Capacitive temperature sensor and using method thereof

A temperature sensor and capacitor technology, applied in the field of temperature sensors and capacitive temperature sensors, can solve the problems of inability to measure large devices, influence of absorption rate measurement, fast response speed, etc., and achieve wide application range, true and reliable data, and small system error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

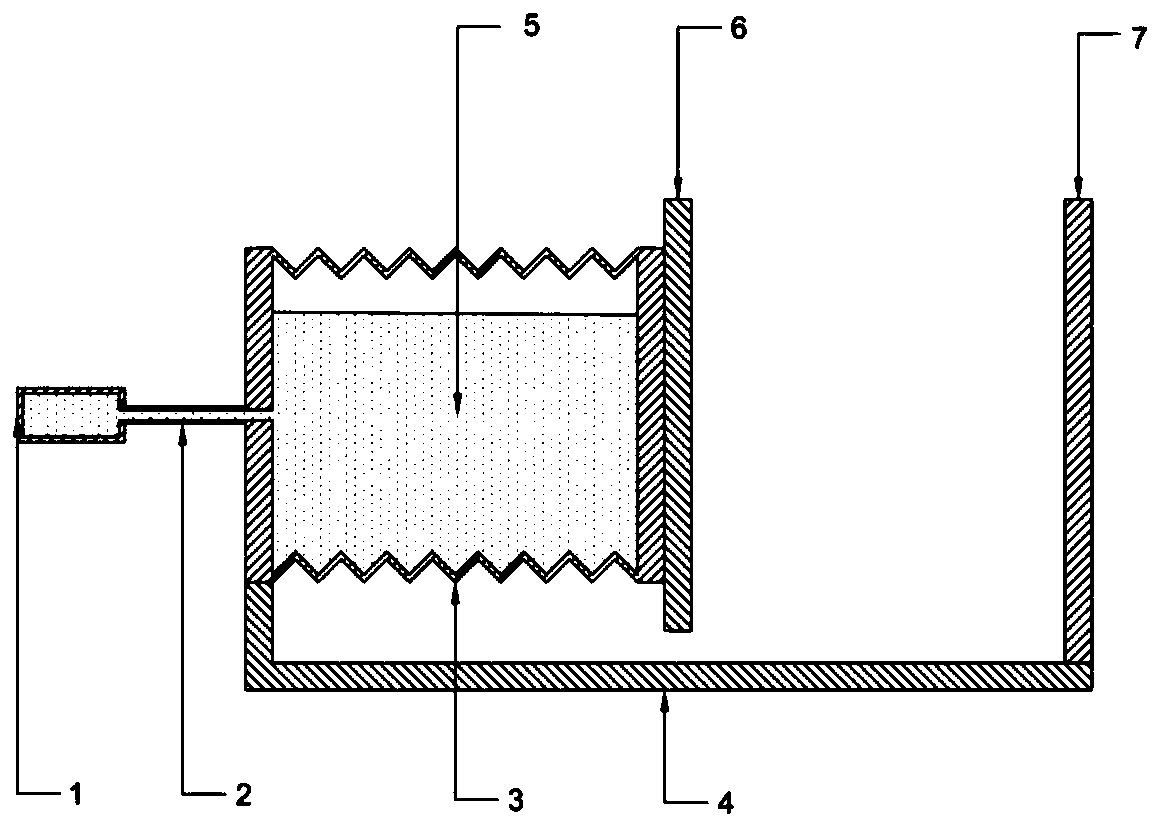

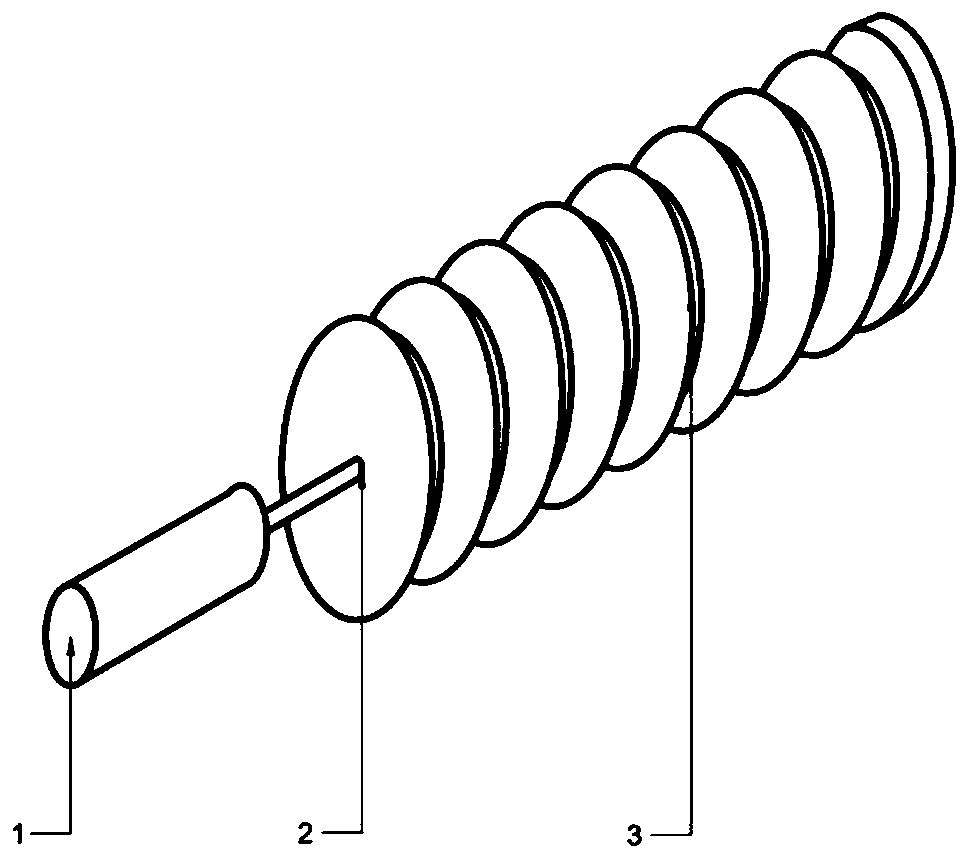

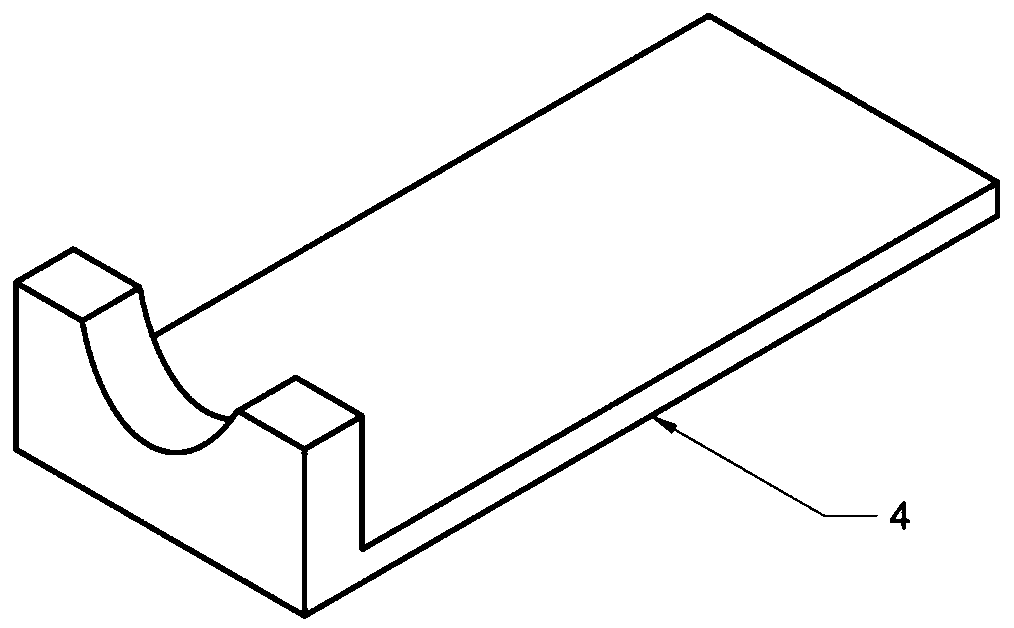

[0028] Such as figure 1 As shown, a capacitive temperature sensor of the present invention is composed of a temperature sensing package 1, a capillary tube 2, a bellows 3, a base 4, a temperature sensing working medium 5, a capacitor left plate 6 and a capacitor right plate 7, wherein the The base 4 is a ∟-shaped plate structure, and a semicircular groove is opened on the vertical plate, and one end of the bellows 3 is fixedly connected in the semicircular groove, and is fixedly connected with the capillary 2 and the temperature sensing package 1 outward in turn. , the other end hangs on the horizontal plate of the base 4, and its end face is fixedly connected to the left pole plate 6 of the capacitor, and the right pole plate 7 of the capacitor is vertically fixedly connected to the left pole plate 6 of the capacitor with a gap. On the base 4 ; the connected bellows 3 , capillary 2 and temperature-sensing package 1 are filled with the same temperature-sensing working medium 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com