Compressor and its control method, air conditioner

A control method and compressor technology, which is applied in the direction of machines/engines, refrigerators, refrigeration components, etc., can solve problems such as increased compressor vibration, poor working conditions, and crankshaft reversal, so as to reduce vibration amplitude and improve system life , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

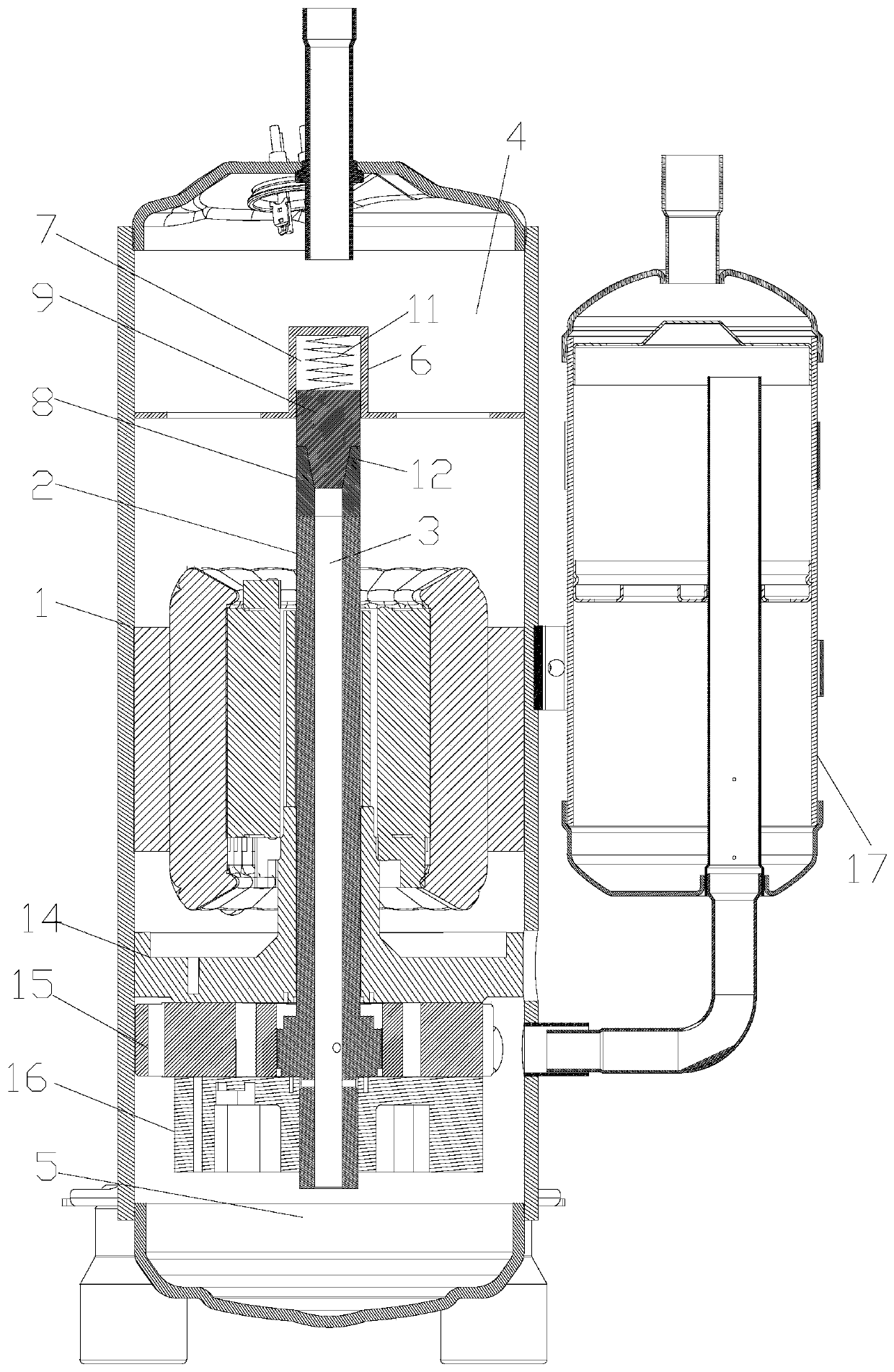

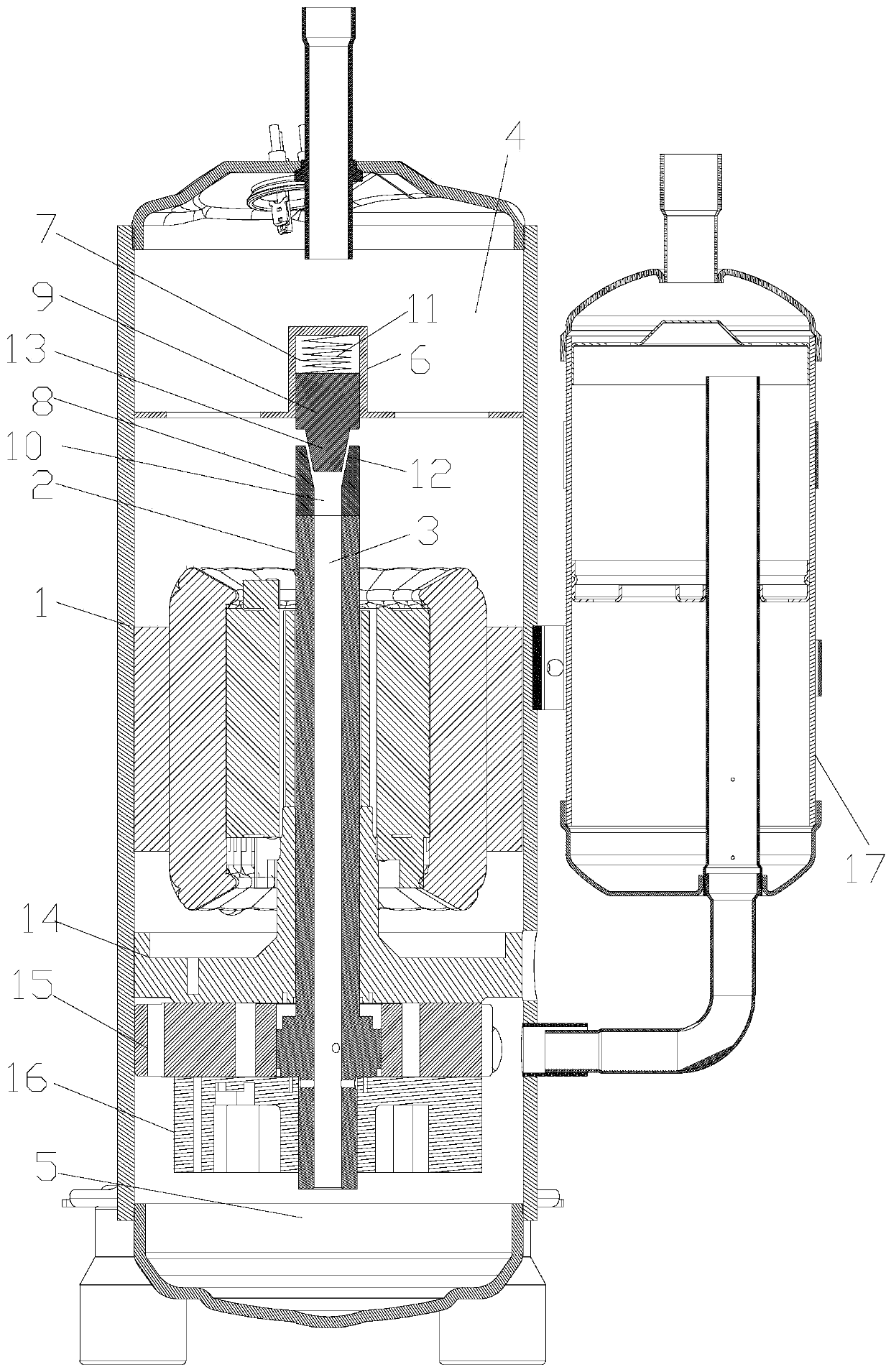

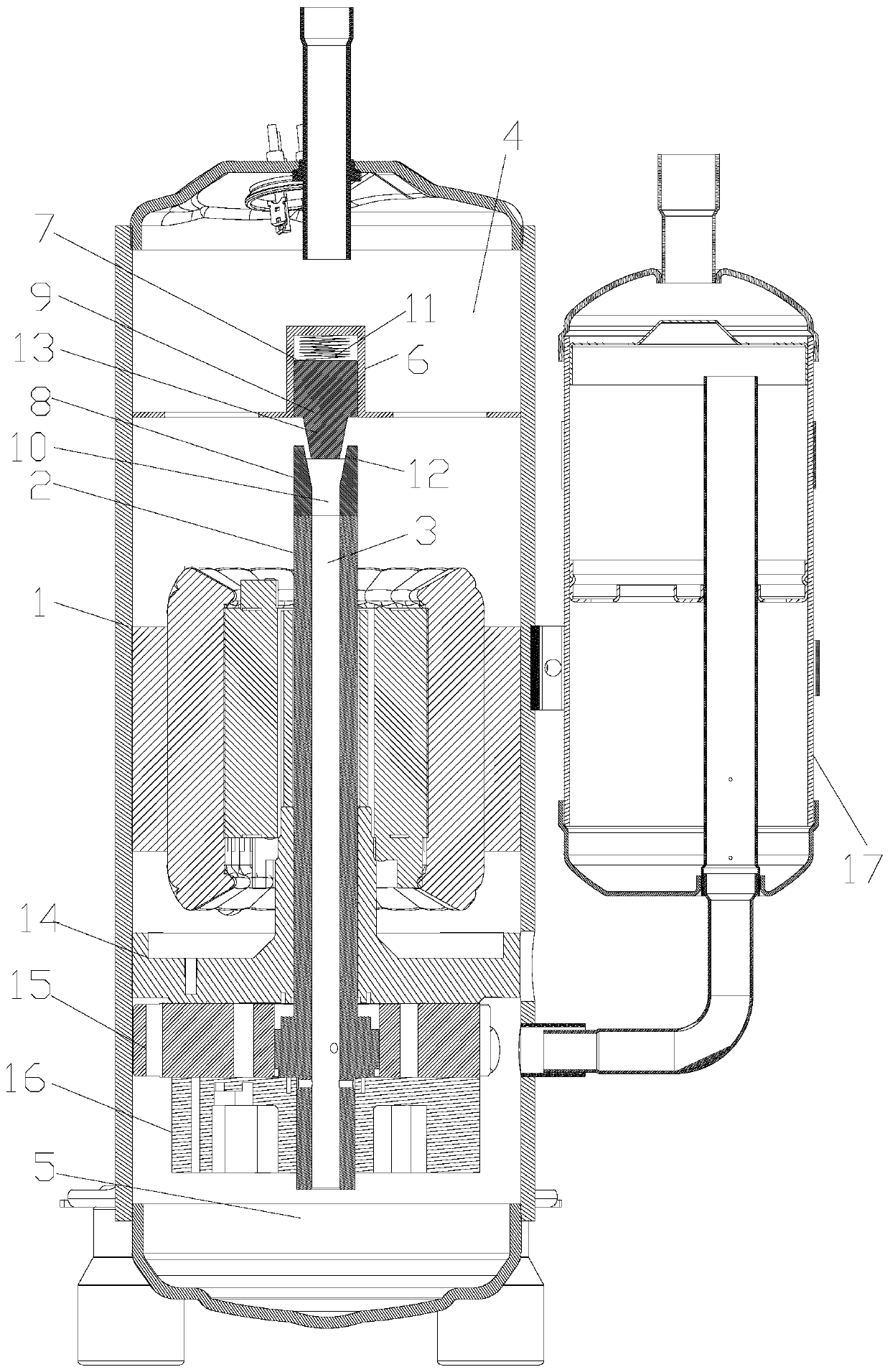

[0046] see in conjunction Figure 1 to Figure 5 As shown, according to the embodiment of the present invention, the compressor includes a housing 1, a crankshaft 2 is arranged in the housing 1, and the inner cavity of the housing 1 forms a high-pressure discharge chamber 4 and a low-pressure chamber 5, and the high-pressure discharge chamber 4 and the low-pressure chamber The cavity 5 can be selectively communicated through the crankshaft 2 .

[0047] When the compressor starts or stops suddenly, the high-pressure discharge chamber 4 and the low-pressure chamber 5 can be connected through the crankshaft 2, so as to release the pressure in time, balance the pressure difference between the high-pressure discharge chamber 4 and the low-pressure chamber 5, and reduce or eliminate the Refrigerant pressure load, improve compressor start-up and continuous start-up performance, achieve continuous start-up effect in a very short time, reduce vibration amplitude during compressor start-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com