Device for enhancing on-line quenching stability of extruded aluminum profile

A stable and aluminum profile technology, applied in the field of aluminum profile extrusion production, can solve problems such as high equipment performance and configuration requirements, and achieve the effect of ensuring performance and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

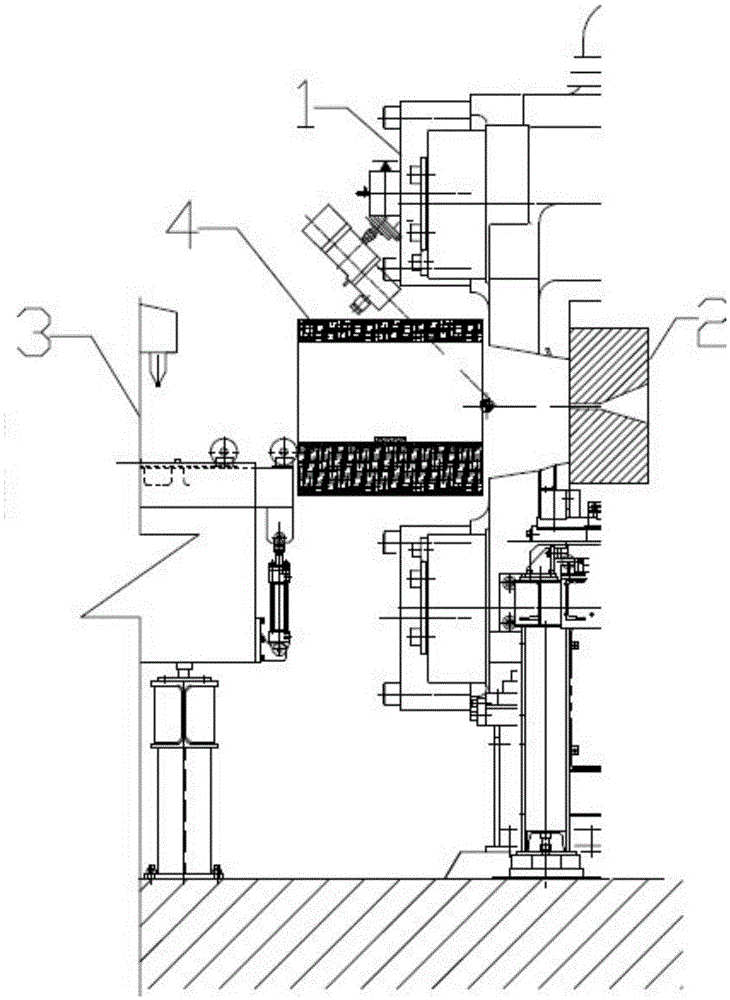

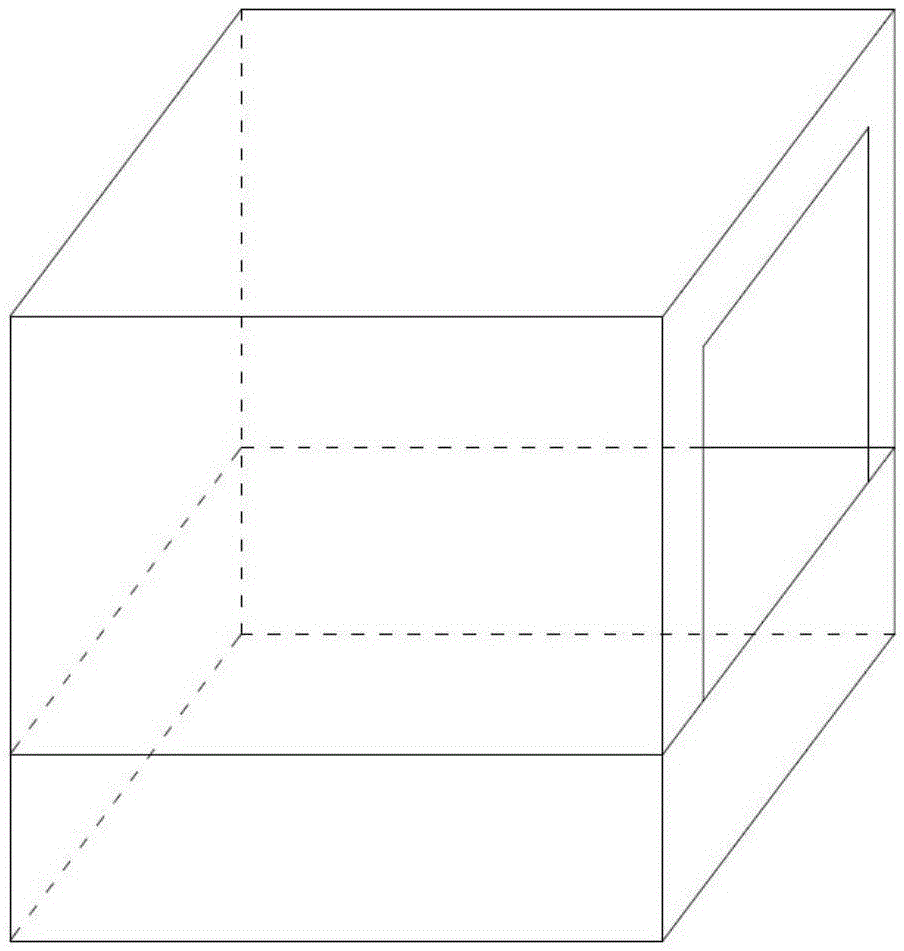

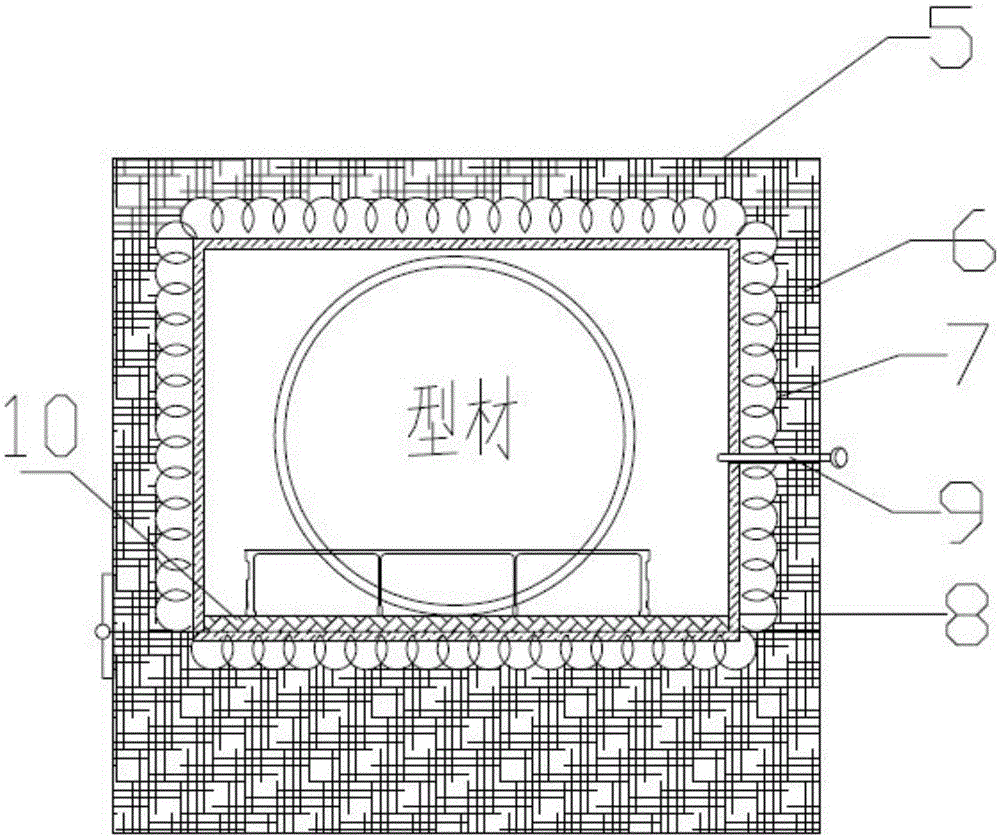

[0022] A device for improving the stability of on-line quenching of extruded aluminum profiles, comprising an automatic heat preservation device 4 arranged between the outlet of a die 2 on an extruder 1 and a quenching device 3, the automatic heat preservation device 4 includes a steel shell 5, Heating device 7, heat dissipation copper plate 8, temperature measuring device 9, graphite pad 10 and thermal insulation material 6, the steel shell 5 is a cuboid, and the steel shell 5 is provided with a high temperature resistant felt curtain near the outlet of the mold 2, A layer of thermal insulation material 6 is evenly distributed on the inner surface of the steel casing 5, and a heating device 7 is evenly distributed on the inner side of the thermal ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com