Patents

Literature

37results about How to "Reduce medium temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

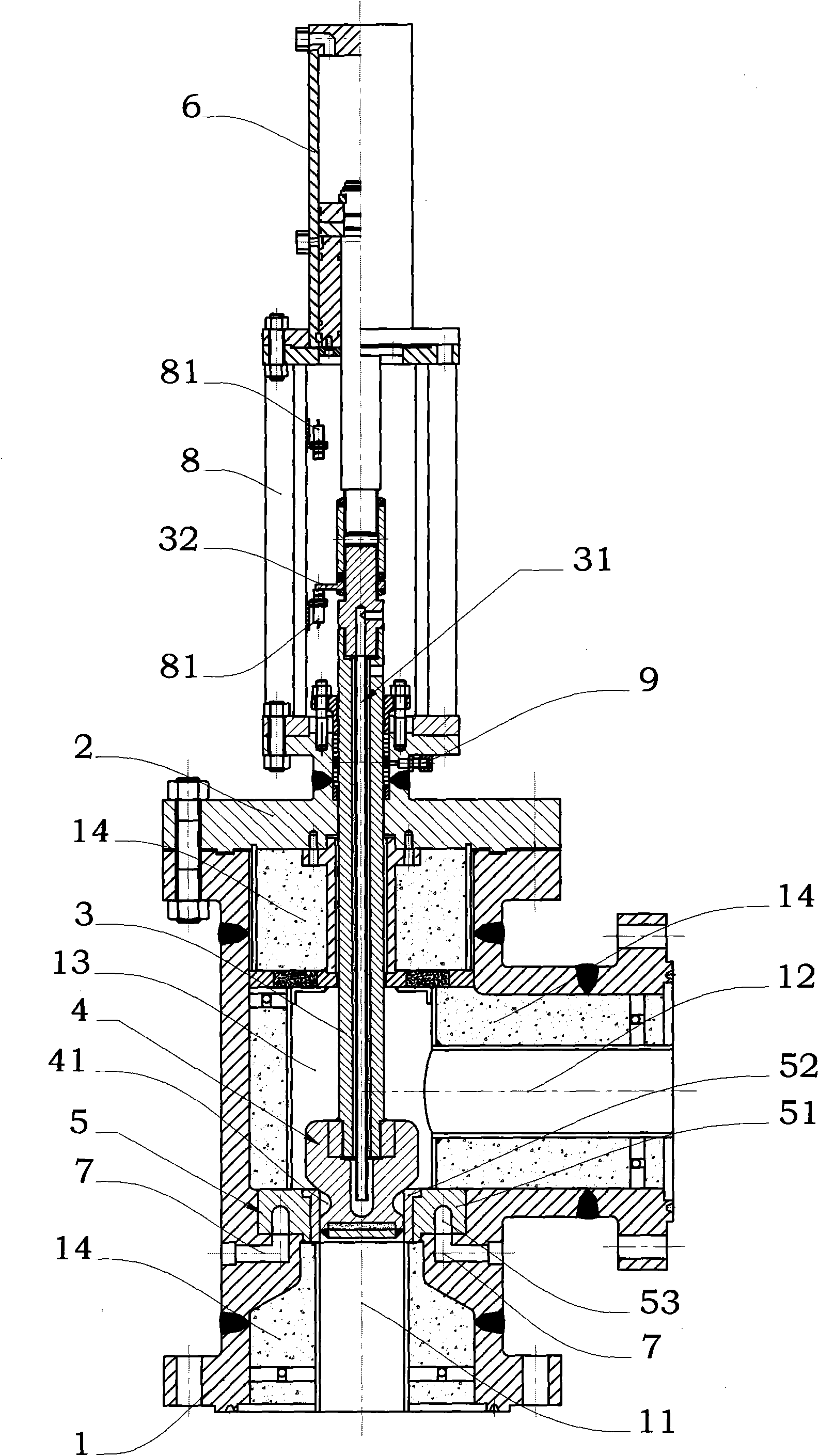

Ultra-temperature high-pressure stop valve

ActiveCN101608694AImprove sealingIt will not affectValve members for heating/coolingLift valveEngineeringHigh pressure

The invention relates to an ultra-temperature high-pressure stop valve comprising a valve body, a valve cover, a valve rod, a valve clack, a valve seat and an operation mechanism, wherein, cooling channels are arranged in the valve rod and the valve clack. The invention is characterized in that at least two groups of sealing surfaces are arranged between the valve clack and the valve seat; the valve clack is provided with an annular notch separating adjacent sealing surfaces, and the two ends of the notch are stuck with the inner wall of a valve seat path to form an insulated tank. The invention has the following beneficial effects: a plurality of groups of sealing surfaces are arranged between the valve clack and the valve seat, and the insulated tank is arranged between two adjacent sealing surfaces; if an outer sealing surface leaks, medium enters the insulated tank but is blocked by the outer sealing surface, so that the heat quantity of medium entering the insulated tank is small; because the insulated tank is near the valve rod and the cooling path of the valve clack, the temperature of the medium entering the insulated tank can be quickly lowered, which effectively ensures that inner sealing surface can be free from being affected by high-temperature and high-pressure medium, and the whole sealing performance of the valve can be improved.

Owner:ZHEJIANG PETROCHEMICAL VALVE CO LTD

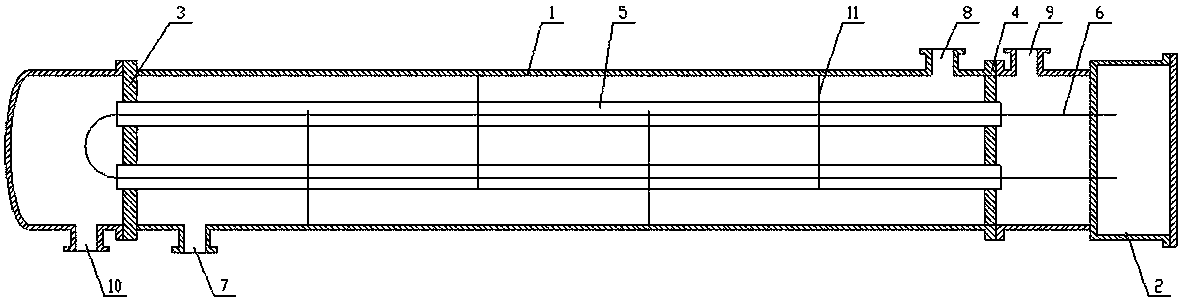

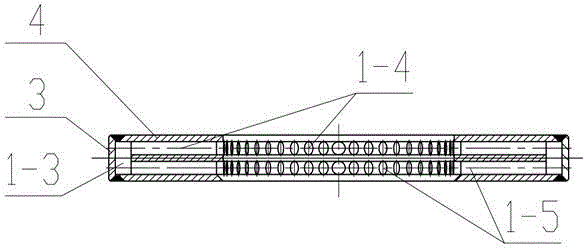

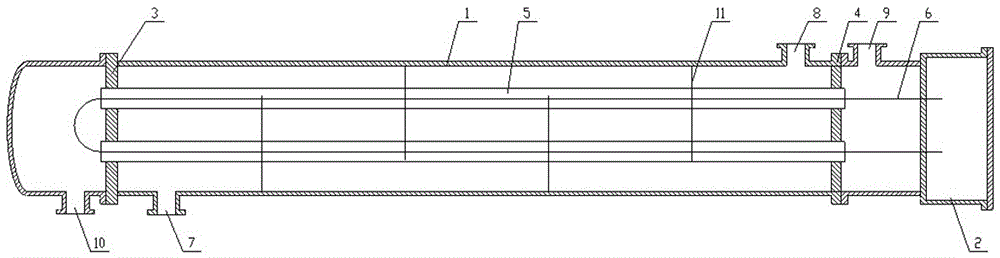

Energy saving heat exchanger

ActiveCN103743087AReduce surface temperatureExtended service lifeWater heatersEngineeringMicro heat exchanger

The invention relates to the technical field of heat exchange, in particular to an energy saving heat exchanger comprising a shell 1. One end of the shell 1 is provided with a terminal box 2, a first tube plate 3 and a second tube plate 4 which are perpendicular to the axis of the shell are arranged in the shell 1, a heat exchanging tube 5 is arranged between the first tube plate 3 and the second tube plate 4 and penetrates the same, an electrical heating tube 6 connected with the terminal box 2 is arranged in the heat exchanging tube 5, a shell inlet 7 and a shell outlet 8 are formed in the shell between the first tube plate 3 and the second tube plate 4, a tube inlet 9 is formed in the shell between the second tube plate 4 and the terminal box 8, and a tube outlet 10 is formed in the shell between the first tube plate 3 and the bottom of the shell. The energy saving heat exchanger is applied in the field of heat exchangers, and has the advantages that additional hot fluid medium is omitted, control is facilitated, energy can be saved, and service life is long.

Owner:无锡华能电热器材有限公司

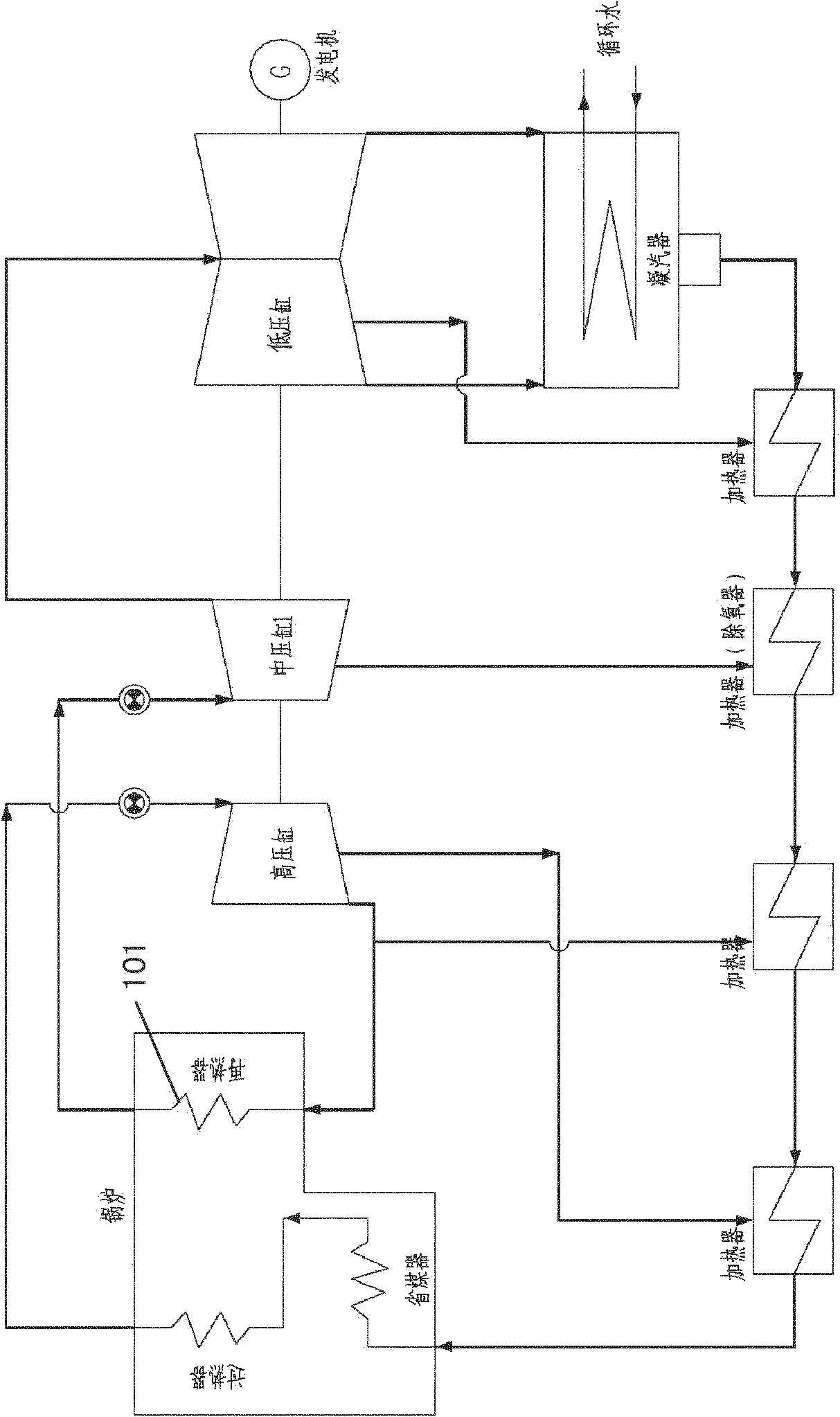

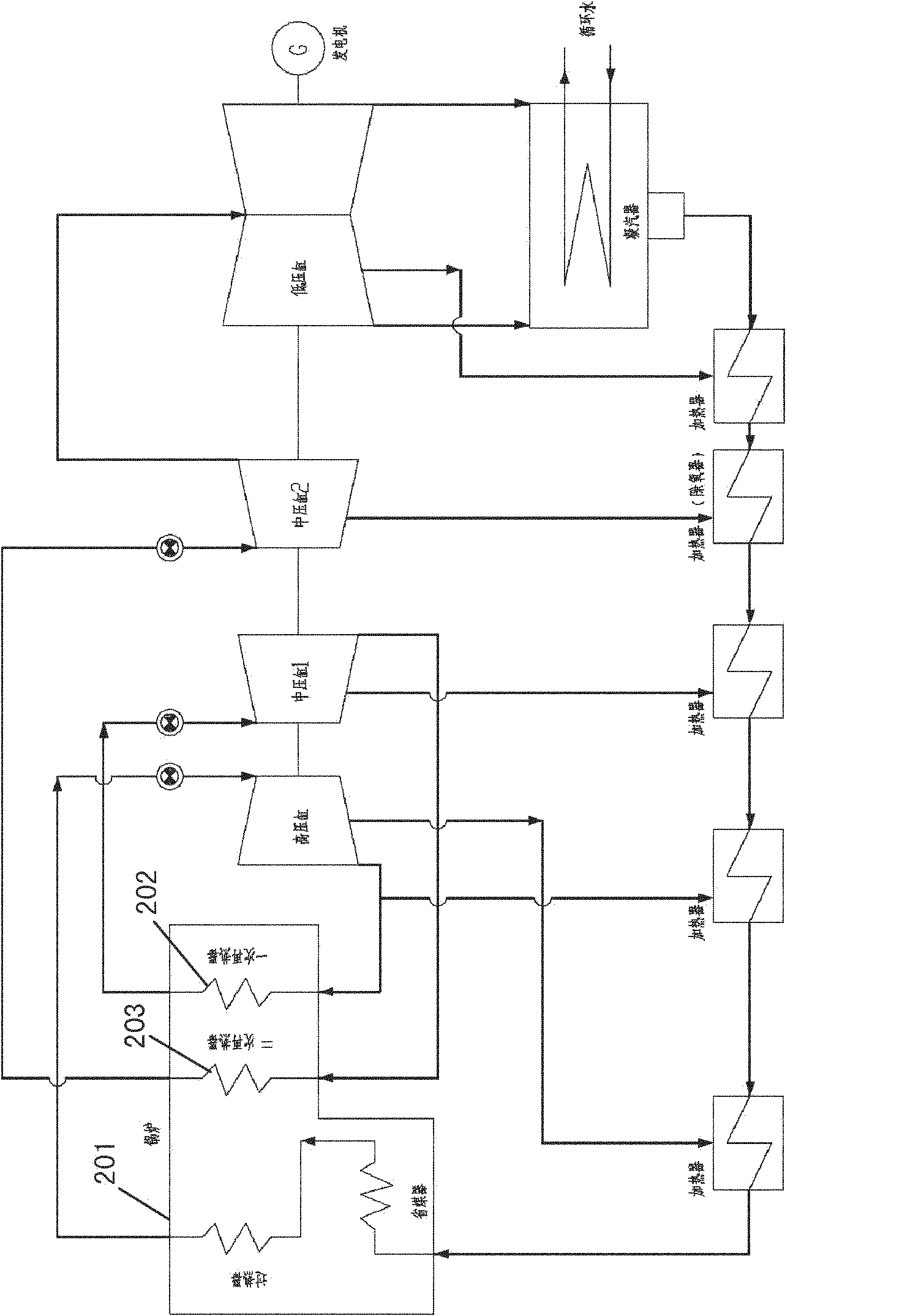

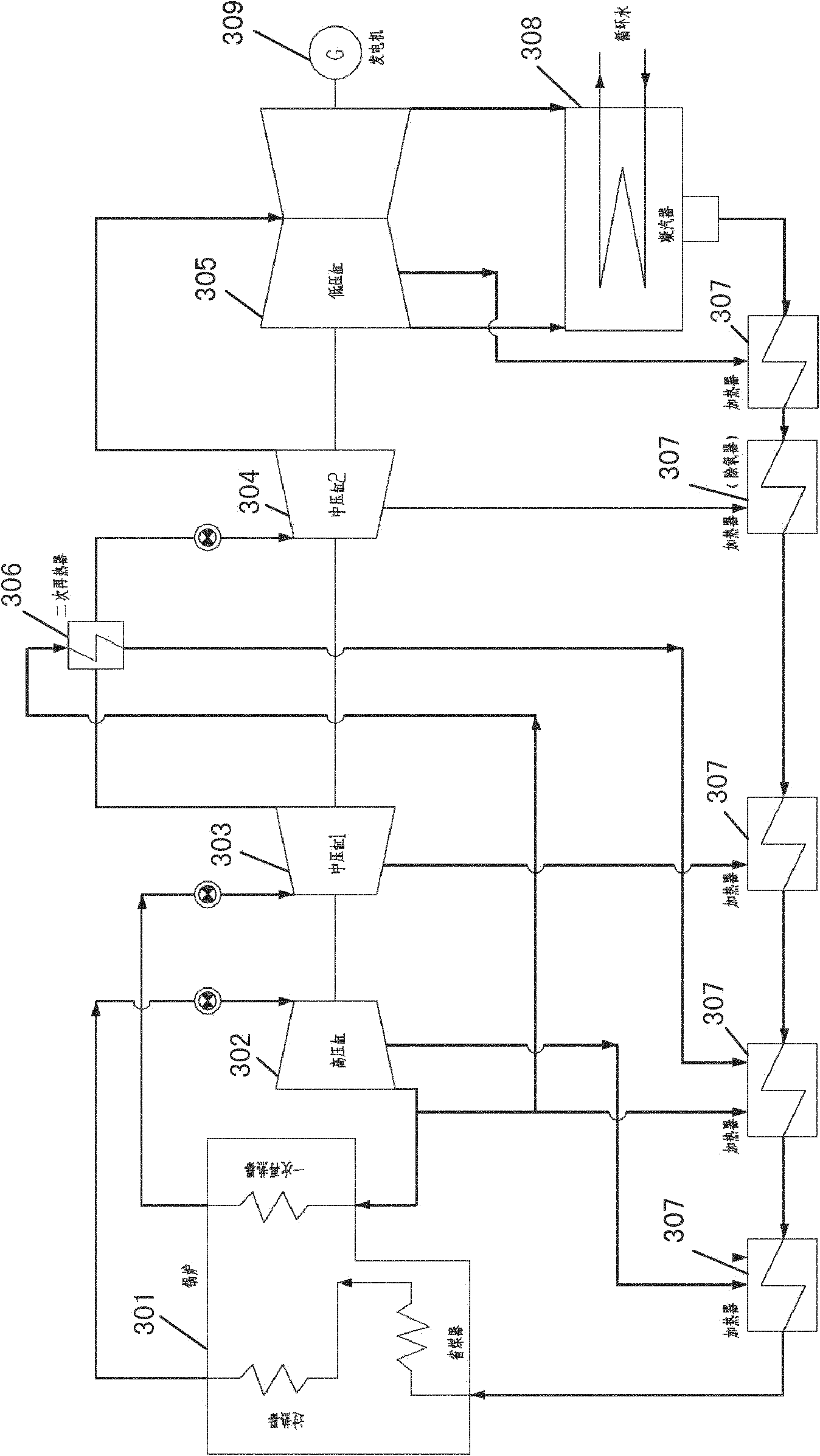

Steam secondary reheating system

InactiveCN102486308AImprove thermal cycle efficiencySmall flow resistanceMachines/enginesSteam superheatersEngineeringHeating system

The invention provides a steam secondary heating system. The system comprises a steam turbine and a secondary reheater, wherein the steam turbine comprises a high-pressure cylinder, intermediate-pressure cylinders and a low-pressure cylinder which are connected in sequence; the secondary reheater is arranged on the exterior of a boiler, and is connected with the exhaust port of one intermediate-pressure cylinder of the steam turbine and the air inlet of the other intermediate-pressure cylinder or the low-pressure cylinder of the steam turbine; the secondary reheater produces high-temperature reheated steam, and introduces the high-temperature reheated steam into the other intermediate-pressure cylinder or the low-pressure cylinder. According to the steam secondary reheating system provided by the invention, the investment on the secondary reheating system is greatly reduced while the efficiency is improved, so that the steam secondary reheating system has the advantages of excellent investment income and technique economical efficiency.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

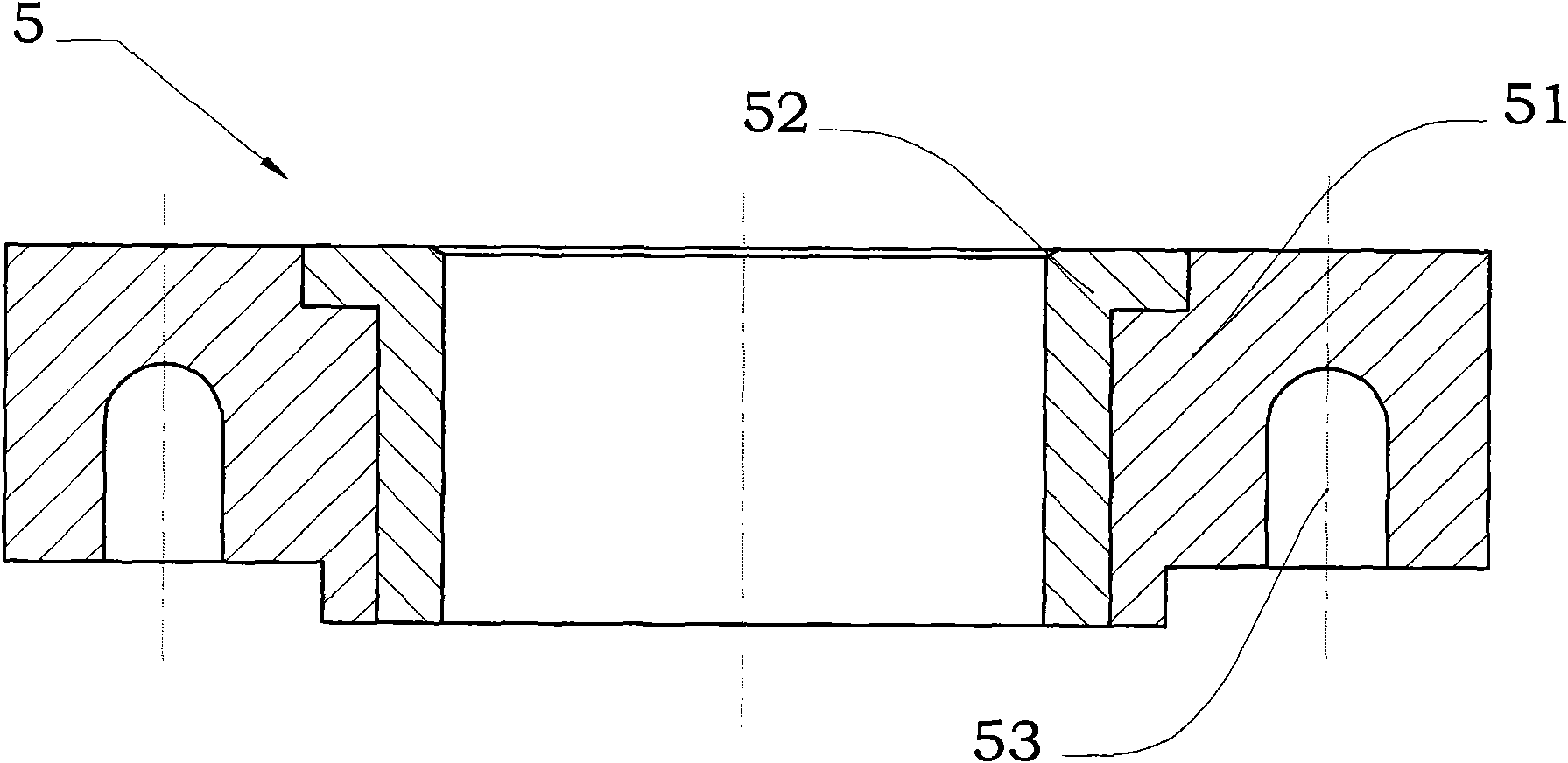

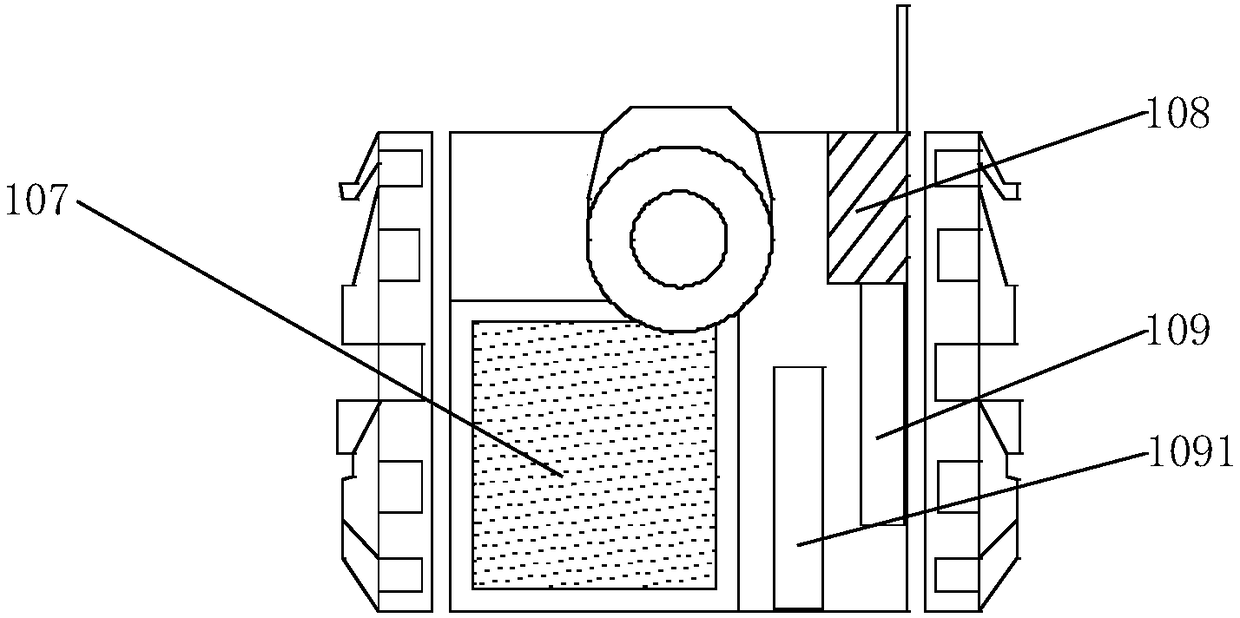

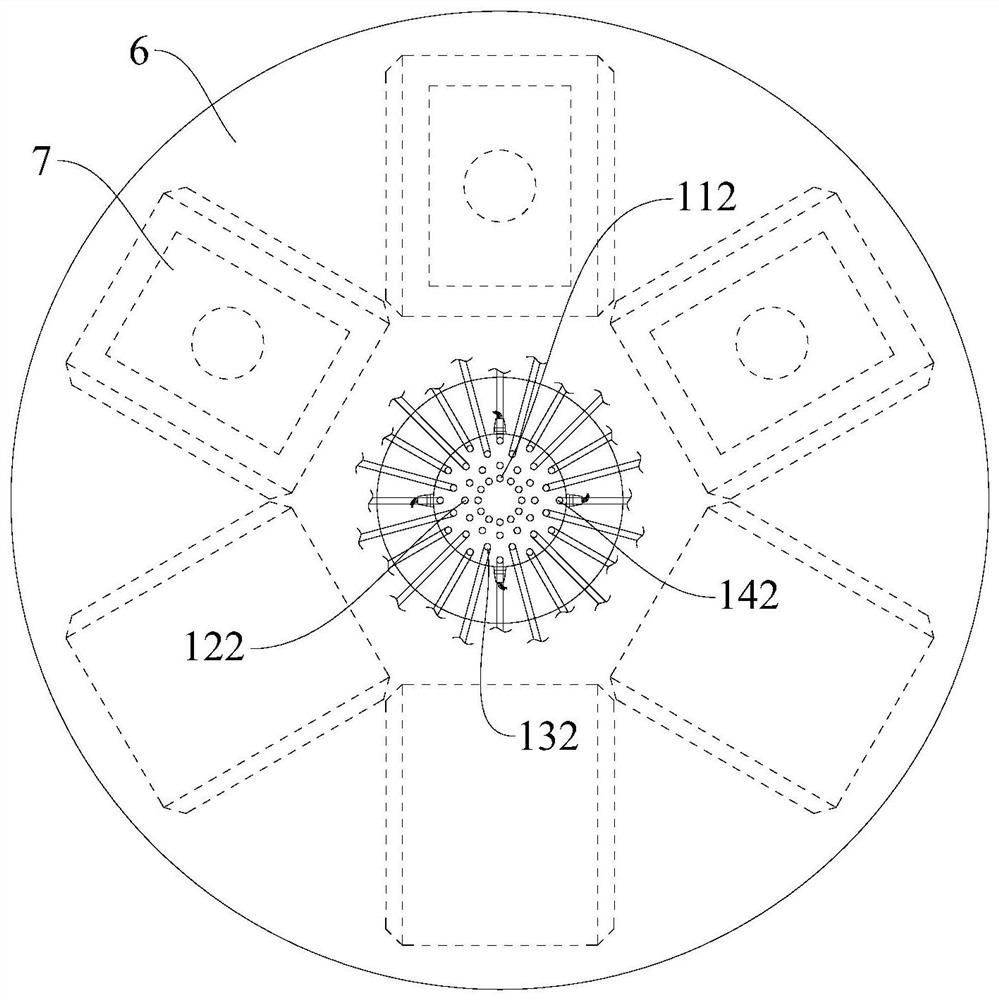

Cooling device of 1500 DEG C ultrahigh-temperature valve body

ActiveCN104455708AReduce direct washoutImprove reliabilityValve members for heating/coolingEngineeringWater cooling

A cooling device of a 1500 DEG C ultrahigh-temperature valve body comprises a medium inlet passage, a valve body middle port position, a valve cover and an end cap. The medium inlet passage and the valve body middle port position are arranged on the valve body and connected with each other, a high-temperature ceramic heat-insulating lining cooling structure is arranged on the medium inlet passage on the valve body, a valve body middle port is provided with a valve body middle port water cooling system, and requirements on safe and reliable running under a working condition of 1500 DEG C and 5.0 MPa are met. Part of heat of a high-temperature medium is absorbed by a midbody water cooling lower portion where pressure drop is formed, and pressure and temperature of the medium are further lowered; due to the structure, direct scouring of a valve seat sealing face by the high-temperature medium can be greatly reduced, service life of the valve is prolonged, and running reliability of the valve is improved.

Owner:LANZHOU HIGH PRESSURE VALVE

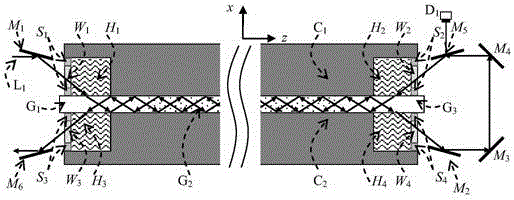

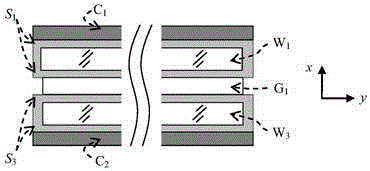

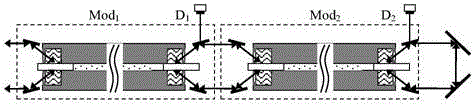

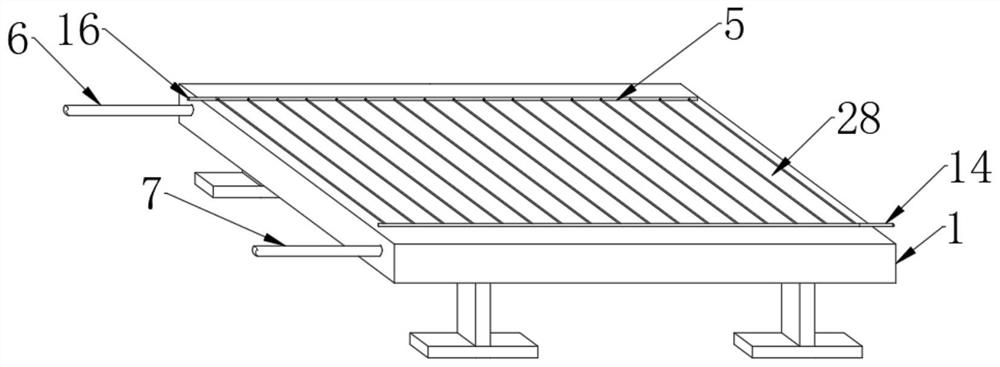

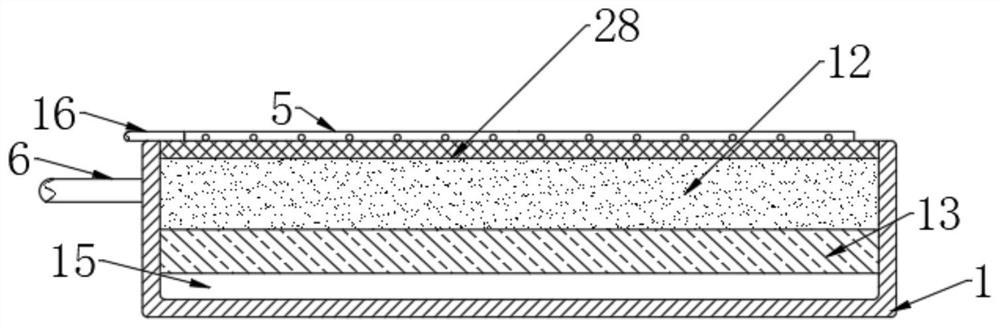

Slab laser module with wave-front distortion self-correction ability

ActiveCN106602391ADoes not change the number of total reflectionsIncrease powerExcitation process/apparatusComputer moduleLight beam

The invention provides a slab laser module with wave-front distortion self-correction ability through optimizing thermal management and optical path design. The slab laser module comprises a laser reflection device and a slab medium used as a gain medium. The upper and lower surfaces at the two ends of the slab medium are evanescent-membrane-free areas, and the middle part between the upper and lower surfaces is an evanescent membrane area. Incident laser L1 enters the inside of the slab medium from the evanescent-membrane-free area at one end of the slab medium, is transmitted along the length direction of the slab medium, and goes out from the evanescent-membrane-free area at the other end of the slab medium. The laser reflection device reflects the output incident laser L1 into the slab medium for second transmission, and the incident laser L1 goes out from the incidence end of first transmission. The constraint condition for the point-of-incidence position of second transmission of the incident laser L1 is that the wave-front distortion waveform generated when the incident laser L1 passes through the slab medium for the first time and the wave-front distortion waveform generated when the incident laser L1 passes through the slab medium for the second time are opposite. Thus, output laser featuring no wave-front distortion, high power and high beam quality is obtained.

Owner:NAVAL AERONAUTICAL & ASTRONAUTICAL UNIV PLA +1

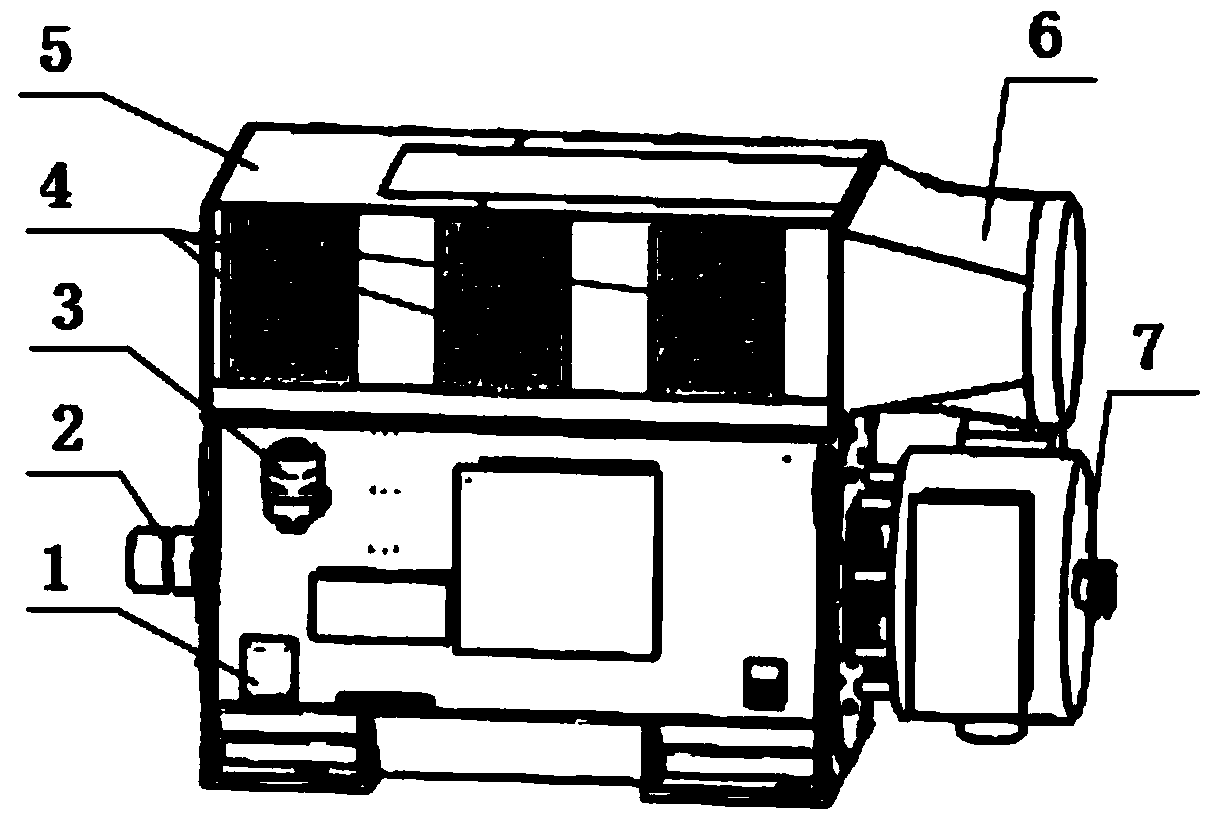

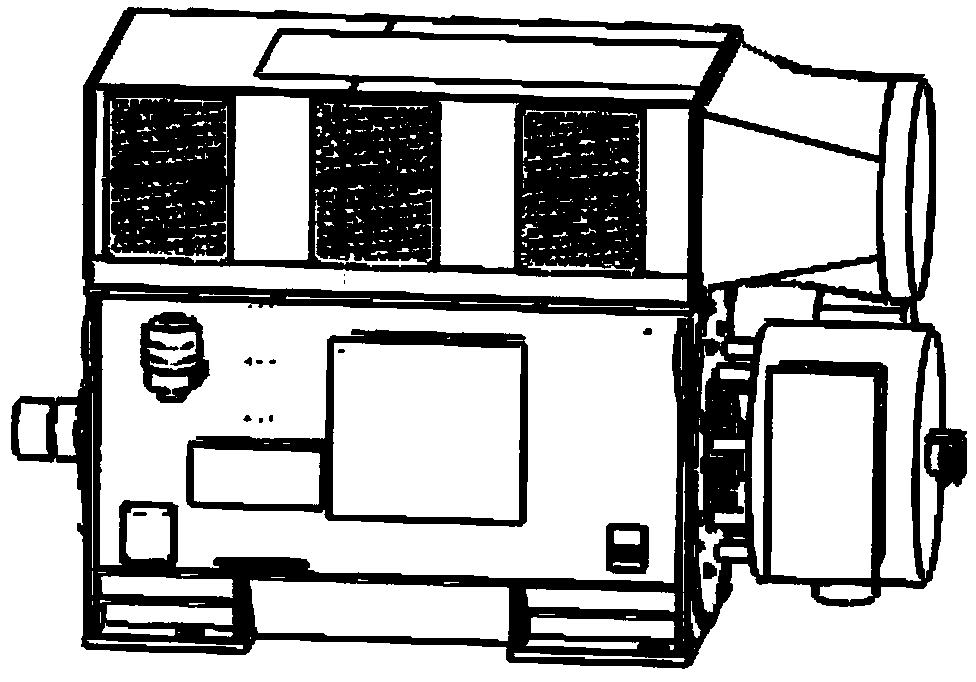

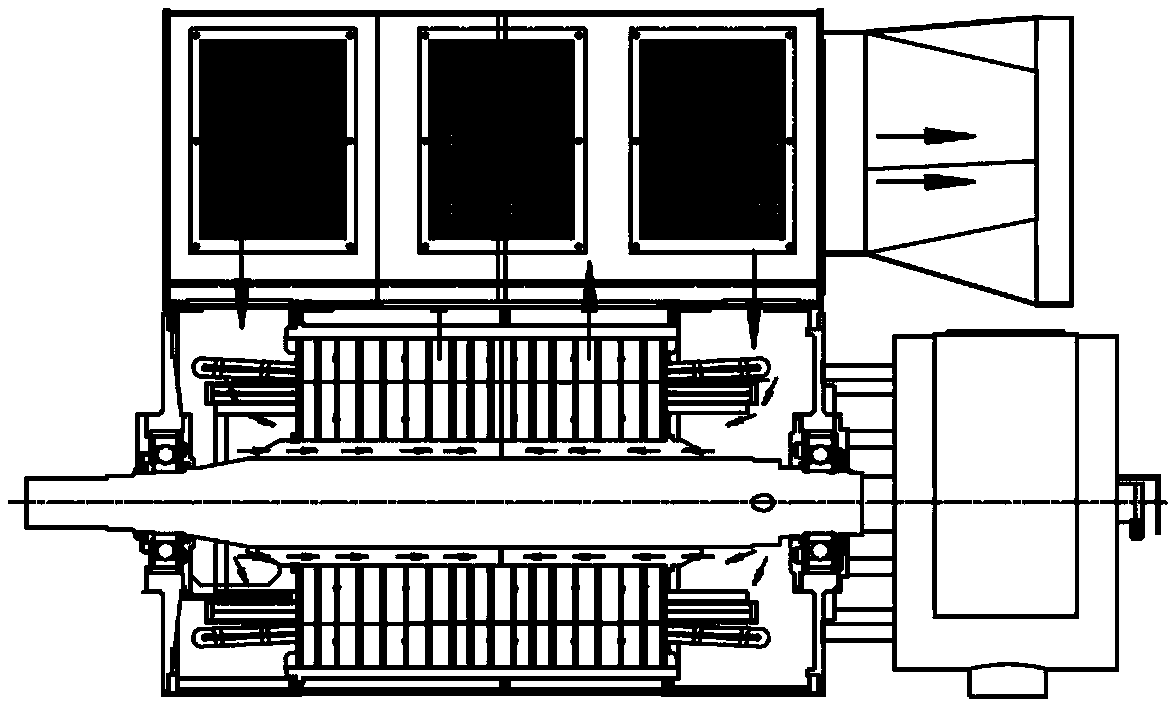

Wind-driven generator with novel cooling mode

PendingCN108683285AReduce the temperatureReduce heat lossAsynchronous induction motorsCooling/ventillation arrangementEnergy feedbackWind driven

A wind-driven generator with a novel cooling mode comprises a generator main structure and externally-mounted cooler. The cooling surface of the externally-mounted cooler is connected to the generatormain structure. The externally-mounted cooler includes a cooler box, an air inlet, an air outlet, and an air filtering device, wherein the cooler box is provided therein with a cooling air duct; theinlet of the cooling air duct is the air inlet; the air filtering device is disposed at the air inlet; and the other side of the outlet of cooling air duct is provided with the air outlet. The wind-driven generator can ventilate and cool the main body of the wind-driven generator by lower-temperature clean air in a self-ventilation way, has a heat dissipation effect, greatly reduces heat loss, reduces a failure rate caused by poor heat dissipation, and prolongs a service life so as to increase generated energy. The cooling scheme provided in the invention has good applicability, and can be applied to both an energy-feedback wind-driven generator and a squirrel cage asynchronous wind-driven generator.

Owner:ZHEJIANG WINDEY

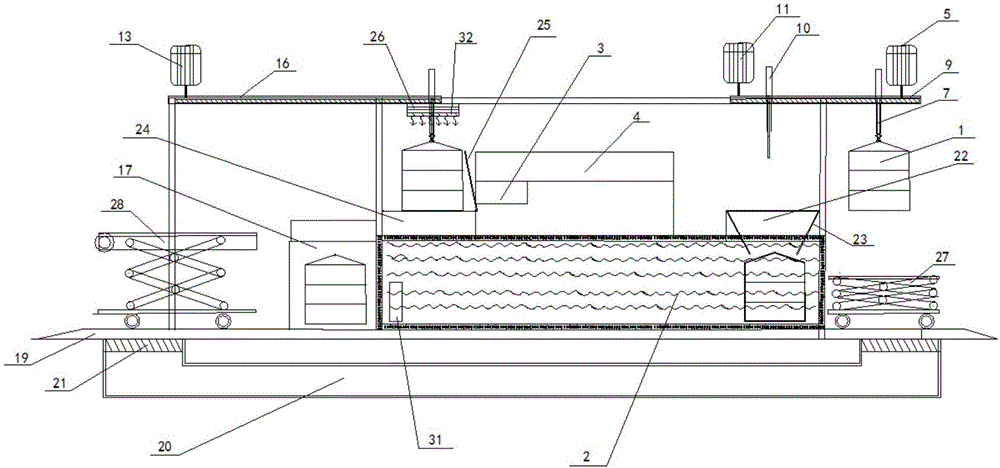

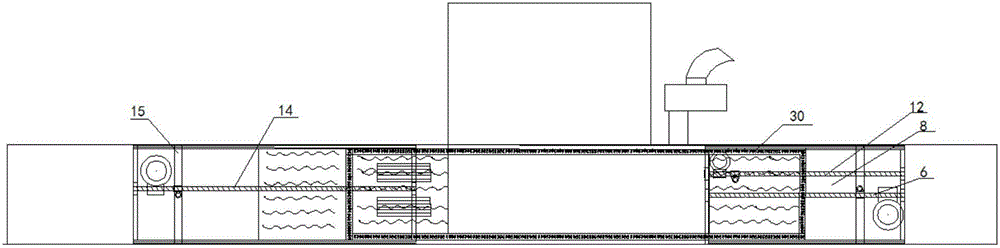

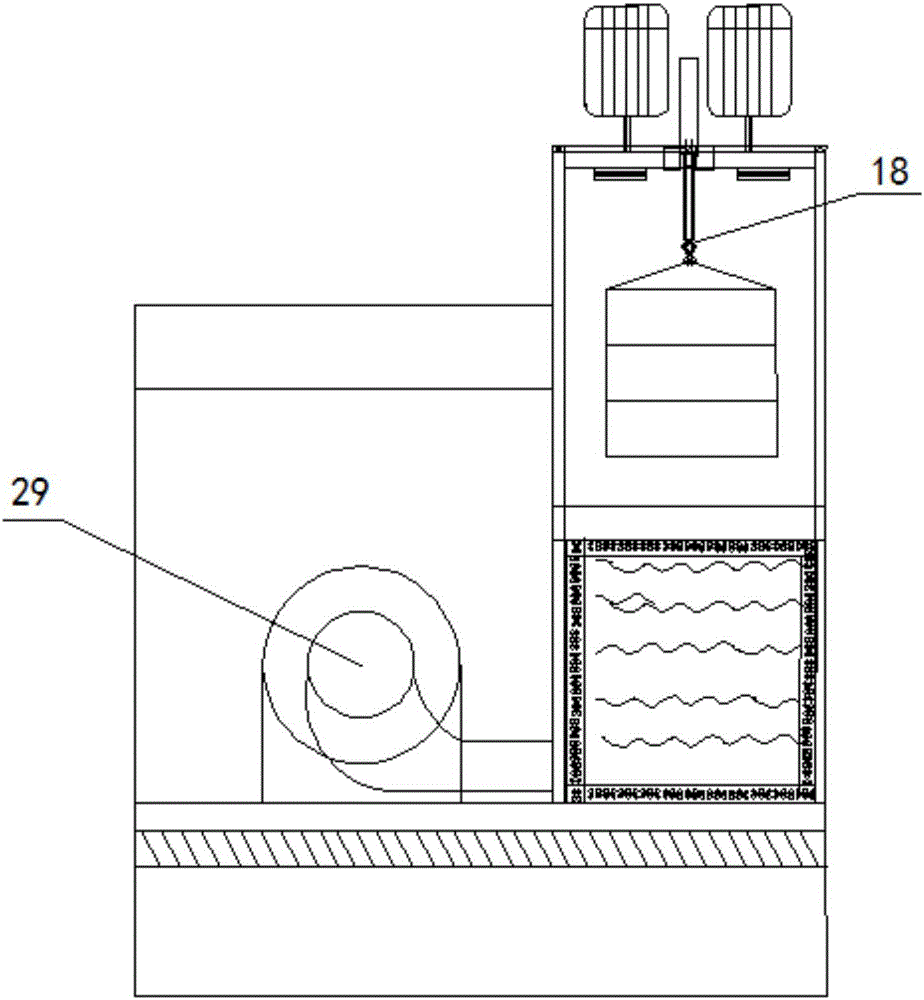

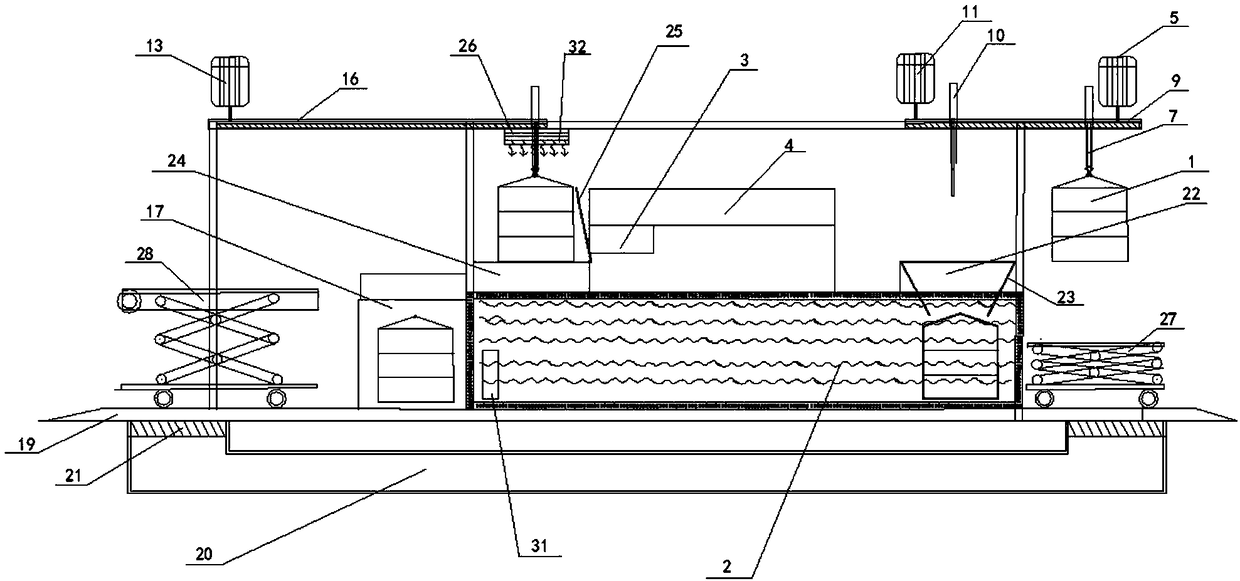

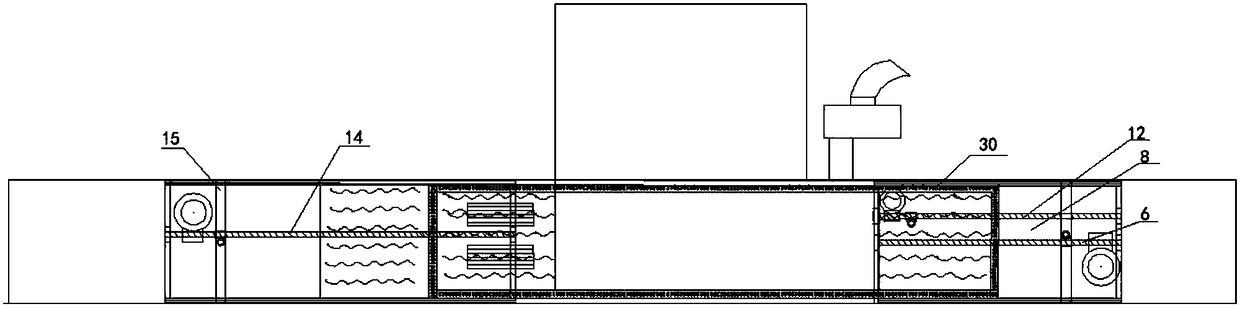

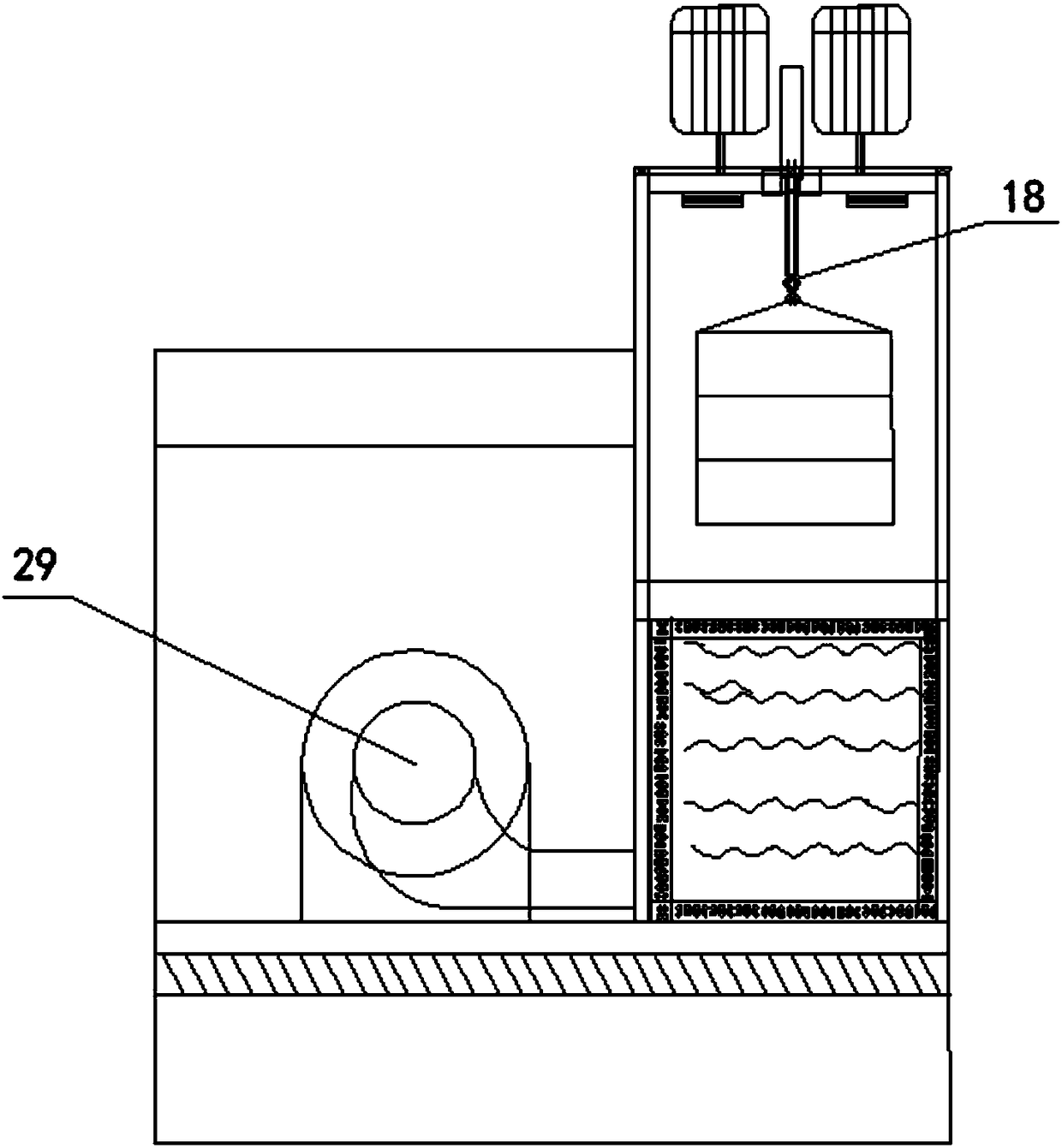

Marine seawater instant freezer

ActiveCN106091541AReduce consumptionMaintain qualityLighting and heating apparatusDomestic refrigeratorsEngineeringHanging basket

The invention discloses a marine seawater instant freezer used for instantly freezing marine products on a ship. The marine seawater instant freezer is arranged in a cabin or a refrigeratory of a cabin and provided with a freezing tank, a water tank, a refrigeration unit matched with the freezing tank, a conveying system and a hanging basket used for containing marine products. A liquid freezing medium used for freezing marine products is contained in the freezing tank. The hanging basket containing marine products is arranged in the freezing tank, the marine products is placed into the water tank after being cooled through the freezing medium, the surfaces of the marine products are instantly frozen, and therefore instant freezing of marine products is completed. Energy consumption can be greatly reduced, the purpose of instantly freezing marine products on sea better more rapidly is achieved, and the quality and delicious taste of the marine products can be kept.

Owner:辽宁金丰粮食机械制造有限公司

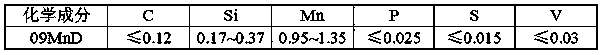

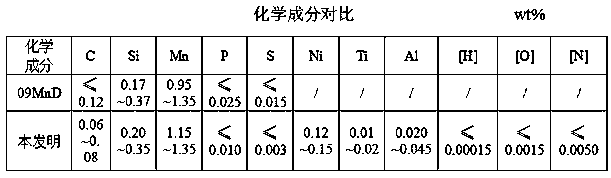

Ultrahigh-impact-toughness high-purity-degree steel for low temperature pressure vessel and production method thereof

ActiveCN108707828AImprove low temperature impact toughnessThe overall mechanical properties are stableProcess efficiency improvementDeoxidizationCrystallite

The invention discloses ultrahigh-impact-toughness high-purity-degree steel for a low temperature pressure vessel. The ultrahigh-impact-toughness high-purity-degree steel comprises the chemical components of, by mass, 0.06-0.08% of C, 0.20-0.35% of Si, 1.15-1.35% of Mn, 0.01-0.02% of Ti, 0.12-0.15% of Ni, 0.020-0.045% of Al, 0-0.010% of P, 0-0.003% of S, 0-0.0015% of [O], 0-0.0050% of [N], 0-0.00015% of [H] and the balance Fe. In this way, according to the ultrahigh-impact-toughness high-purity-degree steel for the low temperature pressure vessel and a production method thereof, the content ofthe C is decreased through precise control, strong deoxidization and crystalline grain refining are conducted through the Al, alloying is conducted through the Ni and the Ti, thus, compared with 09MnD steel of Q / TDGG 0040-2004, the ultrahigh-impact-toughness high-purity-degree steel is suitable for the lower medium temperature which is from -50 DEG C to -55 DEG C, and has higher low-temperature impact toughness, and the overall mechanical property of the ultrahigh-impact-toughness high-purity-degree steel is more stable.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

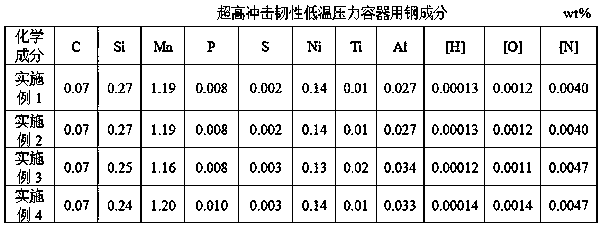

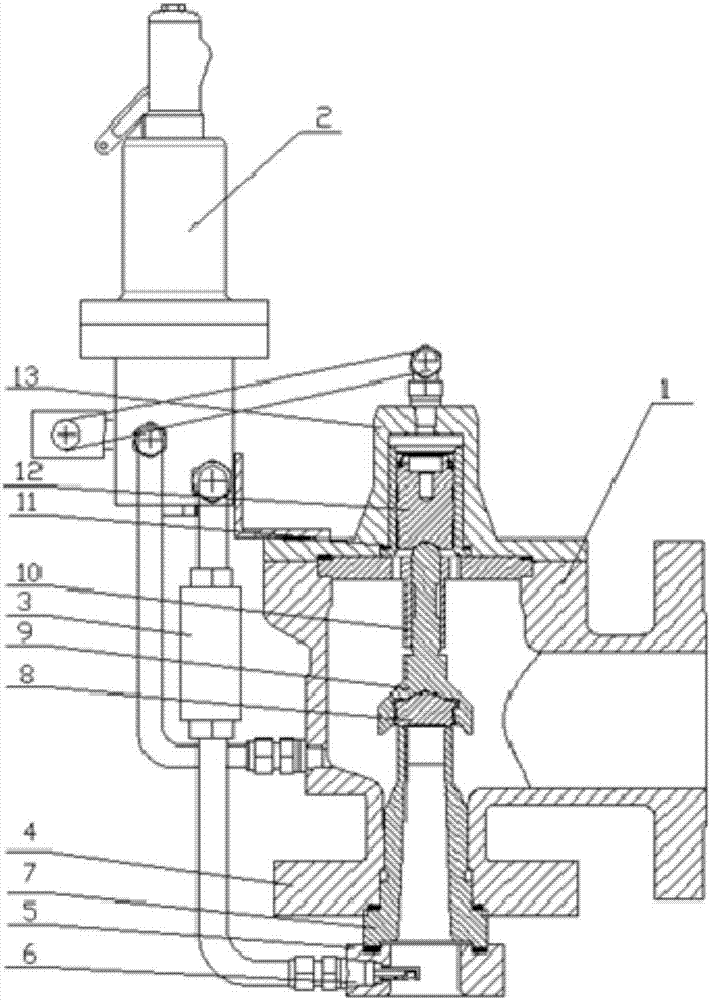

Pilot operated safety valve for high-temperature working conditions

ActiveCN107300027AAir chamber pressure dropReduce overpressureSpindle sealingsOperating means/releasing devices for valvesEngineeringSafety valve

The invention relates to the technical field of valve design, and specifically discloses a pilot operated safety valve for high-temperature working conditions. The pilot operated safety valve for the high-temperature working conditions comprises a main valve, a pilot valve and a heat exchange device, wherein the pilot valve is connected with one end of the heat exchange device, a gas chamber of the main valve and the valve body cavity of the main valve through pressure pipes respectively, and the other end of the heat exchange device is connected with a dipper-shaped pipe arranged at the main valve through a pressure pipe. According to the pilot operated safety valve for the high-temperature working conditions, an inlet seal structure is designed in the pilot valve so as to prevent a medium from entering the gas chamber of the main valve through the pilot valve, and an outlet seal structure is designed in the pilot valve so as to prevent a medium in the gas chamber of the main valve from entering the outlet of the pilot valve; in addition, a metal hard seal structure is adopted in the sealing surface of the main valve, a valve flap of the main valve is mounted on a recoil plate and can swing slightly, and when the main valve is closed, the valve flap of the main valve can be automatically calibrated so as to improve the sealing performance of the main valve while the problem of high-temperature seal of the main valve is solved.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

Intelligent pressure transmitter

PendingCN108072484AAvoid damageSolve the problem of complex and not simpleFluid pressure measurementWater vaporEngineering

The invention discloses an intelligent pressure transmitter. The intelligent pressure transmitter comprises a device body and a heat preservation device which is arranged at the lower end of the device body, the heat preservation device is arranged in the device body through bolts, a line hole is formed in the front of the top of the device body and embedded in the device body, side covers are arranged on the left side and the right side of the device body and arranged on the device body through bolts, a support structure is arranged in the middle of the device body, and the support structureis welded to the device body. According to the intelligent pressure transmitter, a fixing ring is arranged on the outer side of the line hole, by means of the fixing ring, a power line interface is isolated from the internal structure, and rainwater or steam can be prevented from entering the device, so that an internal circuit is damaged; in addition, the problem that parts in the device make contact with air for a long time, and oxidation is caused can be prevented, and the problems that for existing design, a power line export end is poor in protective measures, and the internal circuit cannot be well protected are solved.

Owner:天津青年志科技有限公司

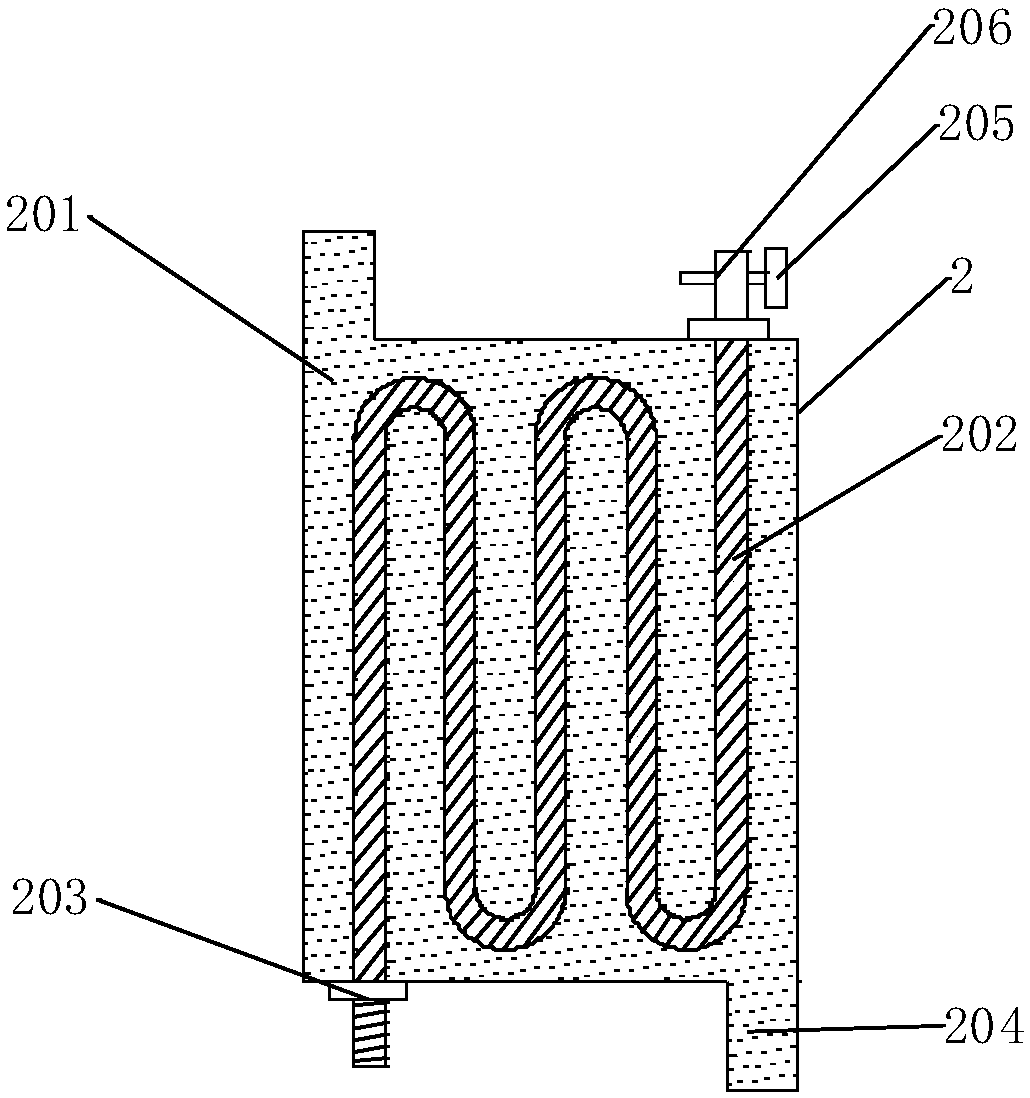

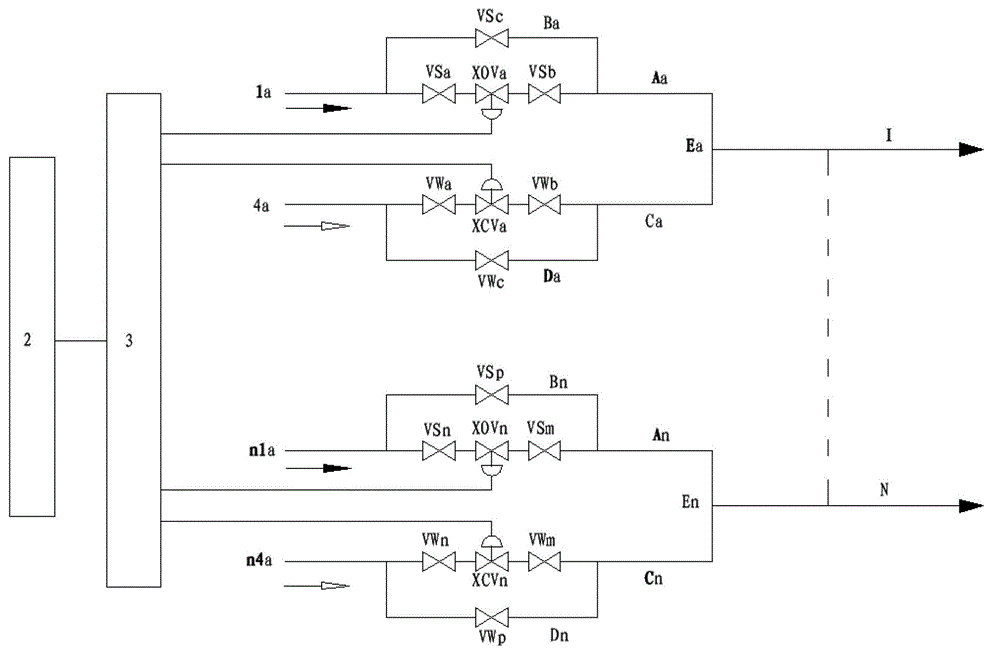

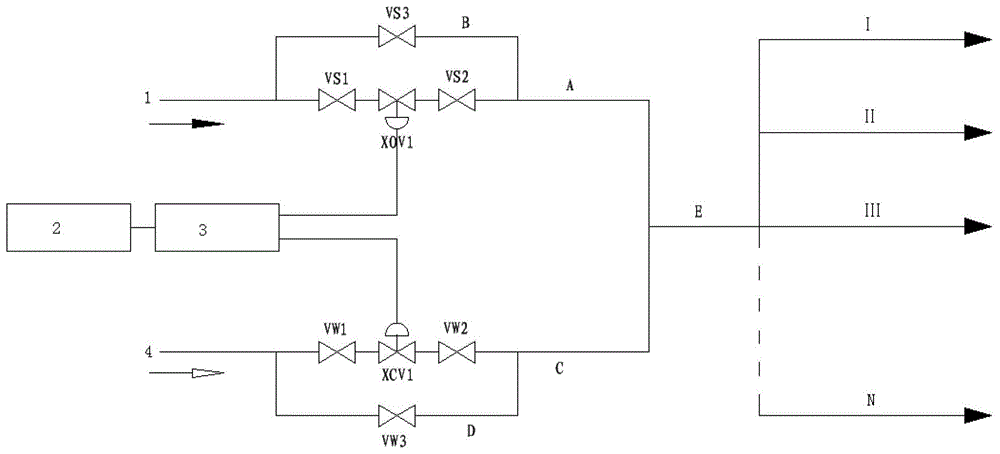

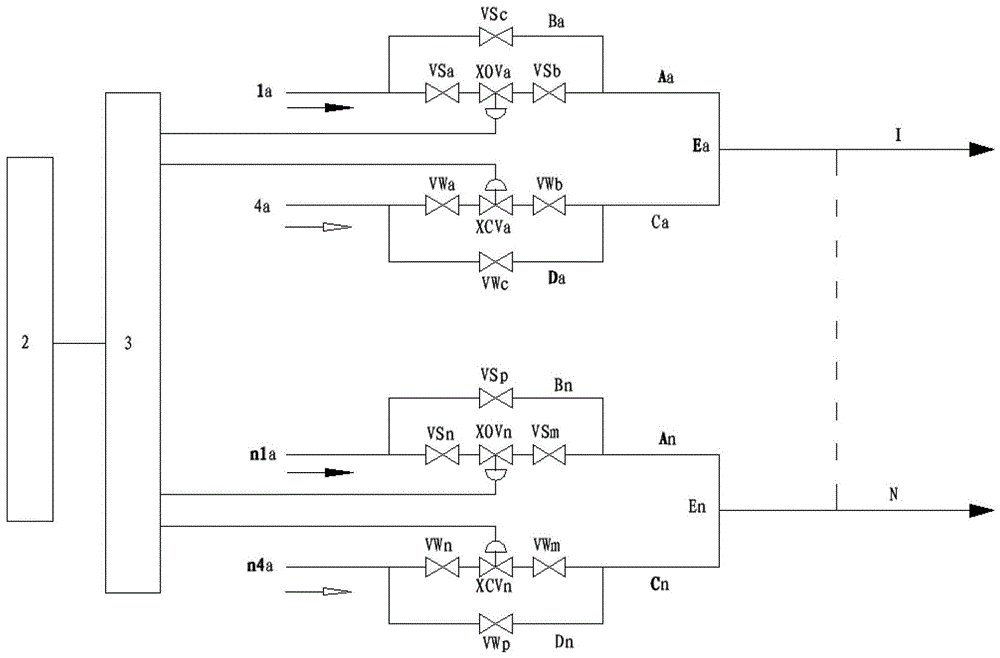

Self-control type energy-efficient heat tracing system

ActiveCN104019360ARealize intelligent controlReduce wastePipeline systemsTransport systemControl system

The invention discloses a self-control type energy-efficient heat tracing system and belongs to the fields of petroleum refining, petrochemical engineering and petroleum storage and transport. According to the heat tracing system, steam serves as a heat tracing medium. A control system is arranged in a steam heat tracing system. The self-control type energy-efficient heat tracing system comprises the steam heat tracing system and a blowing and sweeping air system. The blowing and sweeping air system and the steam heat tracing system are interlocked through a control unit when a petroleum refining and chemical engineering device or a petroleum storage and transport system is operated, so that servo operation of use / cutting of the steam heat tracing system and the operation state / shut-down state of the petroleum refining and chemical engineering device or the petroleum storage and transport system is achieved. An existing continuous inflow steam heat tracing mode is improved into a self-control intermittent feeding type steam heat tracing mode, system operation is good, intelligent control over the steam heat tracing system in the operation state of the petroleum refining and chemical engineering device or the petroleum storage and transport system is achieved, steam is reasonably and intermittently used, it is guaranteed that the temperature of the medium is lower than the temperature of the heat tracing steam, and waste of energy and consumption of water resources are effectively reduced.

Owner:PETROCHINA CO LTD

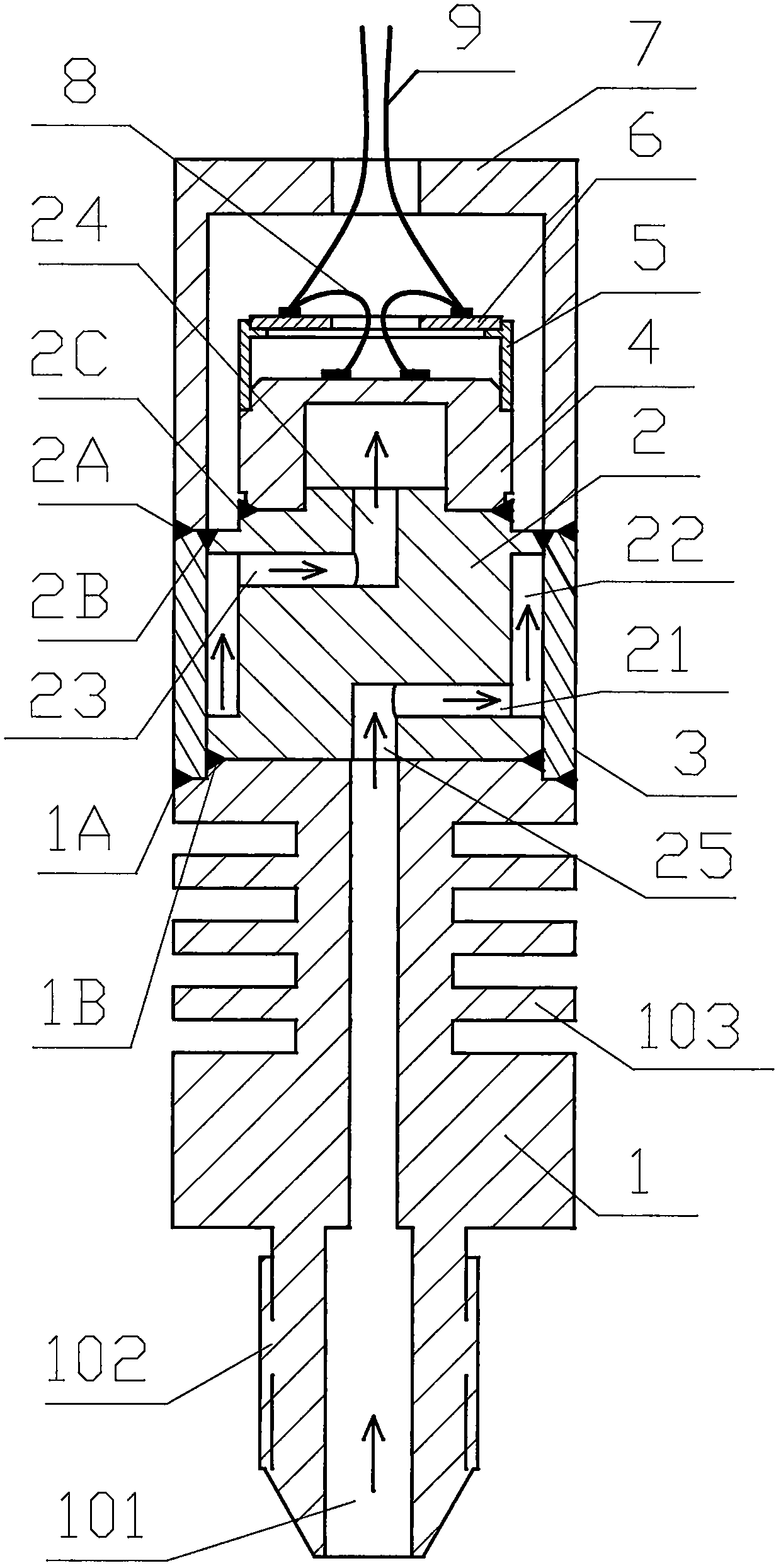

Ultrahigh temperature pressure sensor and manufacturing method thereof

PendingCN107631833AHigh measurement accuracyImprove stabilityFluid pressure measurement by electric/magnetic elementsCentral pressureEngineering

The present invention discloses an ultrahigh temperature pressure sensor and a manufacturing method thereof. The ultrahigh temperature pressure sensor is composed of a pressure leading member with radiating fins, a pressure guiding member, a radiating ring and a shell, and is characterized in that the pressure guiding member is a cylinder of which the upper central position is equipped with an upper central pressure leading hole, the lower central position is equipped with a lower central pressure leading hole that is not communicated with the upper central pressure leading hole, the middle periphery is equipped with a pressure guiding groove, the lower part is equipped with a lower pressure guiding hole communicated with the lower central pressure leading hole and the pressure guiding groove, and the upper part is equipped with an upper pressure guiding hole communicated with the upper central pressure leading hole and the pressure guiding groove. The two levels radiating structures of the radiating fins and the radiating ring are adopted, so that the temperature of a medium is overall reduced to about 25% of an original temperature, and accordingly, a sputtering thin film pressure core body suitable for the high temperature can measure the pressure of a high temperature medium not more than 600 DEG C very well. Meanwhile, the ultrahigh temperature pressure sensor retains theadvantages of a sputtering thin film pressure sensor of being small in size, high in measurement precision and good in stability, etc., and can be applied to the ultrahigh temperature medium pressuremeasurement field very well.

Owner:SONGNUOMENG TECH CO LTD

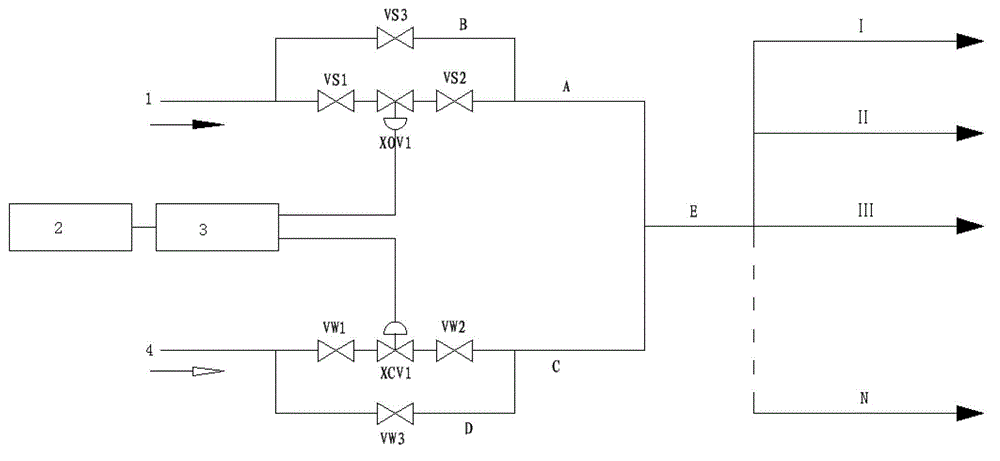

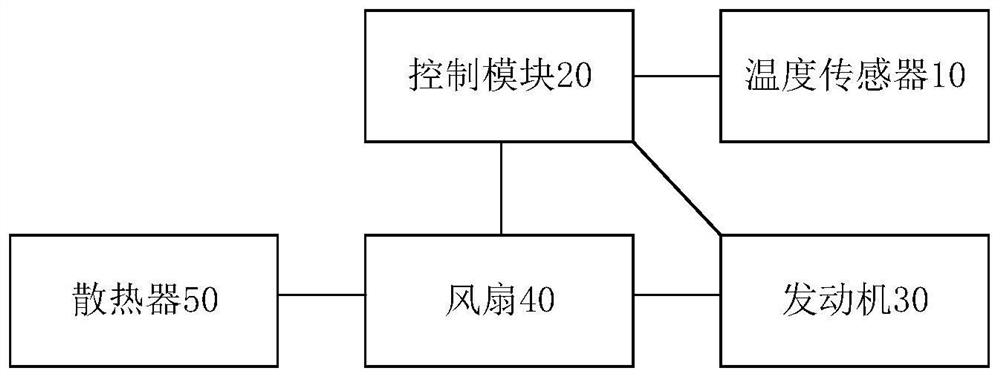

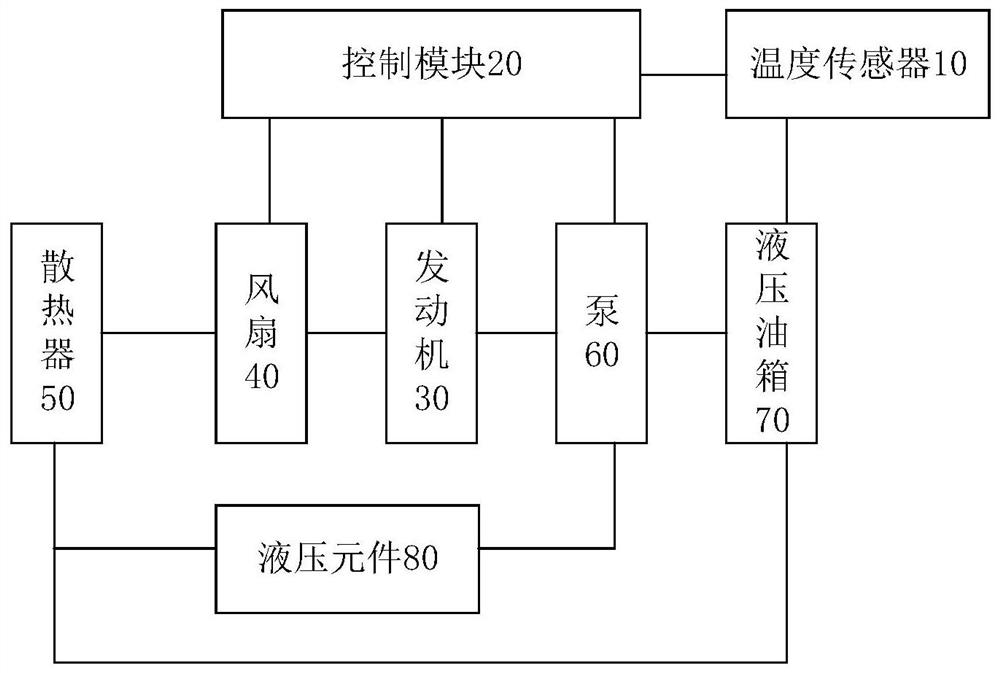

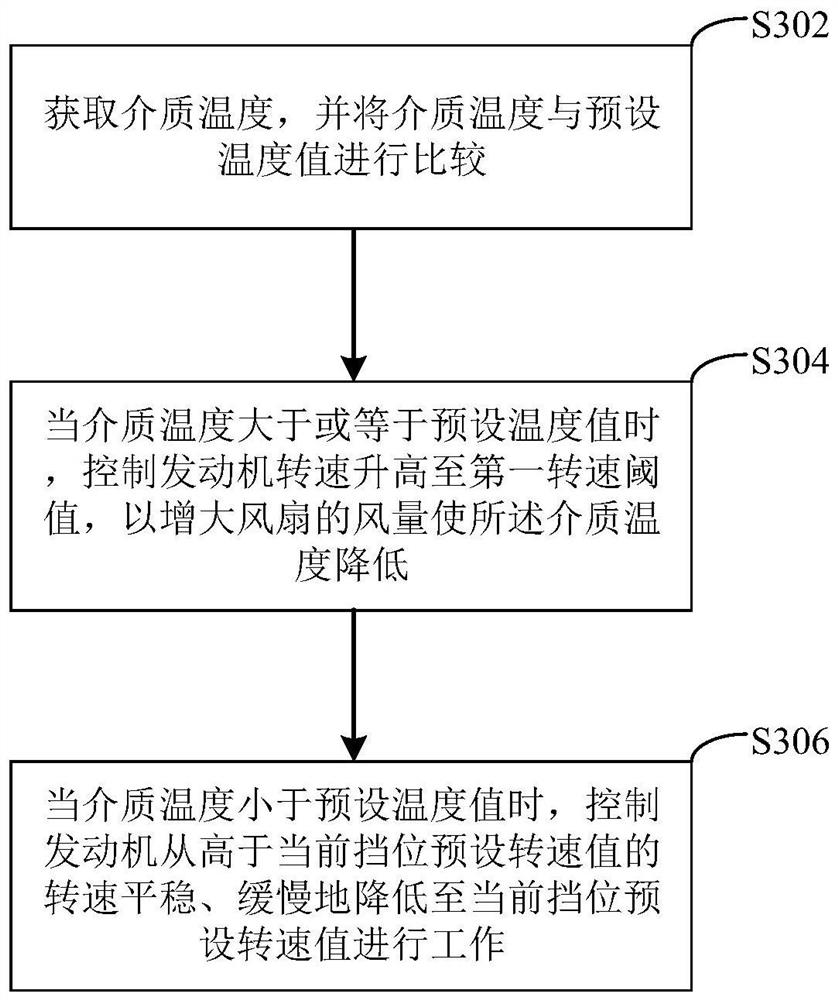

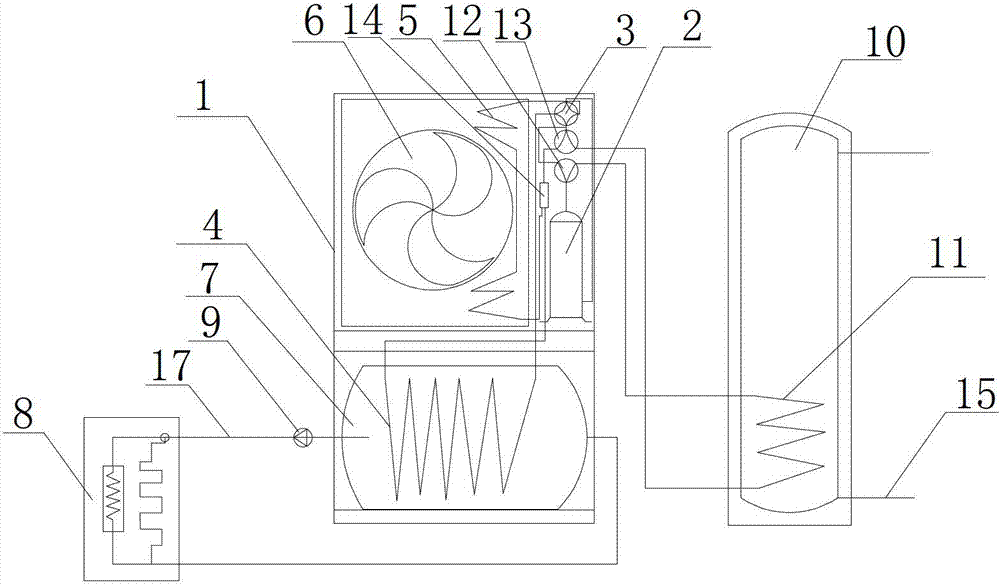

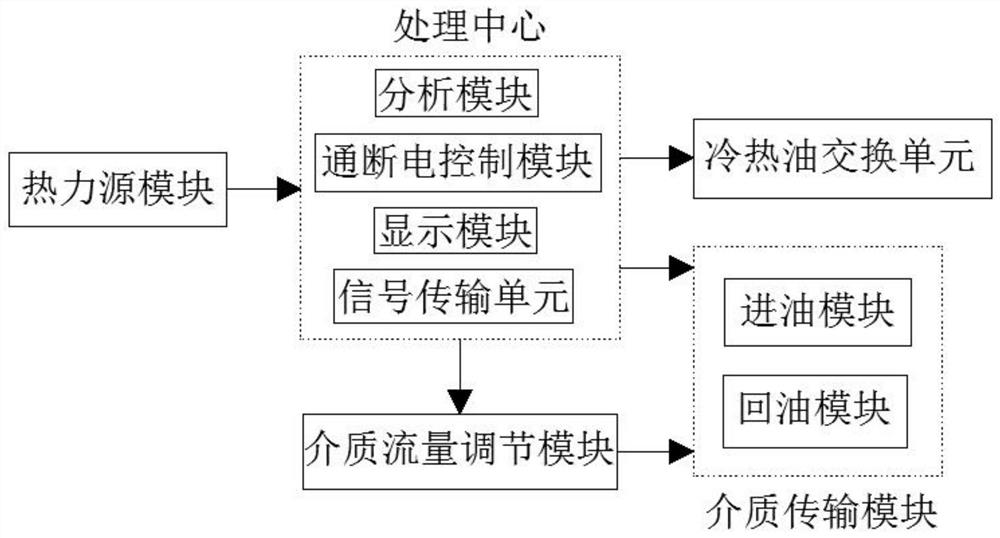

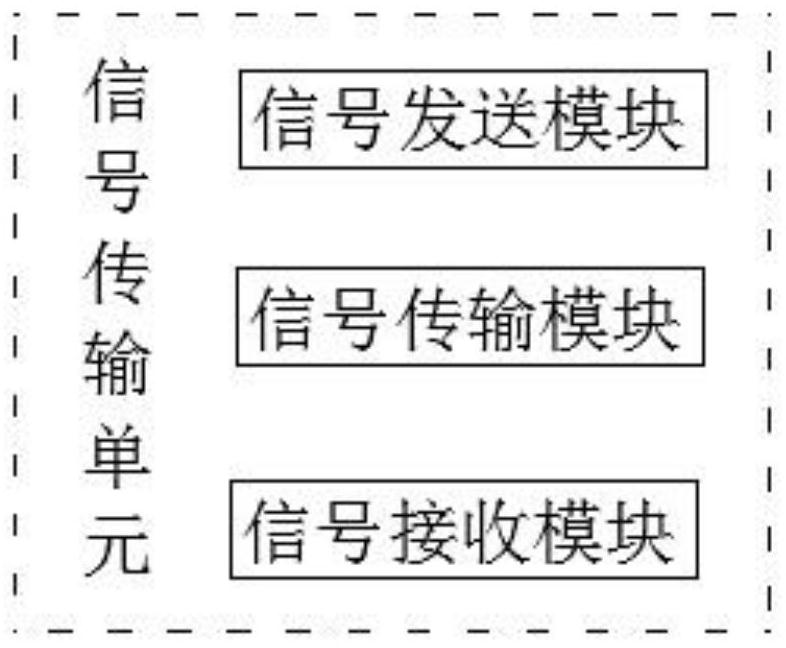

Medium temperature control system and method and engineering vehicle

ActiveCN112160828AReduce medium temperatureLow costCoolant flow controlMachines/enginesTemperature controlAir volume

The invention provides a medium temperature control system and method and an engineering vehicle. The medium temperature control system comprises a temperature sensor, a control module, an engine, a fan and a radiator; the temperature sensor is used for acquiring medium temperature; the control module is used for controlling engine speed and fan air volume according to the medium temperature; thefan is used for providing air volume for the radiator so that the radiator can reduce the medium temperature; the control module is further used for comparing the medium temperature with a preset temperature value, and when the medium temperature is larger than or equal to the preset temperature value, the engine speed is controlled to rise to a first rotating speed threshold value; when the medium temperature is smaller than the preset temperature value, and an engine is controlled to work at the preset rotating speed value of a current gear; and the preset rotating speed value of the currentgear is smaller than the first rotating speed threshold value. According to the medium temperature control system and the method and the engineering vehicle, and the equipment cost and the failure rate can be reduced while the medium temperature is reduced.

Owner:SANY HEAVY MACHINERY

Microwave ceramic dielectric for high-frequency ceramic capacitors and preparation method thereof

The invention discloses microwave ceramic dielectric for high-frequency ceramic capacitors and a preparation method thereof. The microwave ceramic dielectric comprises Ba6-3xNd8+2xTi18O54, wherein x=1 / 2-2 / 3, and y=1 / 5-2 / 5; component materials include BaCO3, Nd2O3 and TiO2, as well as the additive Bi2O3. The preparation method includes the steps of mixing the materials according to a formula, usingZrO2 spheres to perform ball milling in deionized water, drying at 120-130 DEG C, and screening under 40 mesh; pre-sintering at 900-1100 DEG C, and holding the temperature for 2 hours; performing secondary ball milling, drying, granulating, and pressing under 80-90 MPa to shape; sintering at 1150-1250 DEG C, holding the temperature for 4 hours, and cooling for 10 hours and longer. The microwave ceramic dielectric has excellent dielectric properties, the formula is simple, the microwave ceramic dielectric has good process stability, and particularly dielectric loss is not sensitive to pre-sintering temperature and sintering temperature. The microwave ceramic dielectric is widely applicable to the manufacture of microwave devices, such as dielectric resonators and filters, and may meet thedemands for material dielectrics in system applications, such as mobile communication, satellite communication, navigation and positioning, and radar.

Owner:JIANGSU TIANZIGE NEW MATERIAL TECH CO LTD

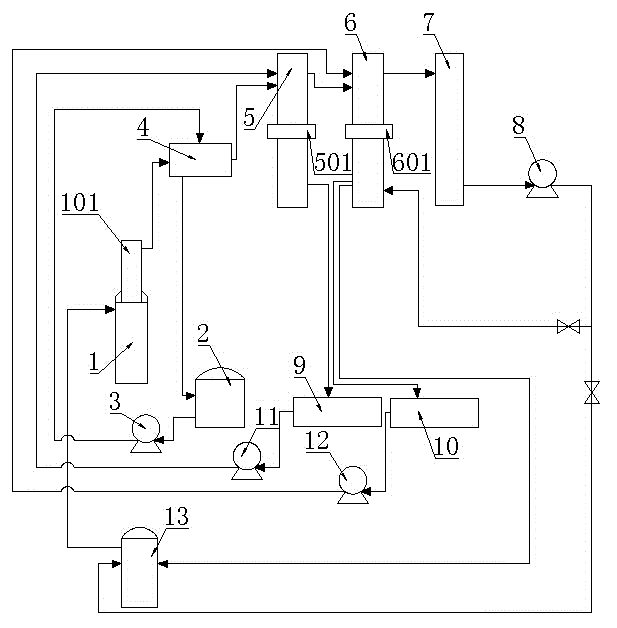

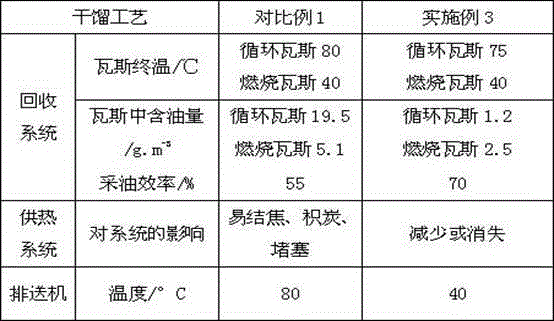

Full-negative-pressure recovery process of dry distillation furnace generation gas in oil shale dry distillation oil refining and system thereof

InactiveCN104531196AReduce the amount of oilImprove oil production efficiencyDirect heating destructive distillationLiquid hydrocarbon mixture productionHeat carrierHeating furnace

Provided are a full-negative-pressure recovery process of dry distillation furnace generation gas in oil shale dry distillation oil refining and a system thereof. The recovery system comprises a dry distillation furnace, a mud collecting tank, a mud collecting pump, a collecting pipe, washing saturation towers, an indirect cooling tower, a gas exhaust-feeding machine, a washing pool, a washing pump and a heating furnace. According to the recovery process, generation gas generated by the dry distillation furnace in oil shale dry distillation oil refining is pumped to the collecting pipe, a washing saturation tower I and a washing saturation tower II for spraying washing through the gas exhaust-feeding machine, the gas is conveyed into the indirect cooling tower, after heat exchanging in the direct cooling tower, one part of the gas is conveyed into the heating furnace by the gas exhaust-feeding machine for heating the heating furnace, the other part of the gas is used as circulation gas to be conveyed to the bottom of the washing saturation tower II, and after heat exchanging, the gas enters the heat storage type heating furnace for continuous heat exchanging and is used as a heat carrier to be conveyed to the dry distillation furnace. The process and the system have the advantages that the process is simple, whole system heat is fully used, energy loss is low, water using amount is small, and oil productivity can be improved.

Owner:BEIPIAO BEITA OIL SHALE INTEGRATED DEV UTILIZATION CO LTD

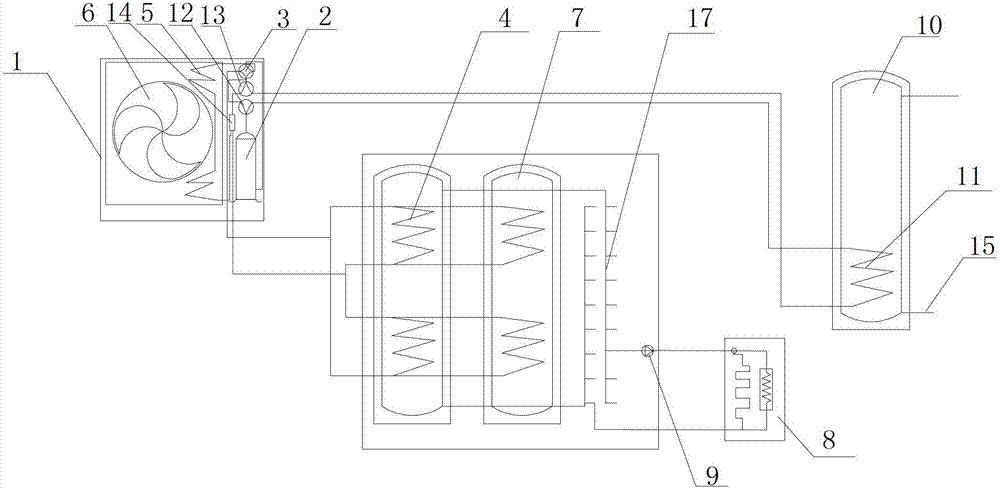

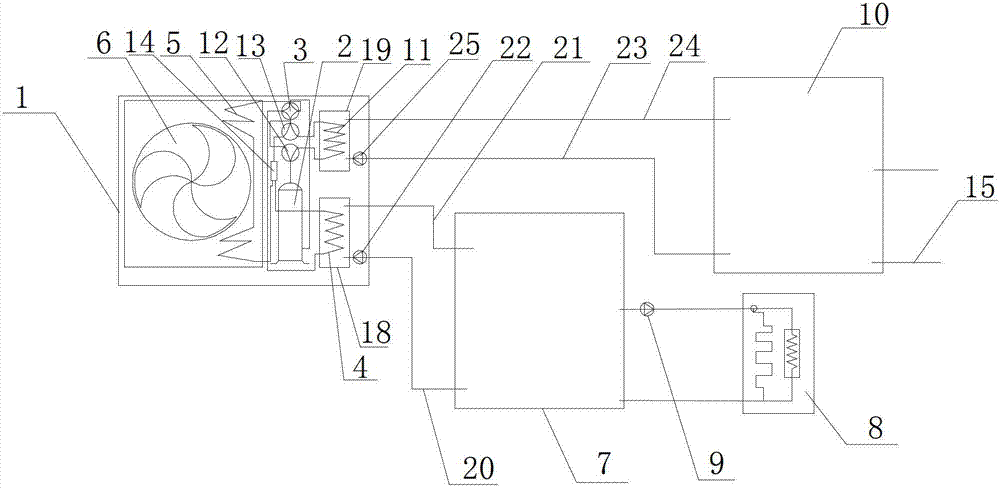

Cold and heat accumulation type hot-water air conditioner

InactiveCN102889654ATake advantage ofReduce negative impactEnergy recovery in ventilation and heatingLighting and heating apparatusFour-way valveRecuperator

The invention discloses a cold and heat accumulation type hot-water air conditioner which comprises a main engine box and a circulation loop connected with a compressor, a four-way valve, an air-conditioning heat exchanger and an outdoor heat exchanger, and also comprises a cold and heat accumulation type insulation box, wherein the cold and heat accumulation type insulation box and the air-conditioning heat exchanger form a first heat exchange system. The air conditioner also comprises a hot-water insulation box, wherein an outlet end of the compressor is connected with a hot-water heat exchanger; the hot-water heat exchanger and the hot-water insulation box form a second heat exchange system; two ends of the hot-water heat exchanger are respectively connected with a first three-way valve and a second three-way valve; and an outlet end of the second three-way valve is connected with a multi-flow-path throttling device. According to the cold and heat accumulation type hot-water air conditioner, multiple different operating modes can be realized, the energy can be fully utilized, the energy consumption is reduced, and the heat output is reduced.

Owner:湖南全益能源科技有限公司

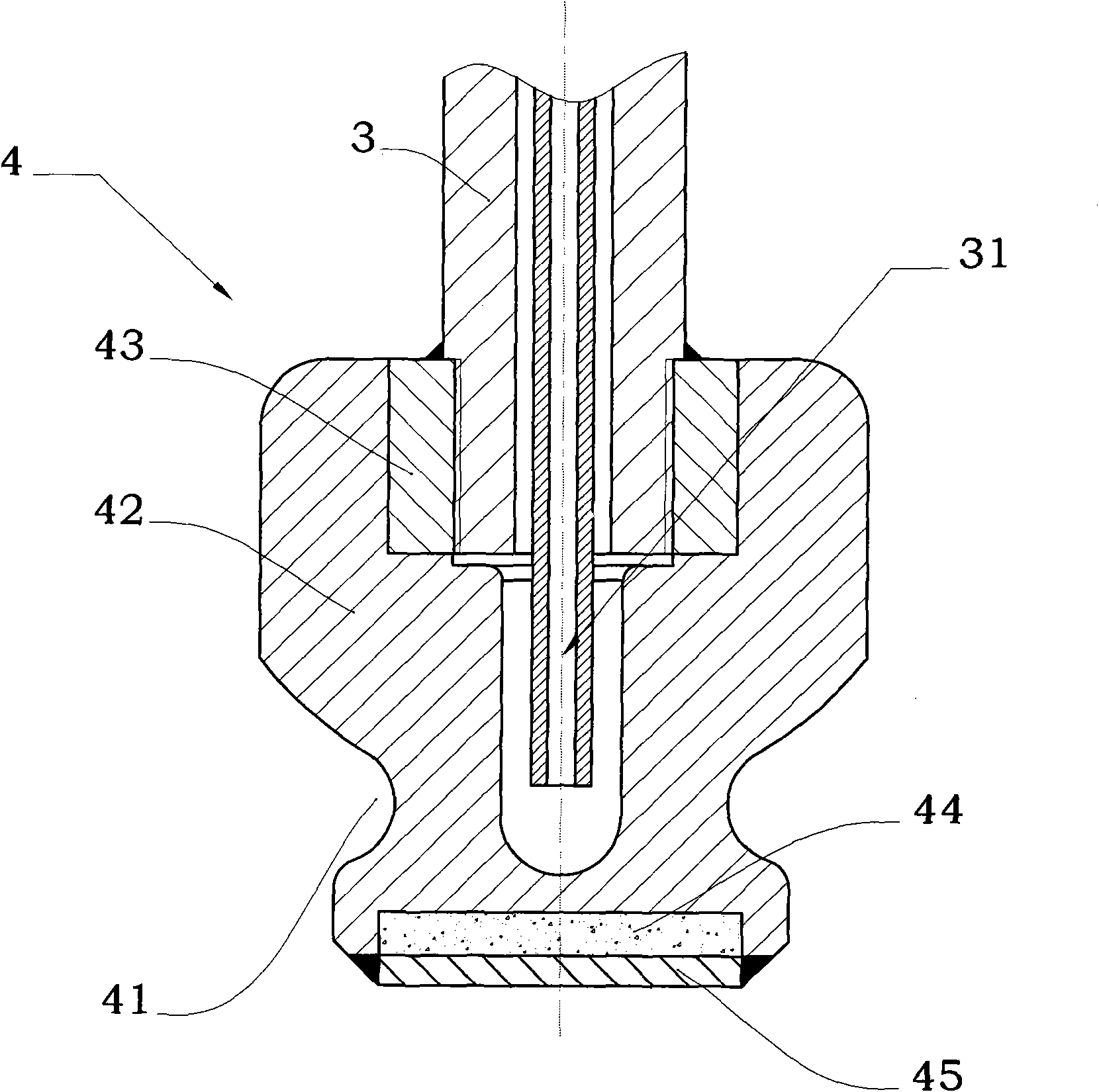

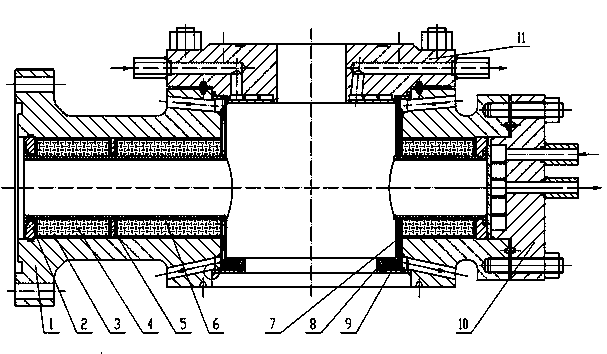

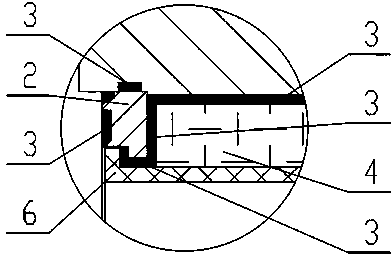

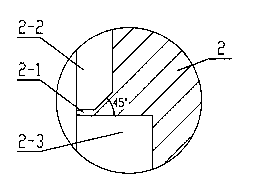

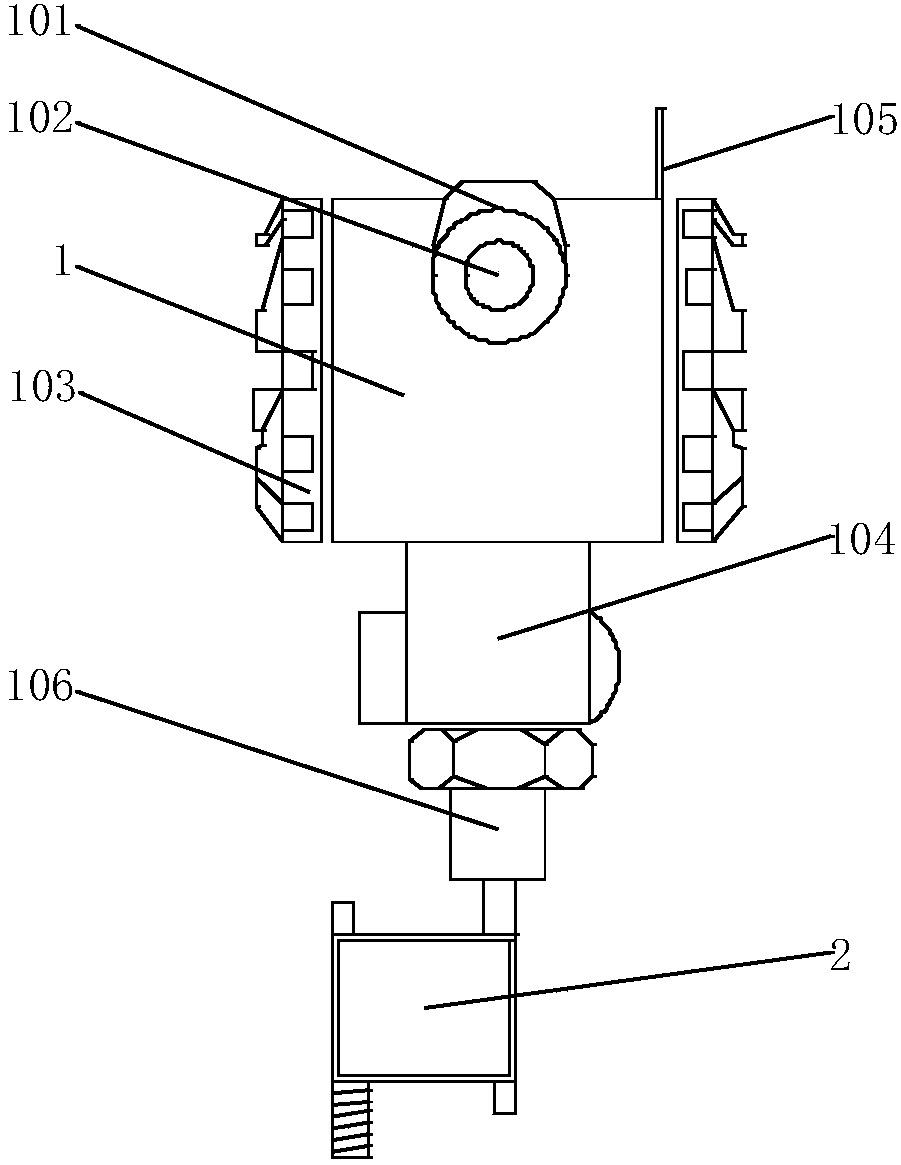

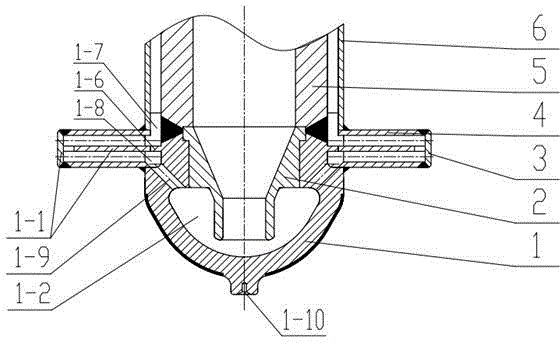

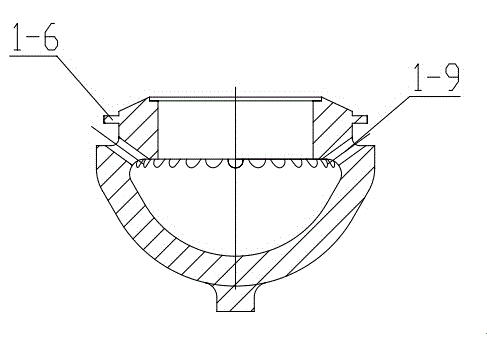

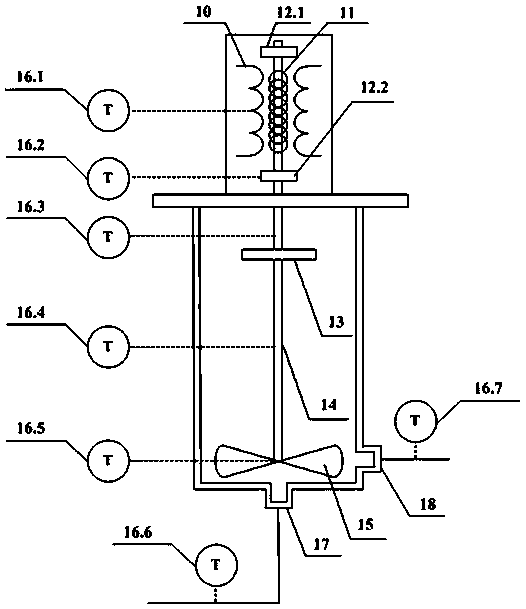

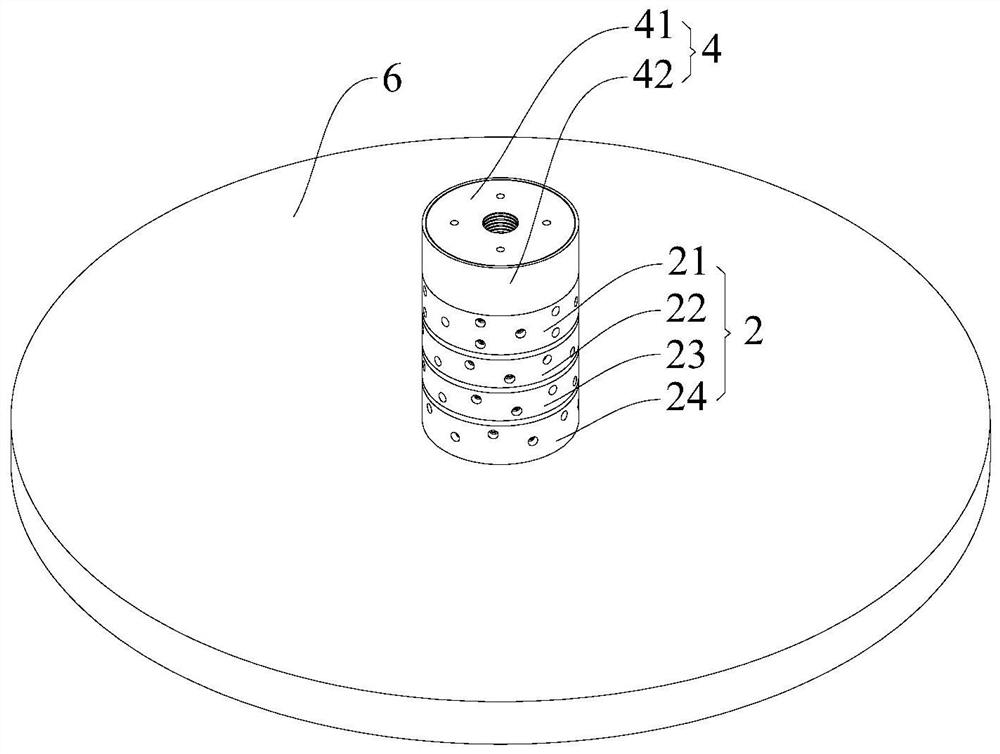

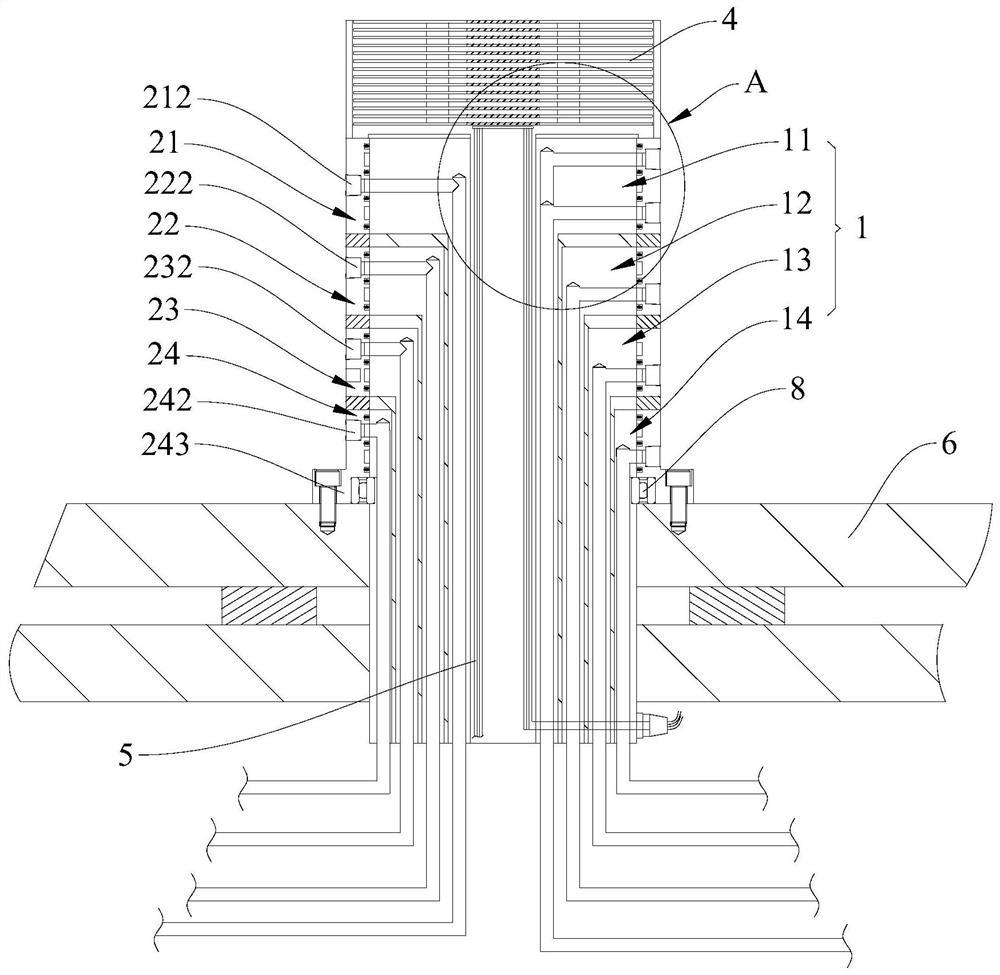

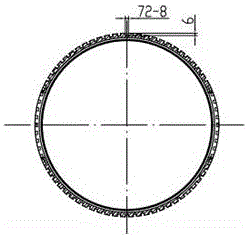

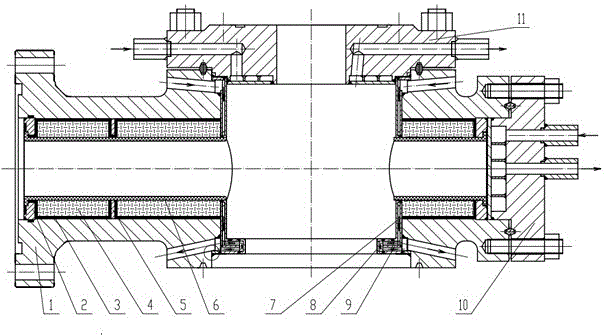

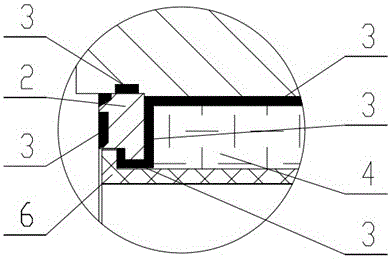

Water cooling valve clack structure of 1500 DEG C ultrahigh-temperature valve

ActiveCN104455707AGuaranteed uptimeReduce direct washoutValve members for heating/coolingEngineeringVALVE PORT

A water cooling valve clack structure of a 1500 DEG C ultrahigh-temperature valve comprises a valve rod and a valve clack body. The upper end of the valve clack body is connected with a convex lug through a flange, a runner inlet end in the convex lug is communicated with a concave pit in the valve clack body while a runner outlet end in the same is connected with a recycling end of an externally-connected cooling system, the concave pit is communicated with an inlet end of the externally-connected cooling system through a water cooling nozzle, the convex lug comprises an inner ring portion and an outer ring portion which are hermetically assembled into a whole, grooves are uniformly distributed in the outer circumferential face of the inner ring portion, holes in up-down arrangement are processed in the grooves, and upper-layer holes and lower-layer holes are formed in the whole periphery and all communicated with the inner surface of the inner ring portion. Due to the structure, direct scouring of a valve seat sealing face by a high-temperature medium is greatly reduced, and service life of the valve is prolonged, and running reliability of the valve is improved; heat transfer and thermodynamic calculation shows that a valve clack can run safely and reliably under a working condition of 1500 DEG C.

Owner:LANZHOU HIGH PRESSURE VALVE

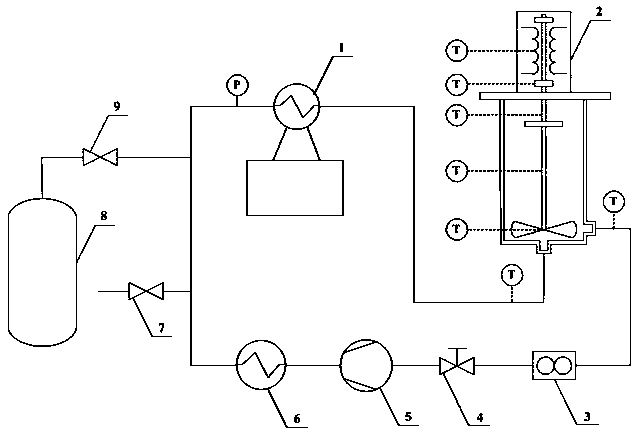

Rotor temperature measurement simulated system and method for low-temperature centrifugal type fluid machine

ActiveCN110095206AConvenient temperature measurementFacilitate thermal insulation designCryogenic temperature measurementTemperature measurement of moving solidsHeat leakEngineering

The invention discloses a rotor temperature measurement simulated system and method for a low-temperature centrifugal type fluid machine. The system comprises a refrigerator, the centrifugal type fluid machine to be measured, a flowmeter, a flow control valve, a dynamic fluid machine and a heater connected via pipes. The refrigerator serves as a cold source, the dynamic fluid machine provides circulating power for a medium in the system, and a rotor of the centrifugal type fluid machine to be measured is kept static. The system can measure the rotor temperature when the centrifugal type fluidmachine transmits the low-temperature working medium, the complete internal temperature field and an axial heat leak can be obtained, and help is provided for design of a heat insulation structure ofthe whole machine.

Owner:ZHEJIANG UNIV

Water conveying sleeve and molding machine

The application provides a water conveying sleeve and a molding machine. The water conveying sleeve comprises a stator and a rotor. The stator comprises a base. At least a first fixing sleeve is sleeved on the base. A first flow channel is formed in the base. A second flow channel is formed in the first fixing sleeve. The first flow channel and the second flow channel are respectively used for connecting with an external pipeline. The rotor is simultaneously sleeved on the base and the first fixing sleeve and is used for fixing on a rotary table. A first movable interface and a second movableinterface which are respectively used for connecting with a mould are formed in the rotor. An annular first conveying groove is formed in the rotor or the base. The first conveying groove is respectively communicated with the first movable interface and the first flow channel. An annular second conveying groove is formed in the rotor or the first fixing sleeve. The second conveying groove is respectively communicated with the second movable interface and the second flow channel. That the medium temperature of the first flow channel and the second flow channel will not affect each other can beensured, the use effect of the medium passing through the water conveying sleeve is improved, and the requirements of the corresponding technology are met.

Owner:MODERN PRECISION PLASTIC & MOLD SHENZHEN CO LTD +1

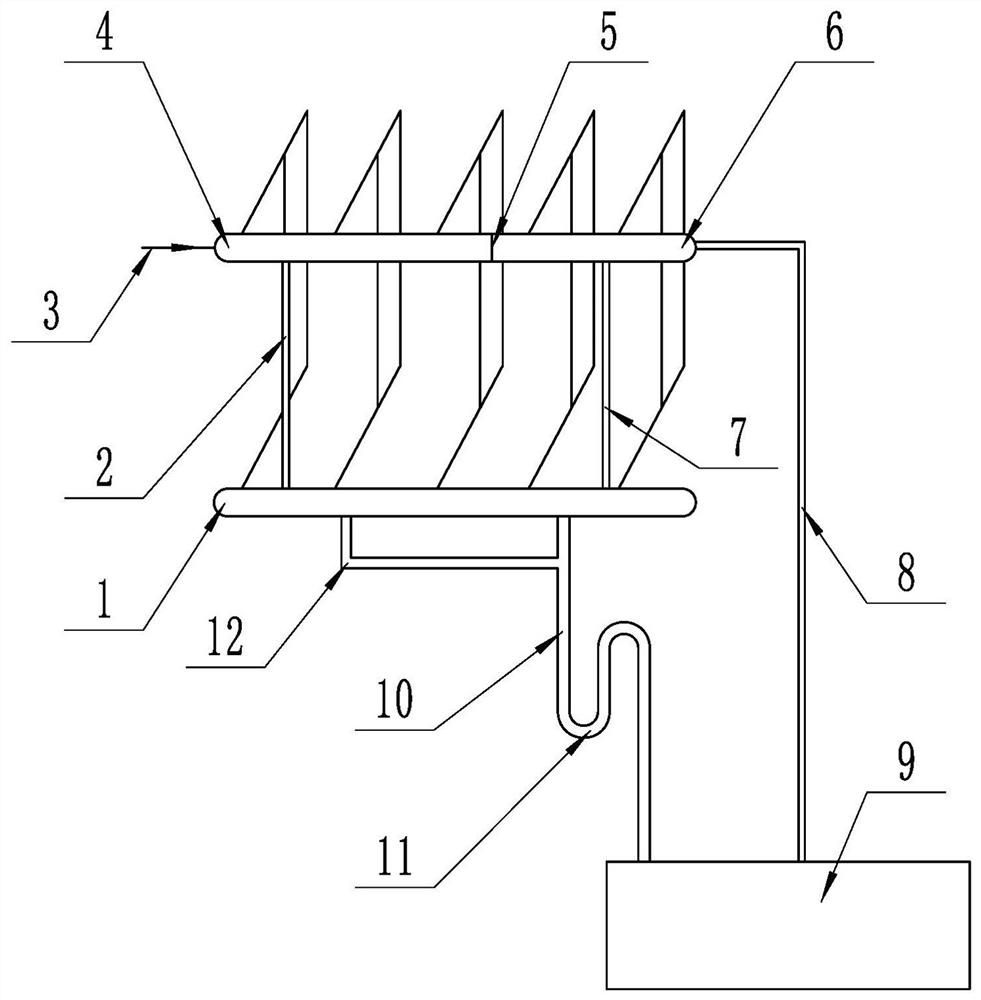

steam heat exchanger

ActiveCN112857076BBalanced pressure differenceImprove the effect of vapor-liquid separationSteam/vapor condensersStationary conduit assembliesMechanical engineeringMechanics

The invention is a steam heat exchanger, which comprises a composite header, a first-stage steam inlet header and a secondary steam inlet header are arranged above the composite header, and a transition is passed between the composite header and the secondary steam inlet header It also includes two sets of heat exchange tubes or heat exchange plates, wherein the inlet and outlet ends of the first set of heat exchange tubes or heat exchange plates are respectively connected to the first-stage steam inlet header and the composite header, and the second set of heat exchange tubes or The inlet and outlet ends of the heat exchange plate are respectively connected to the secondary steam inlet header and the composite header. The invention improves the steam flow rate along the flow direction of the condensate in the first-stage heat exchange tube and the heat exchange plate (tube) process, accelerates the discharge speed of the condensate film, greatly reduces the thickness of the condensate film, and makes it possible to generate The turbulent flow greatly improves the heat exchange efficiency in the first group of heat exchange plates (tubes). The invention greatly simplifies the pipeline structure including the header, and reduces the secondary pipeline connection between the heat exchanger groups. Make it more convenient to process and assemble.

Owner:李永堂

Preparation method of high-dielectric-constant BaO-TiO2-Nd2O3 capacitor ceramic material

InactiveCN109665836AImprove sintered densityImprove sintering performanceFixed capacitor dielectricCapacitanceCompression molding

The invention discloses a preparation method of a high-dielectric-constant BaO-TiO2-Nd2O3 capacitor ceramic material and belongs to the technical field of functional ceramics. The preparation method of the high-dielectric-constant BaO-TiO2-Nd2O3 capacitor ceramic material comprises the following steps of wet-ball-milling, mixing and drying BaO, TiO2, Nd2O3 and modifier; uniformly mixing the ball-milled and dried mixed powder with bonding agent for compression molding; sintering the compression-molded material in the atmosphere; re-sintering the sintered product in the atmosphere at 1130-1180 DEG C, keeping the temperature for 4-8 hours, and cooling the sintered product down to obtain the high-dielectric-constant BaO-TiO2-Nd2O3 capacitor ceramic material. Compared with the prior art, the preparation method of the high-dielectric-constant BaO-TiO2-Nd2O3 capacitor ceramic material takes BaO-Nd2O3-5TiO2 as a base system and introduces excessive TiO2 and dopes in Bi2O3-2TiO2 composite oxides and CeO2 for modification, so that the dielectric constant of the prepared high-dielectric-constant BaO-TiO2-Nd2O3 capacitor ceramic material can be improved, and the dielectric loss and the capacitance temperature coefficient of the high-dielectric-constant BaO-TiO2-Nd2O3 capacitor ceramic material can be reduced.

Owner:安庆市泽烨新材料技术推广服务有限公司

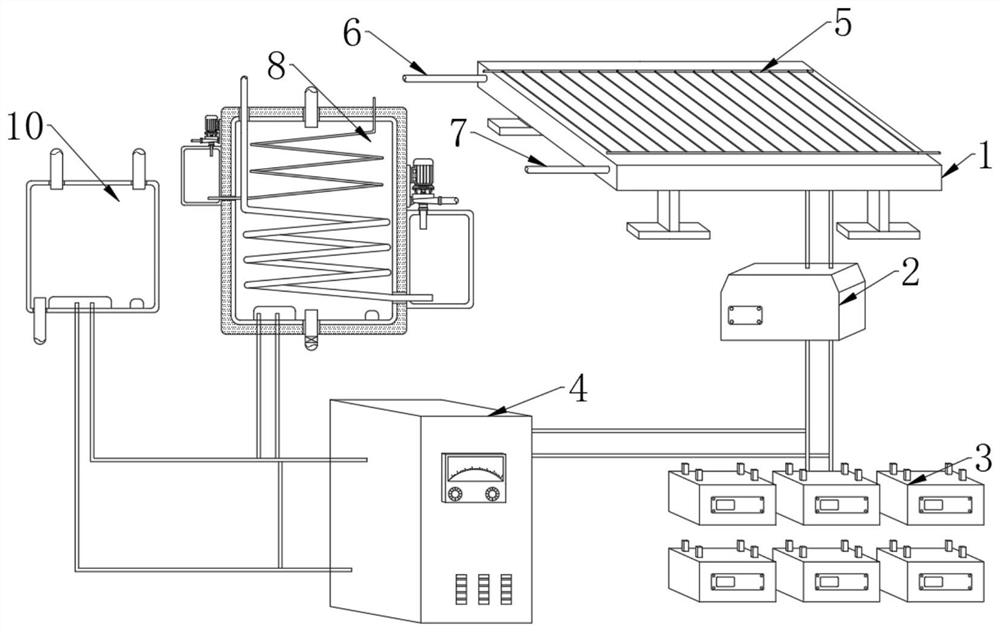

Solar photo-thermal utilization system

PendingCN113949341ATake advantage ofIncrease profitSolar heating energyPhotovoltaicsThermodynamicsCells panel

The invention discloses a solar photo-thermal utilization system which comprises a solar photo-thermal shell, a controller, a storage battery pack, an inverter, a heat exchange box and a heating box, wherein a base plate is arranged at the bottom in the solar photo-thermal shell, the inner wall of the solar photo-thermal shell is fixedly connected to a photovoltaic cell panel, a heat preservation sleeve is arranged on the side wall of the heat exchange box, and a first heat exchange mechanism used for utilizing solar photo-thermal is arranged in the solar photo-thermal shell. The heat exchange box is arranged, heat on the two faces of the photovoltaic cell panel can be utilized to generate hot water, power generation of the photovoltaic cell panel is matched, then the purpose of photo-thermal integrated utilization is achieved, and the energy utilization rate is increased; and secondly, a spiral second medium output pipe and a spiral first medium output pipe are arranged, the residence time of a medium in the heat exchange box is prolonged, and the heat exchange efficiency of the medium is improved. In addition, a first electric heater and a second electric heater are arranged, so that water flowing out of the water outlet pipe can meet the requirement of people for water temperature.

Owner:QINGDAO NENGAN HENGXIN TECH

A self-controlled energy-saving heat tracing system

ActiveCN104019360BRealize intelligent controlReduce wastePipeline systemsAutomatic controlTransport system

The invention discloses a self-control type energy-efficient heat tracing system and belongs to the fields of petroleum refining, petrochemical engineering and petroleum storage and transport. According to the heat tracing system, steam serves as a heat tracing medium. A control system is arranged in a steam heat tracing system. The self-control type energy-efficient heat tracing system comprises the steam heat tracing system and a blowing and sweeping air system. The blowing and sweeping air system and the steam heat tracing system are interlocked through a control unit when a petroleum refining and chemical engineering device or a petroleum storage and transport system is operated, so that servo operation of use / cutting of the steam heat tracing system and the operation state / shut-down state of the petroleum refining and chemical engineering device or the petroleum storage and transport system is achieved. An existing continuous inflow steam heat tracing mode is improved into a self-control intermittent feeding type steam heat tracing mode, system operation is good, intelligent control over the steam heat tracing system in the operation state of the petroleum refining and chemical engineering device or the petroleum storage and transport system is achieved, steam is reasonably and intermittently used, it is guaranteed that the temperature of the medium is lower than the temperature of the heat tracing steam, and waste of energy and consumption of water resources are effectively reduced.

Owner:PETROCHINA CO LTD

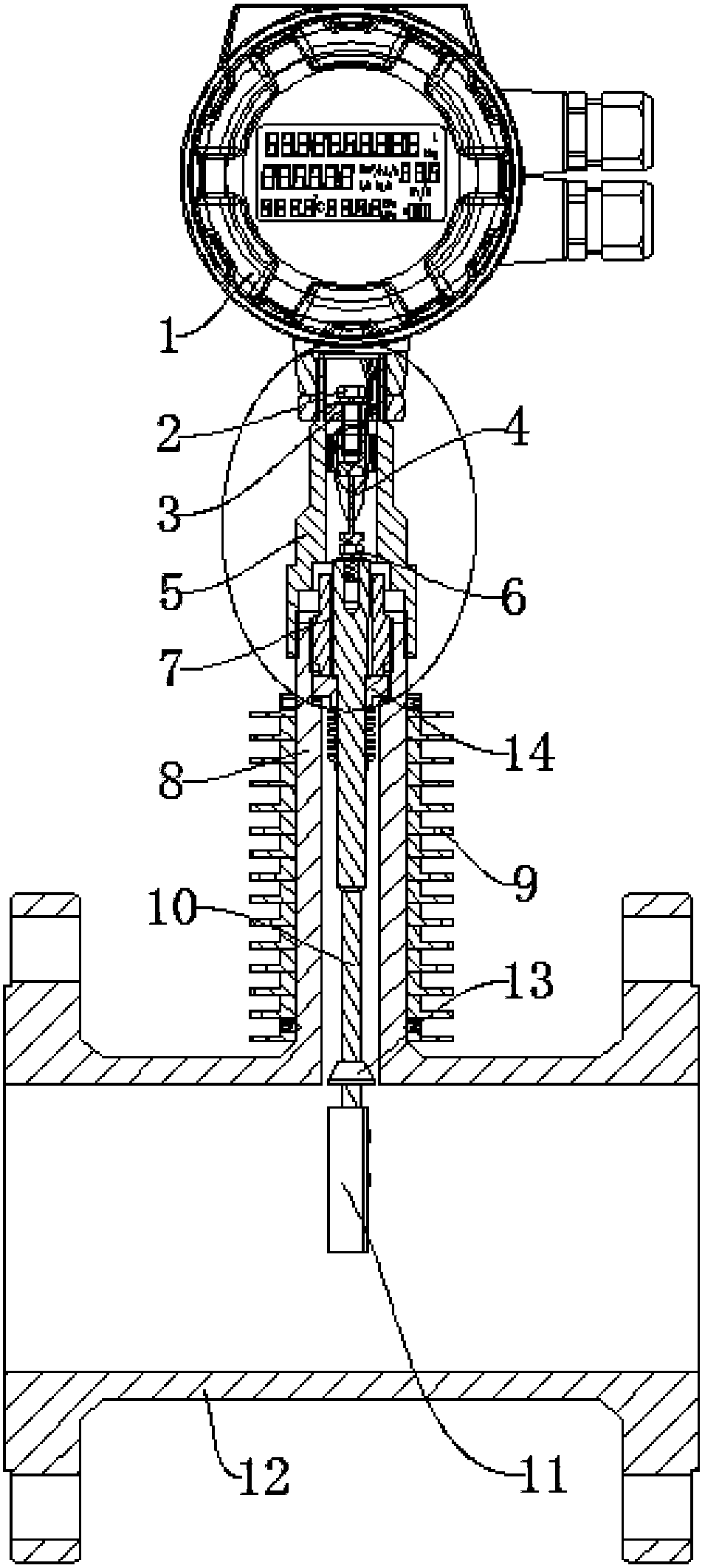

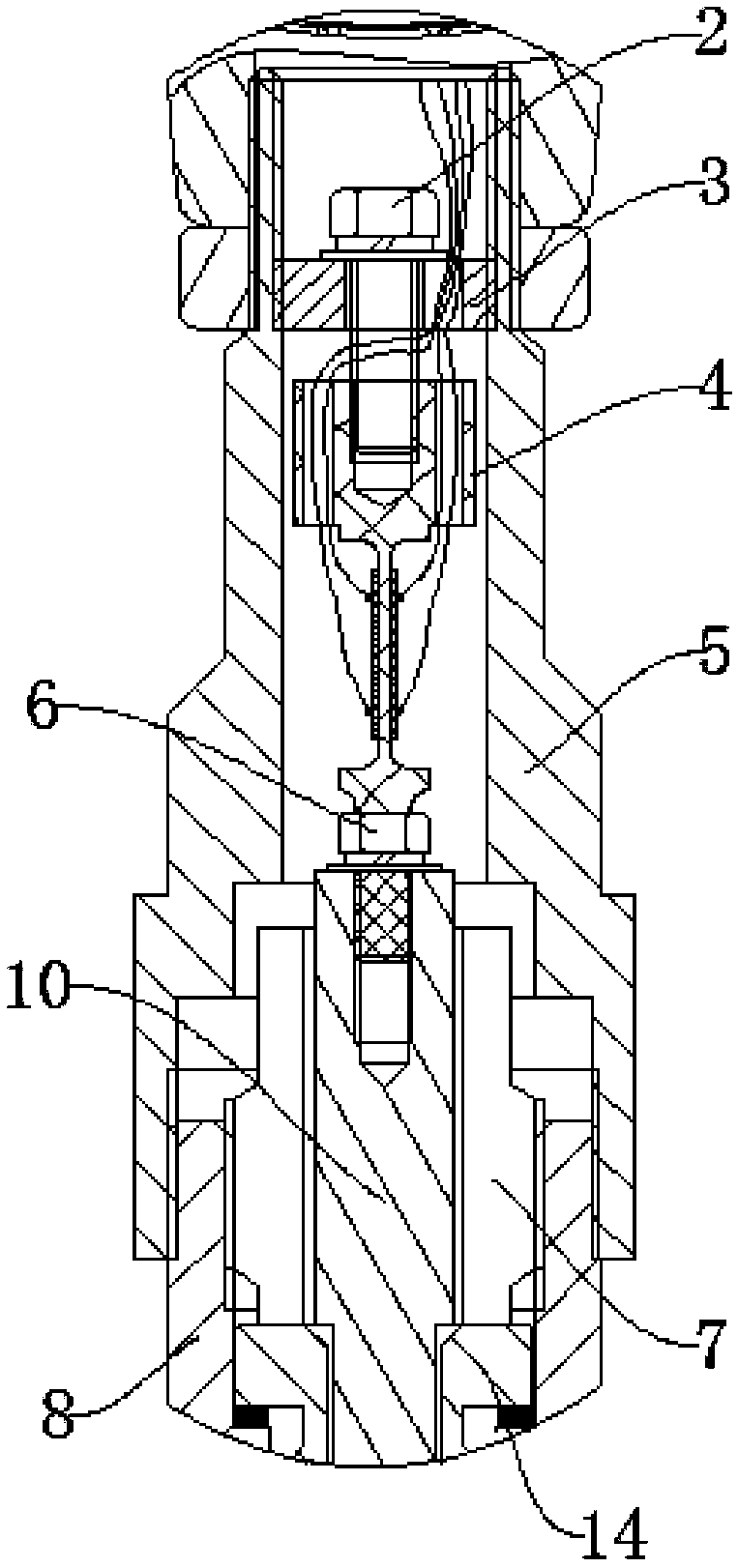

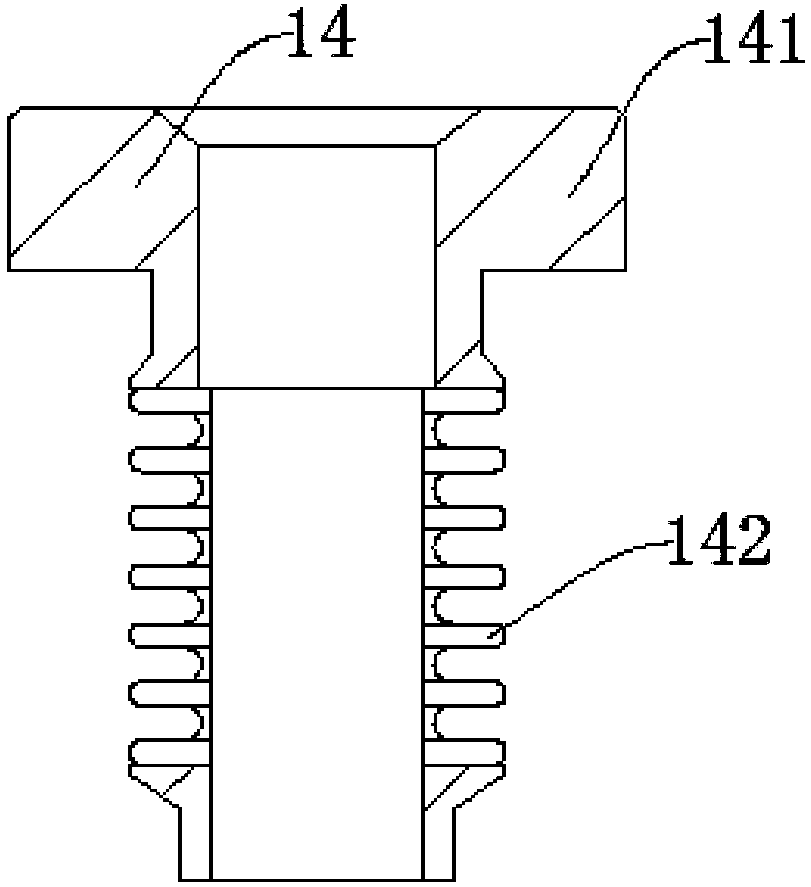

High-temperature medium online monitoring flowmeter

PendingCN108168640APrevents heat from being conducted upwardsGuaranteed ambient temperatureVolume meteringHeat sinkStrain gauge

The invention discloses a high-temperature medium online monitoring flowmeter. The high-temperature medium online monitoring flowmeter comprises a meter head and a casing; a connecting sleeve is arranged under the meter head through threads; a cantilever beam sensor is arranged in the connecting sleeve, and the cantilever beam sensor is electrically connected to the meter head; the cantilever beamsensor can convert the displacement of the target rod into an electrical signal and transmit the electrical signal to the meter head. The invention has the advantages that: heat sinks arranged on outer sides of a connecting seat can dissipate heat on the connecting seat outward in time, thereby reducing the temperature of a medium in the connecting seat; a heat insulating connecting member arranged on an upper end of the target rod can isolate the heat and prevent the heat from being conducted upward, thereby ensuring the environment temperature required by normal working of the cantilever beam sensor and improving the stability of the detected data; a thin plate-shaped deformation portion can improve the sticking firmness of strain sheets, can be used to detect micro deformation, and canincrease the applicable range of the flowmeter.

Owner:CHONGQING LIANDA INSTR

Workshop dust filter unit

InactiveCN104645726ASimple structureCompact structureDispersed particle filtrationCold airThermodynamics

A workshop dust filter unit is characterized in that the workshop dust filter unit comprises a cold air heating device, a delivery pipe, a separator and an induced draught fan; an upper part of the separator is connected with a warm-air exhausting pipeline; a lower part of an air-material separator is a discharge hole; one end of the warm-air exhausting pipeline is enclosed, and the other end of the warm-air exhausting pipeline is connected with the induced draught fan; and an exhaust port is connected with the induced draught fan. The separator is an integral structure. The workshop dust filter unit has a simple and compact structure, is small in size and is convenient to operate. With implementation of the overall scheme, system entrance and exit medium temperature is reduced, and energy consumption is saved.

Owner:宋凯

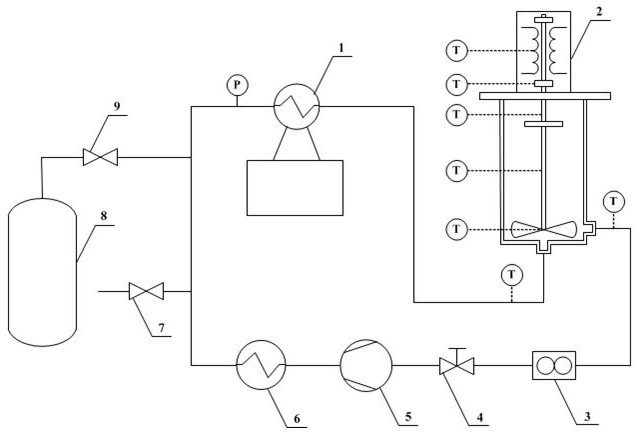

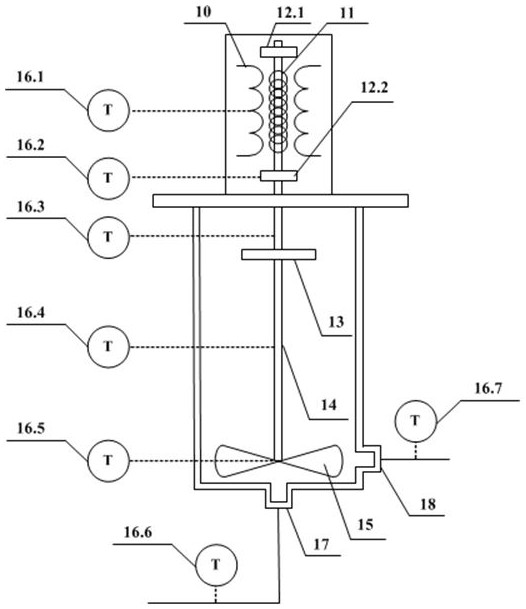

System for improving rapid heating and cooling of hot press

PendingCN113771408AReduce heat lossIncreased media flowWelding/cutting auxillary devicesAuxillary welding devicesProcess engineeringCold medium

The invention relates to a system for improving rapid heating and cooling of a hot press. The system is used for executing heating and cooling operation of the hot press. The rapid heating and cooling system comprises a processing center, a heat source module, a medium transmission module, a cold and hot oil exchange unit and a medium flow adjusting module, wherein the heat source module is used for heating a medium of the hot press, and the cold and hot oil exchange unit is used for directly sending the directionally output medium back to the heat source module, the medium flow adjusting module is used for setting the flow rate of the medium to be the highest threshold value. The system can effectively control the situation of energy waste caused by excessive loss of heat energy generated during exchange of a hot medium and a cold medium, realizes rapid heating and cooling, reduces the heat energy loss of the hot press, and the medium can rapidly flow through a heating area to improve the heat exchange rate, so that heating is accelerated, the cold medium can rapidly flow out to shorten the retention time, and the heat loss is reduced to a certain extent.

Owner:林州致远电子科技有限公司

A rotor temperature measurement and simulation system and method for a low-temperature centrifugal fluid machine

ActiveCN110095206BConvenient temperature measurementFacilitate thermal insulation designCryogenic temperature measurementTemperature measurement of moving solidsWorking fluidThermal insulation

Owner:ZHEJIANG UNIV

Cooling device for 1500°C ultra-high temperature valve body

ActiveCN104455708BReduce direct washoutImprove reliabilityValve members for heating/coolingEngineeringWater cooling

A cooling device of a 1500 DEG C ultrahigh-temperature valve body comprises a medium inlet passage, a valve body middle port position, a valve cover and an end cap. The medium inlet passage and the valve body middle port position are arranged on the valve body and connected with each other, a high-temperature ceramic heat-insulating lining cooling structure is arranged on the medium inlet passage on the valve body, a valve body middle port is provided with a valve body middle port water cooling system, and requirements on safe and reliable running under a working condition of 1500 DEG C and 5.0 MPa are met. Part of heat of a high-temperature medium is absorbed by a midbody water cooling lower portion where pressure drop is formed, and pressure and temperature of the medium are further lowered; due to the structure, direct scouring of a valve seat sealing face by the high-temperature medium can be greatly reduced, service life of the valve is prolonged, and running reliability of the valve is improved.

Owner:LANZHOU HIGH PRESSURE VALVE

Energy saving heat exchanger

ActiveCN103743087BReduce surface temperatureExtended service lifeWater heatersPlate heat exchangerBiochemical engineering

Owner:无锡华能电热器材有限公司

Marine seawater quick freezer

ActiveCN106091541BAvoid spillingReduce consumptionLighting and heating apparatusDomestic refrigeratorsHanging basketEngineering

Owner:辽宁金丰粮食机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com