Energy saving heat exchanger

An energy-saving heat exchanger and heat exchange tube technology, applied in the field of heat exchange, can solve the problems of large external heat loss, high processing requirements and short service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

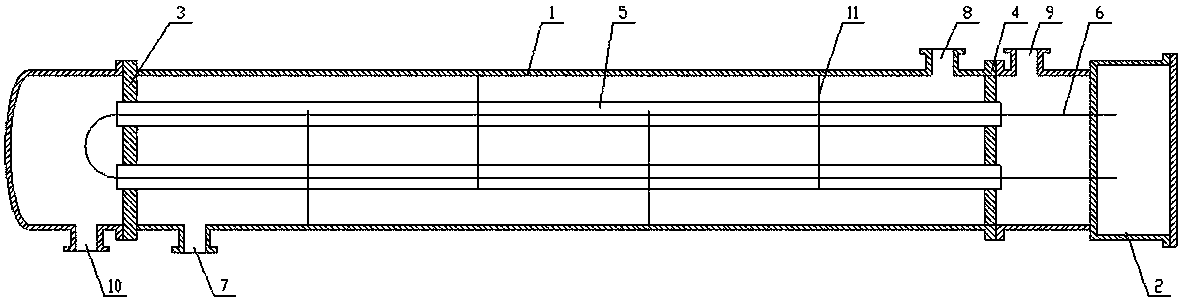

[0009] like figure 1 As shown, the present invention includes a shell 1, one end of the shell 1 is closed, and a junction box 2 is provided at the other end, and a first tube sheet 3 and a second tube sheet 4 are arranged in the shell 1 perpendicular to the axial direction of the shell. , the shell 1 is divided into three independent cavities, the middle cavity forms the shell side, a number of heat exchange tubes 5 are arranged between the first tube sheet 3 and the second tube sheet 4, and the heat exchange The tube 5 runs through the first tube sheet 3 and the second tube sheet 4 , thereby connecting the cavities at both ends of the casing 1 . The heat exchange tube 5 is provided with a U-shaped electric heating tube 6 connected to the junction box 2 , and the U-shaped electric heating tube 6 passes through two heat exchange tubes 5 in sequence. For the convenience of assembly and disassembly, the two ends of the U-shaped electric heating tube 6 are connected with the junc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com