Vapor-liquid separation device

A technology of vapor-liquid separation and vapor-liquid mixing, which is applied in liquid cleaning methods, heating water/sewage treatment, water/sewage treatment, etc., and can solve the problems of heavy salt liquid entrainment in secondary steam and poor vapor-liquid separation performance , to achieve the effect of improved secondary steam separation ability, strong vapor-liquid separation ability, and improved vapor-liquid separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

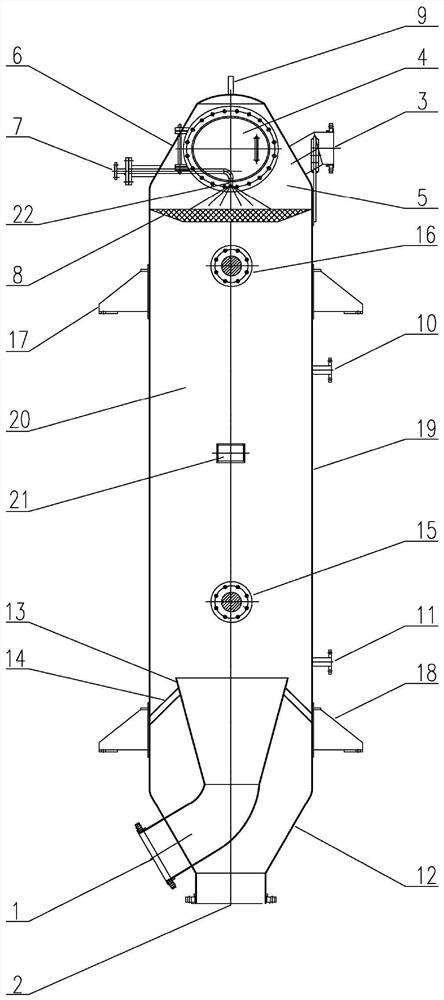

[0027] Such as figure 1 As shown, the vapor-liquid separation device of the present embodiment comprises a vapor-liquid mixing chamber 20, a steam chamber 5, a liquid-dispersing cylinder 13 and a demister 8, the liquid-dispersing cylinder 13 is arranged at the bottom of the vapor-liquid mixing chamber 20, and the liquid-dispersing cylinder 13 The inlet end of the liquid tank 13 communicates with the material water inlet 1, and the outlet end of the bulk liquid cylinder 13 communicates with the vapor-liquid mixing chamber 20. The steam chamber 5 is arranged above the vapor-liquid mixing chamber 20 and communicates with the vapor-liquid mixing chamber 20 through the demister 8. A material water outlet 2 is provided at the lower end of the vapor-liquid mixing chamber 20, and a secondary steam outlet 3 is provided at the upper end of the steam chamber 5.

[0028] In this embodiment, the vapor-liquid mixing chamber 20 is mainly used for the separation of water and steam in the mate...

Embodiment 2

[0037]This embodiment uses the vapor-liquid separation device of Embodiment 1 to separate the material water formed by the secondary steam in the multi-effect evaporation crystallization process; wherein, the height-to-diameter ratio of the cylinder 19 is set to 3.2, and the outlet end of the bulk liquid cylinder 13 is connected to the The vertical height between the lower liquid level gauge interfaces 11 is set to 300 mm, and the vertical height between the cleaning nozzle 22 and the demister 8 is set to 300 mm.

[0038] The quality index of material water is: pH=6-8, COD=150mg / L, ammonia nitrogen=25mg / L, total hardness (as CaCO 3 )=10mg / L, total alkalinity (as CaCO 3 )=300mg / L, chloride ion=27500mg / L, conductivity=113500μs / cm.

[0039] The separation process steps are as follows: the internal surface area of the vapor-liquid separation device in embodiment 1 is 25m 2 , will be 30m 3 The above-mentioned material water is input into the steam heater through the circulatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total alkalinity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Average conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com