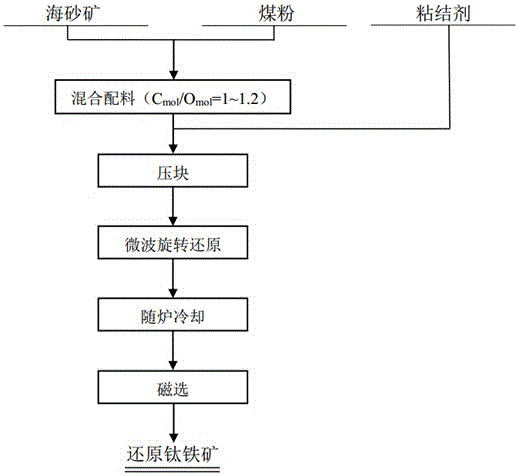

[0022] Such as figure 1 Shown, this rotary hearth furnace microwave reduction sea sand ore prepares the method for reducing ilmenite for welding rod, and its concrete steps are as follows:

[0023] (1) Mixing ingredients and briquetting: first, 100g sea sand ore (Australian sea sand ore provided by a titanium factory in Tianjin is used, and its chemical composition is TiO by mass percentage 2 50.71%, TFe32.18%, FeO25.77%, SiO 2 0.79%, MgO1.05%, CaO0.28%, Al 2 o 3 0.69%, P0.058% and S0.009%, the particle size is less than 200 mesh) and coal powder (anthracite coal powder sold in the market, its main components are calculated by mass percentage, volatile content is 9.21%, ash content is 13.43%, fixed carbon 72.56%, the particle size is less than 200 mesh) according to the molar ratio of the oxygen in the iron oxide in the sea sand ore and the carbon in the coal powder is 1:1, the mixture is obtained, and then 1% of the mixture mass is added to the mixture Mix the binder (bin...

Embodiment 2

[0028] Such as figure 1 Shown, this rotary hearth furnace microwave reduction sea sand ore prepares the method for reducing ilmenite for welding rod, and its concrete steps are as follows:

[0029] (1) Mixing ingredients and briquetting: first, 100g sea sand ore (Australian sea sand ore provided by a titanium factory in Tianjin is used, and its chemical composition is TiO by mass percentage 2 50.71%, TFe32.18%, FeO25.77%, SiO 2 0.79%, MgO1.05%, CaO0.28%, Al 2 o 3 0.69%, P0.058% and S0.009%, the particle size is less than 200 mesh) and coal powder (anthracite coal powder sold in the market, its main components are calculated by mass percentage, volatile content is 9.21%, ash content is 13.43%, fixed carbon 72.56%, the particle size is less than 200 mesh) according to the molar ratio of the oxygen in the iron oxide in the sea sand ore and the carbon in the coal powder is 1:1.2, the mixture is obtained, and then 1.5% of the mixture mass is added to the mixture The binder (the...

Embodiment 3

[0034] Such as figure 1 Shown, this rotary hearth furnace microwave reduction sea sand ore prepares the method for reducing ilmenite for welding rod, and its concrete steps are as follows:

[0035](1) Mixing ingredients and briquetting: first, 100g sea sand ore (Australian sea sand ore provided by a titanium factory in Tianjin is used, and its chemical composition is TiO by mass percentage 2 50.71%, TFe32.18%, FeO25.77%, SiO 2 0.79%, MgO1.05%, CaO0.28%, Al 2 o 3 0.69%, P0.058% and S0.009%, the particle size is less than 200 mesh) and coal powder (anthracite coal powder sold in the market, its main components are calculated by mass percentage, volatile content is 9.21%, ash content is 13.43%, fixed carbon 72.56%, the particle size is less than 200 mesh) according to the molar ratio of the oxygen in the iron oxide in the sea sand ore and the carbon in the coal powder is 1:1.1, the mixture is obtained, and then 2% of the mixture mass is added to the mixture The binder (the bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com