steam heat exchanger

A technology of heat exchanger and steam, which is applied in the direction of heat exchanger shell, steam/steam condenser, heat exchange equipment, etc. The heating device occupies a large area, etc., so as to reduce the secondary anti-corrosion operation, reduce the workload of cooling, and reduce the effect of pipe connection and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

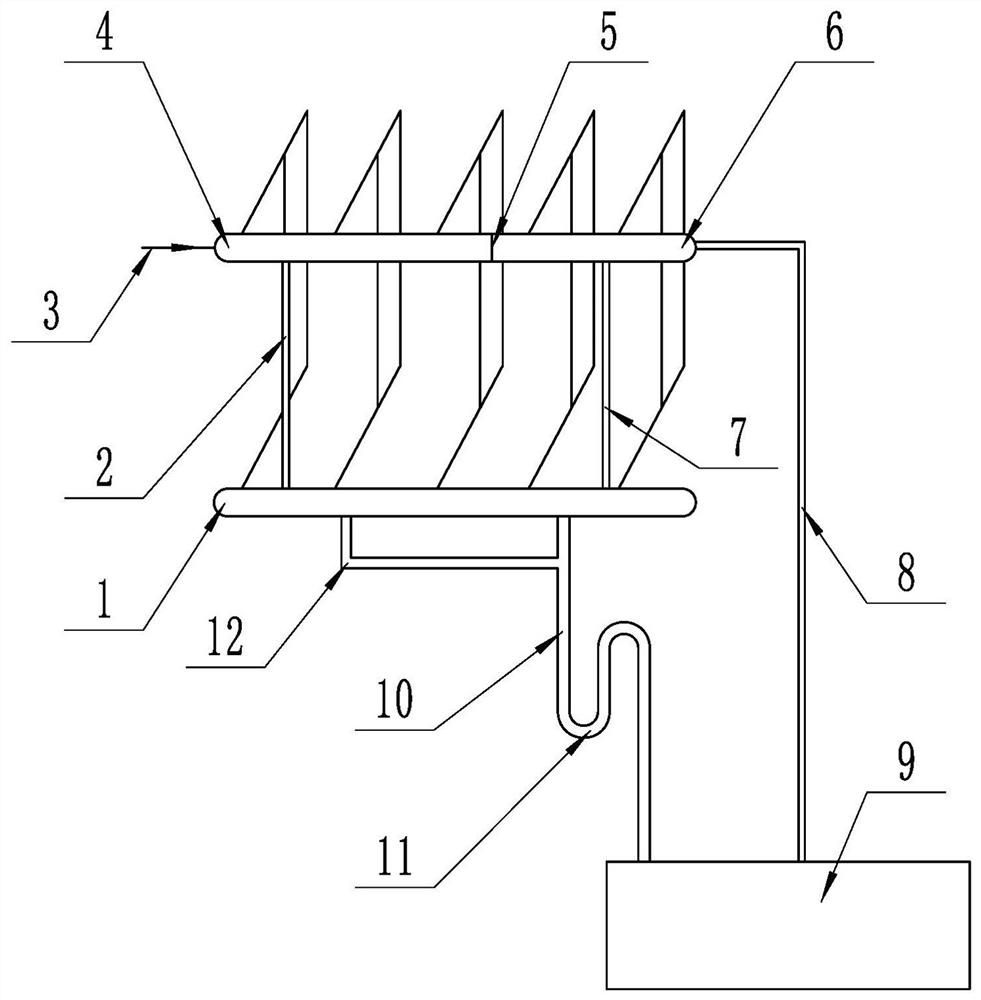

[0021] like figure 1 , the embodiment of the present invention includes a composite header 1 , a first-stage steam inlet header 4 and a secondary steam inlet header 6 are arranged above the composite header 1 . The primary inlet steam header 4 is provided with an inlet steam pipe 3 . As an optimized solution, the first-stage steam inlet header 4 and the second-stage steam inlet header 6 are two sections of headers separated by the same header and separated by an internal partition 5 . The composite header 1 and the secondary inlet steam header 6 communicate with each other through a transition pipe 7 . It also includes two groups of heat exchange tubes or heat exchange plates, wherein the inlet and outlet ends of the first group of heat exchange tubes or heat exchange plates are respectively connected to the first-stage steam inlet header 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com