Method for reducing pyrolusite by carrying out microwave heating on biomass

A microwave heating and biomass technology, which is applied in metallurgy and microwave heating biomass reduction pyrolusite field, can solve the problem of high equipment requirements, achieve the effect of increasing material contact area, increasing reaction intensity, and improving energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

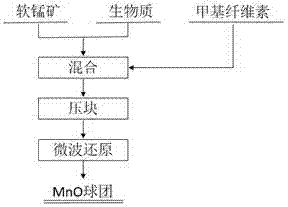

Image

Examples

Embodiment 1

[0036] A method for reducing pyrolusite by microwave heating biomass, the implementation steps of this embodiment are as follows:

[0037] The raw material pyrolusite is firstly analyzed, and its chemical composition is MnO by weight 2 22.4% and FeO 8.4%; the particle size of the pyrolusite after sieving is not greater than 200 mesh (0.074 mm).

[0038] The raw biomass was industrially analyzed, and its chemical composition was 66.19% volatile matter, 10.81% ash, 14.08% fixed carbon and 8.92% moisture; mm).

[0039] A. Mixed ingredients

[0040] The pyrolusite and biomass are mixed with a mass ratio of 1:10, and then

[0041] B. briquetting

[0042] Add 1% methyl cellulose by weight to the pyrolusite and biomass mixture, mix evenly, moisten it, put it into a special mold, make green pellets under 25 MPa pressure, and put it in an oven to dry for 12 h above;

[0043] C, microwave reduction

[0044] After the green pellets obtained in step B were put into a corundum cruc...

Embodiment 2

[0047] A method for reducing pyrolusite by microwave heating biomass, the implementation steps of this embodiment are as follows:

[0048] The raw material pyrolusite is firstly analyzed, and its chemical composition is MnO by weight 2 31.2% and FeO 23.7%; the particle size of the pyrolusite after sieving is not greater than 200 mesh (0.074 mm).

[0049] The raw biomass was industrially analyzed, and its chemical composition was 66.19% by weight of volatile matter, 10.81% of ash, 14.08% of fixed carbon and 8.92% of moisture; the particle size of the biomass after screening was not greater than 200 mesh (0.074 mesh). mm).

[0050] A. Mixed ingredients

[0051] The pyrolusite and biomass are mixed with a mass ratio of 2:10, and then

[0052] B. briquetting

[0053] Add 1% methyl cellulose by weight to the pyrolusite and biomass mixture, mix evenly, moisten it, put it into a specific mold, make green pellets under 25 MPa pressure, and put it in an oven to dry for 12 h above...

Embodiment 3

[0058] A method for reducing pyrolusite by microwave heating biomass, the implementation steps of this embodiment are as follows:

[0059] The raw material pyrolusite is firstly analyzed, and its chemical composition is MnO by weight 2 31.2% and FeO 23.7%; the particle size of the pyrolusite after sieving is not greater than 200 mesh (0.074 mm).

[0060] The raw biomass was industrially analyzed, and its chemical composition was 79.6% volatile matter, 0.87% ash, 13.02% fixed carbon and 6.51% moisture; mm).

[0061] A. Mixed ingredients

[0062] The pyrolusite and biomass are mixed with a mass ratio of 2:10, and then

[0063] B. briquetting

[0064] Add 1% methyl cellulose by weight to the pyrolusite and biomass mixture, mix evenly, moisten it, put it into a special mold, make green pellets under 25 MPa pressure, and put it in an oven to dry for 12 h above;

[0065] C, microwave reduction

[0066] After the green pellets obtained in step B were put into a corundum cruci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com