A rotor temperature measurement and simulation system and method for a low-temperature centrifugal fluid machine

A technology of fluid machinery and rotor temperature, which is applied in low-temperature temperature measurement, temperature measurement of moving solids, thermometers, etc., can solve the problem of inability to measure rotor temperature, and achieve the effect that is beneficial to the design of thermal insulation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

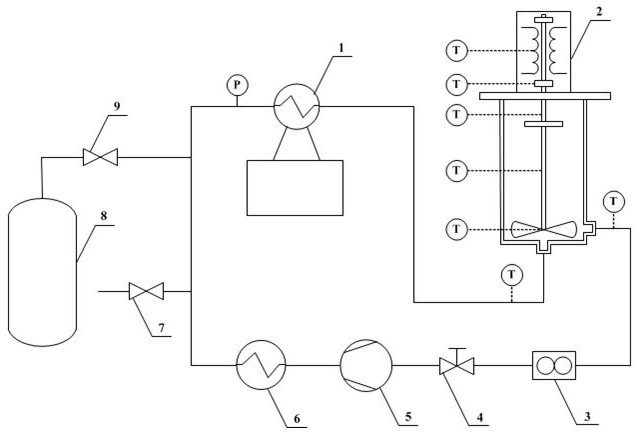

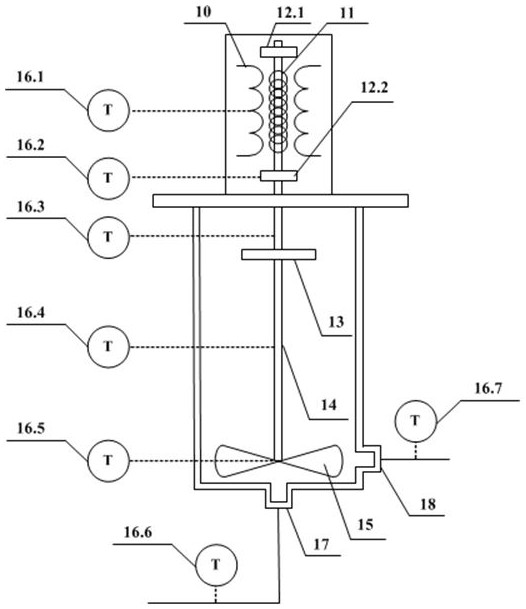

[0049] Example 1 Test the influence of inlet medium temperature on fluid machine 2 rotor temperature

[0050] Turn on the power fluid machine 5 and the refrigerator 1, and the system starts to cool down. When the cooling capacity provided by the refrigerator 1 is balanced with the leakage heat of the system, the temperature at the inlet temperature measuring point 16.6 drops to the lowest value, and the rotor temperature is measured. Keep the electric power of the stator electric heating wire 10, the rotor electric heating wire 11, the upper rotor bearing 12.1 and the lower rotor bearing 12.2 electric heating sheet constant, turn on the heater 6, and set the heating power. Due to the increase of the heat load of the system, the temperature of the inlet temperature measuring point 16.6 will rise at this time, and it will stabilize after a period of time, and the rotor temperature will be measured again. Change the heating power of heater 6 afterwards, carry out the test of same...

Embodiment 2

[0051] Embodiment 2 Test the influence of the heat generated inside the motor on the temperature of the fluid machine 2 rotor

[0052] Adjust the electric heating power of the stator electric heating wire 10, the rotor electric heating wire 11, the upper rotor bearing 12.1 and the lower rotor bearing 12.2 electric heating sheet to the maximum value, turn on the power fluid machine 5 and the refrigerator 1, and the system starts to cool down. When the cooling capacity provided by machine 1 is in balance with the leakage heat of the system, the temperature at the inlet temperature measuring point 16.6 drops to the lowest value, and the rotor temperature is measured. Afterwards, reduce the power of the heating wire and heating plate in the motor, and reduce the thermal load of the system, so the temperature at the inlet temperature measuring point 16.6 will be further reduced, but to control the variable, that is, to keep the temperature at the inlet temperature measuring point 16...

Embodiment 3

[0053] Example 3 Test the influence of heat sink position on fluid machine 2 rotor temperature

[0054] Turn on the power fluid machine 5 and the refrigerator 1, and the system starts to cool down. When the cooling capacity provided by the refrigerator 1 is balanced with the leakage heat of the system, the temperature at the inlet temperature measuring point 16.6 drops to the lowest value, and the rotor temperature is measured. Maintain the electric power of the stator electric heating wire 10, the rotor electric heating wire 11, the upper rotor bearing 12.1 and the lower rotor bearing 12.2 electric heating sheet to keep constant, and change the axial position of the heat sink 13. At this time, the temperature distribution in the axial direction of the rotor changes. , the heat load of the system also changes accordingly, and the temperature at the inlet temperature measuring point 16.6 will also be slightly different. Adjust the heating power of the heater 6 to keep the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com