Ultrahigh temperature pressure sensor and manufacturing method thereof

A pressure sensor, ultra-high temperature technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., can solve the problems of sensor temperature drift increasing and affecting sensor measurement accuracy, etc., to achieve small size, good stability, The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

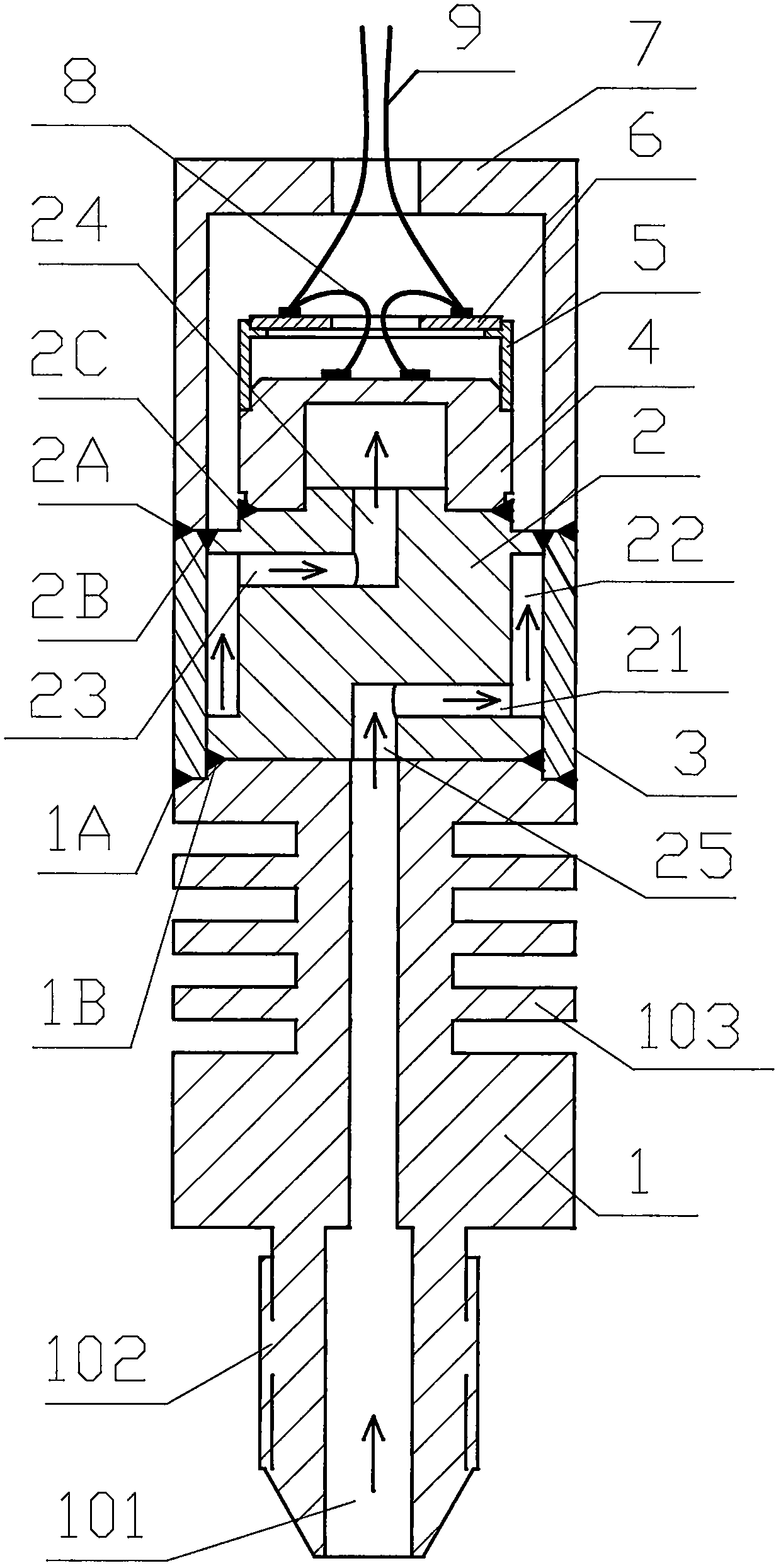

[0032] like figure 1 As shown, an ultra-high temperature pressure sensor is composed of a pressure guiding part 1, a pressure guiding part 2, a cooling ring 3 and a casing 7. The lower part of the pressure introducing part 1 is processed with an external thread 102 , the upper part is processed with a cooling fin 103 for effective heat dissipation, and the center is processed with a through pressure introducing hole 101 . For the pressure introducing part with cooling fins, when the medium passes through the pressure introducing hole 101 when the upper part is sealed and does not flow, the temperature of the medium can be effectively reduced by about 50%.

[0033] The pressure guiding member 2 is a cylinder. The upper central position of the pressure guiding member 2 is provided with an upper central pressure introduction hole 24, and the lower central position is opened with a lower central pressure introduction hole 25 which is not connected with the upper central pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com