Cooling device for 1500°C ultra-high temperature valve body

A cooling device, ultra-high temperature technology, applied in the direction of valve heating/cooling device, valve device, valve details, etc., can solve the problem that the valve cannot be manufactured, the heat loss of the medium is large, and the properties of non-metallic materials cannot meet the requirements of rapid cooling, rapid heating and high pressure. Working conditions and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

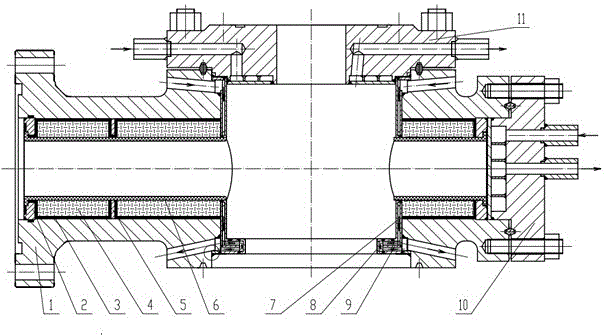

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] The applicable valve of the present invention is an angle structure, and the high-temperature medium enters from the inlet end of the upper end of the valve and is discharged from the lower end of the valve.

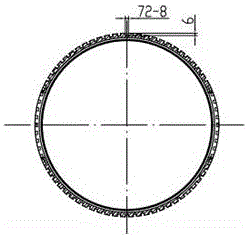

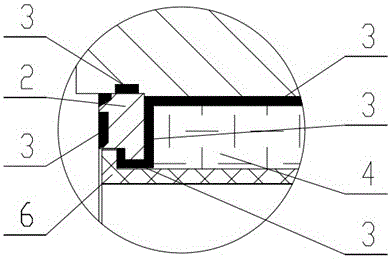

[0036] A cooling device for a 1500°C ultra-high temperature valve body, including a medium inlet channel on the valve body 1 and a middle mouth of the valve body, the two are connected, a valve cover 11, an end cover 10, the valve body on the valve body The medium inlet channel is equipped with a high-temperature ceramic heat-insulating lining cooling structure, and the middle port of the valve body is equipped with a water cooling system for the middle port of the valve body. The water-cooling system in the middle of the valve body includes a water-cooling inner layer in the middle of the valve body and a water-cooling device in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com