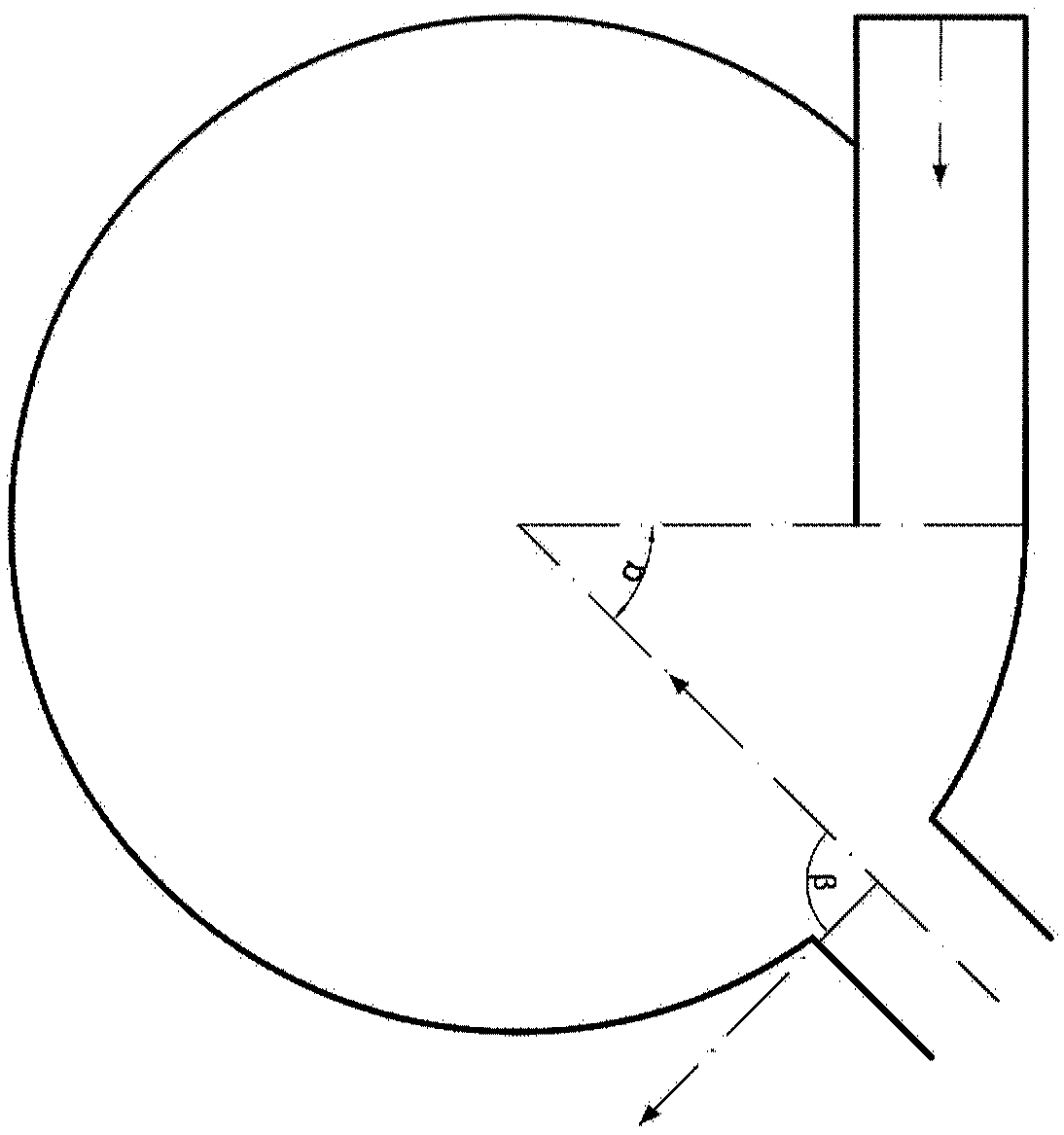

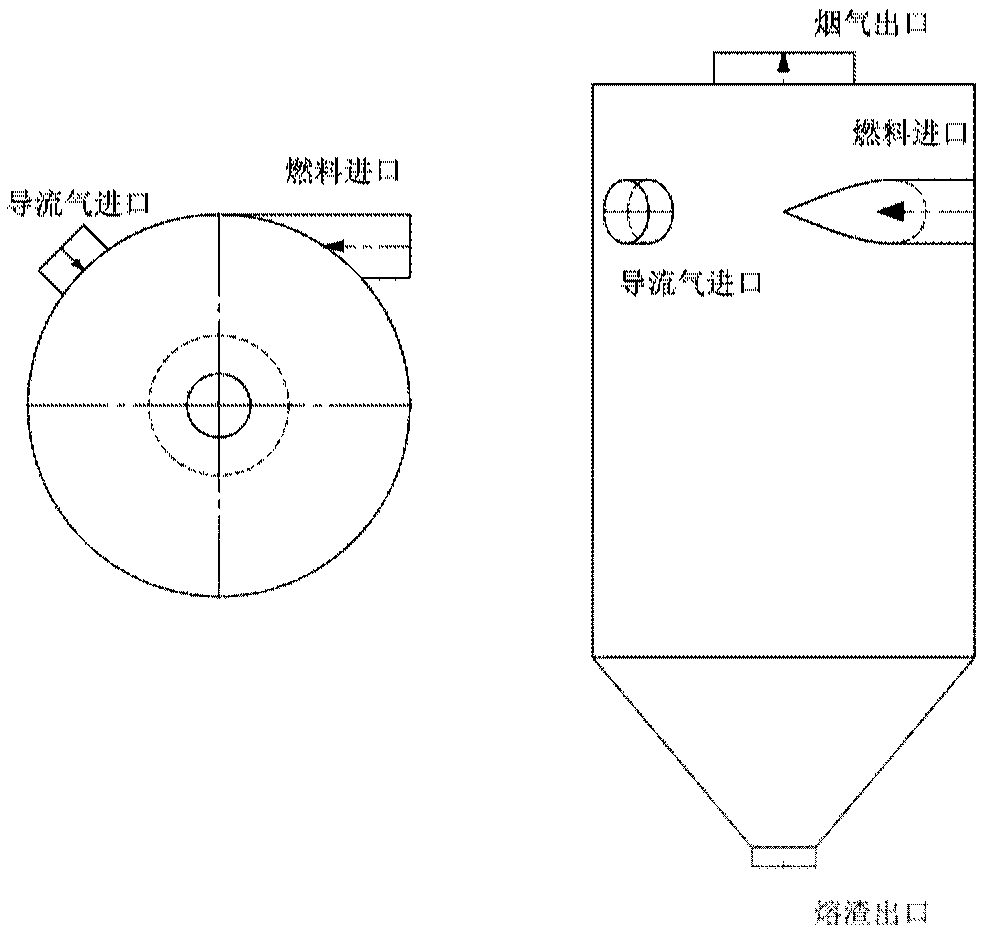

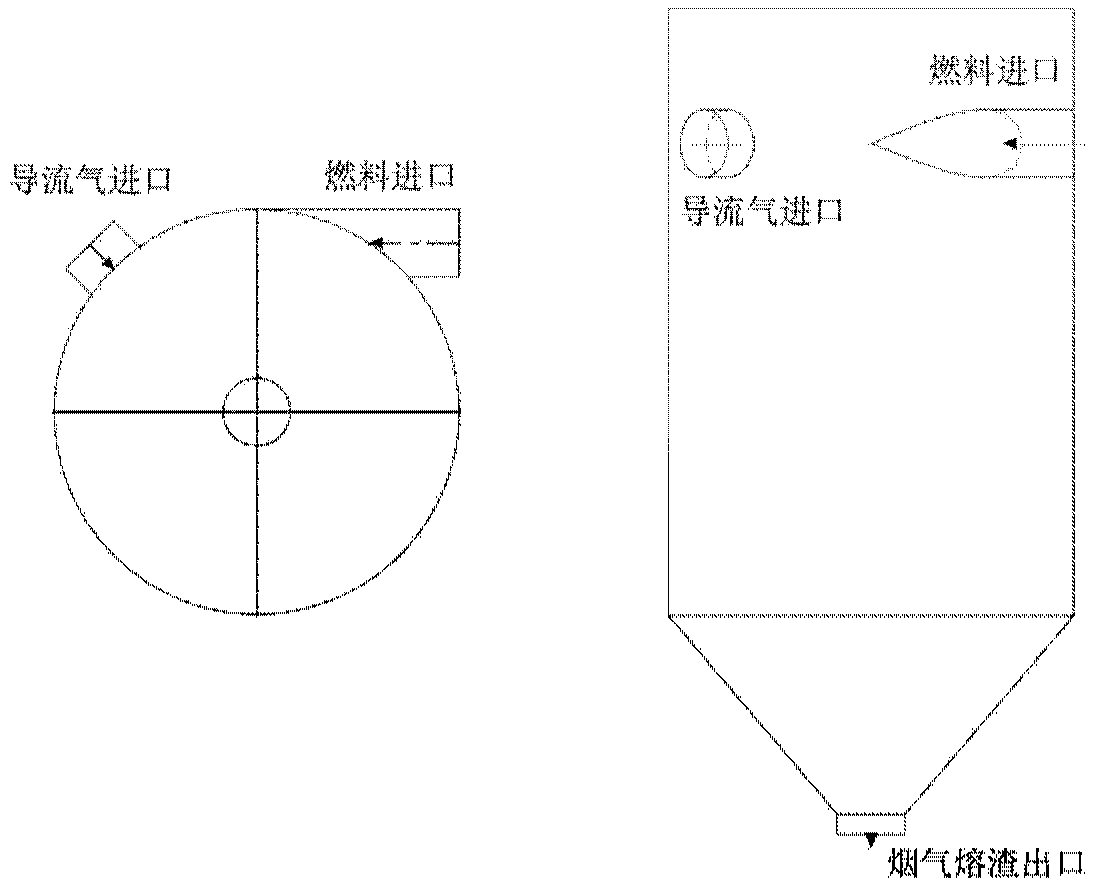

Cyclone melting furnace and using method thereof

A melting furnace and cyclone technology, applied in the application field of cyclone melting furnace, can solve the problems of wear of refractory material, high airflow speed and high strength of cyclone furnace, and achieve the effect of reducing direct scouring, strengthening reaction intensity and increasing flow field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. Hereinafter, some examples will be provided to illustrate the embodiments of the present invention in detail. The advantages and effects of the present invention will be more obvious through the following content of the present invention. The drawings accompanying this description are simplified and used for illustration purposes. The number, shape and size of the components shown in the drawings can be modified according to the actual situation, and the configuration of the components may be more complicated. Other aspects of practice or application can also be carried out in the present invention, and various changes and adjustments can be made without departing from the defined spirit and scope of the present invention....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com