Workshop dust filter unit

A dust filter device and workshop technology, which is applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of large size of separator and dust collector, high initial temperature of air flow, large power consumption, etc., and achieve reduction temperature, energy saving, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

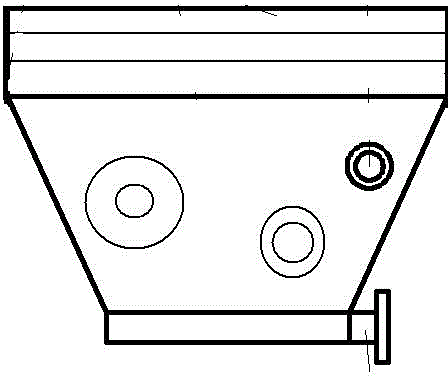

Image

Examples

Embodiment 1

[0013] The invention provides a workshop dust filtering device, characterized in that: said workshop dust filtering device includes a cold air heating device, a conveying pipeline, a separator, and an induced draft fan; The lower part is the discharge port, one end of the hot air exhaust pipe is closed, the other end is connected to the induced draft fan, and the exhaust port is connected to the induced draft fan.

[0014] The workshop dust filtering device according to claim 1, characterized in that: the diameter of the vertical part of the conveying pipeline is larger than that of other parts.

[0015] The workshop dust filtering device according to claim 1, characterized in that: the upper part of the separator is cylindrical, and the lower part is rectangular parallelepiped.

[0016] The separator is an integral structure. The workshop dust filter device is simple in structure, compact, small in size and easy to operate. The implementation of the overall scheme of the in...

Embodiment 2

[0018] The invention provides a workshop dust filtering device, characterized in that: said workshop dust filtering device includes a cold air heating device, a conveying pipeline, a separator, and an induced draft fan; The lower part is the discharge port, one end of the hot air exhaust pipe is closed, the other end is connected to the induced draft fan, and the exhaust port is connected to the induced draft fan.

[0019] The workshop dust filtering device according to claim 1, characterized in that: the diameter of the vertical part of the conveying pipeline is larger than that of other parts.

[0020] The workshop dust filtering device according to claim 1, characterized in that: the upper part of the separator is cylindrical, and the lower part is rectangular parallelepiped.

[0021] The workshop dust filtering device according to claim 1 or 3, characterized in that: said separator is an integral structure.

[0022] The workshop dust filter device is simple in structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com