Self-control type energy-efficient heat tracing system

A high-efficiency energy-saving, control system technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as energy waste, water consumption, etc., to reduce water consumption, reduce energy waste, The effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

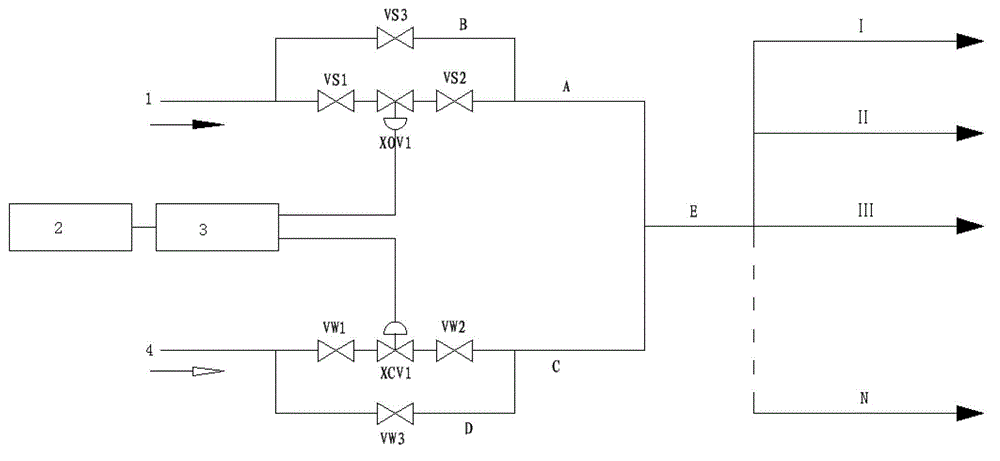

[0061] see figure 1 As shown, the control system set in the steam heating system in the embodiment of the present invention is the total steam source control type, at least including: the heating steam cut-off valve XOV1, the front hand valve Vs1 of the heating steam cut-off valve, the heating steam cut-off valve The rear hand valve Vs2 of the heating steam cut-off valve, the auxiliary line valve Vs3 of the heating steam cut-off valve, the blowing air cut-off valve XCV1, the front hand valve Vw1 of the blown wind cut-off valve, the back hand valve Vw2 of the blown wind cut-off valve, and the blown wind cut-off valve The auxiliary line valve Vw3 of the valve, the main heating steam circuit A, the heating steam circuit B, the main sweeping air circuit C, the sweeping air circuit D, the total steam source summary pipeline E, the first heating pipeline I, the second Two heating pipelines II, the third heating pipeline III, the Nth heating pipeline N, heating steam inlet 1, oil ref...

Embodiment 2

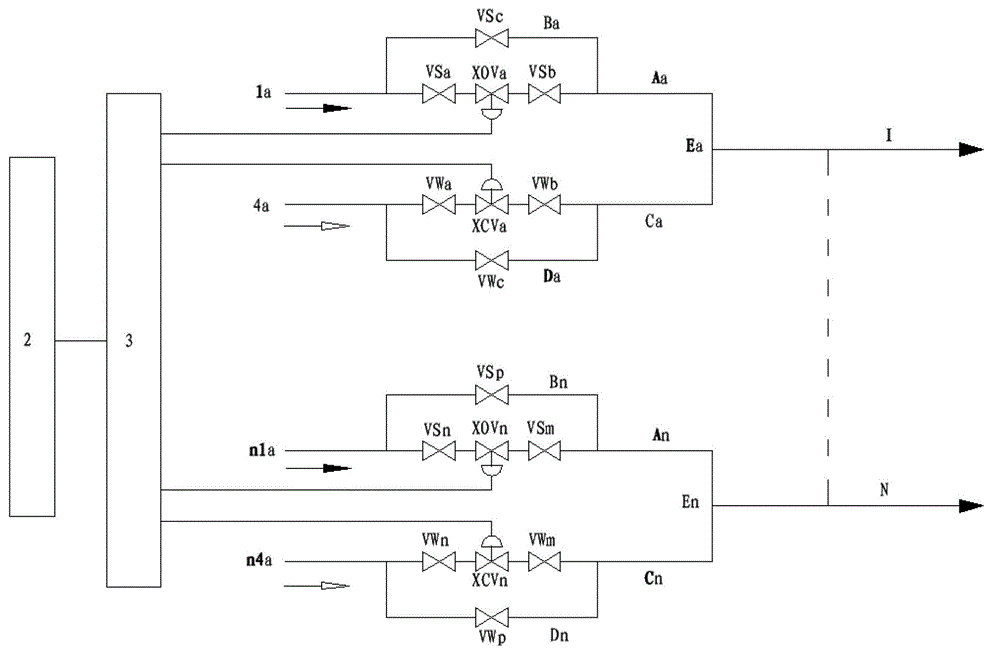

[0069] see figure 2 As shown, the control system set in the steam heat tracing system in the embodiment of the present invention is the steam source control type, at least including: the first traced steam cut-off valve XOVa, the front hand valve Vsa of the first traced steam cut-off valve , the back valve Vsb of the first heating steam cut-off valve, the auxiliary line valve Vsc of the first heating steam cut-off valve, the first blowing air cut-off valve XCVa, the front hand of the first blowing air cut-off valve Valve Vwa, the back valve Vwb of the first blowing air cut-off valve, the auxiliary line valve Vwc of the first blowing air cut-off valve, the Nth heating steam cut-off valve XOVn, the Nth heating steam cut-off valve The front hand valve Vsn, the back valve Vsm of the Nth heating steam cut-off valve, the auxiliary line valve Vsp of the Nth heating steam cut-off valve, the Nth purge air cutoff valve XCVn, the Nth purge air cutoff valve The front hand valve Vwn of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com