Slab laser module with wave-front distortion self-correction ability

A wavefront distortion, laser module technology, applied in lasers, laser parts, phonon exciters, etc., can solve problems such as difficult to achieve the fill factor of the slat medium, system instability, thermal management and optical path design defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

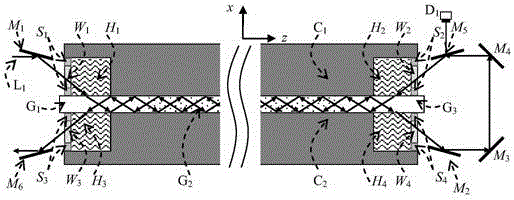

[0089] It is generally believed that the ZigZag optical path can reduce the adverse effects of uneven pump light intensity, temperature and stress in the thickness direction (X) and length direction (Z) of the average slab medium in the ZigZag plane (XOZ plane), and weaken the beam section (XOY section ) in the wavefront distortion in the thickness direction (X) of the slab. The research shows that the ZigZag optical path cannot completely eliminate the thermally induced wavefront distortion in the thickness direction of the slab, and its offset effect on the thermal effect is related to the temperature field distribution in the slab medium and the number of reflections of the laser inside the slab. When the temperature field distribution in the slab medium is determined, with the increase of the number of reflections of the oscillating laser inside the slab medium, the waveform of the thermally induced wavefront distortion transforms between "M" and "W" types (as shown in Figu...

specific Embodiment 2

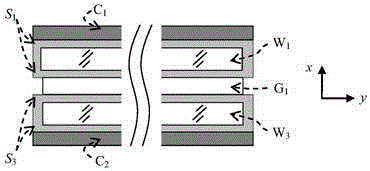

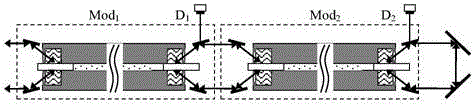

[0125] In the direction perpendicular to the ZigZag optical path (that is, the slab width direction, Y direction), the ZigZag optical path cannot eliminate thermally induced wavefront distortion, which is why the beam quality in the width direction of the slab laser is worse than that in the thickness direction. Further research shows that even if the heat sink is uniformly pumped in the width direction of the slab and the heat sink is uniformly dissipated in the width direction of the slab (the heat dissipation coefficient is a constant value), since the size of the heat sink in the Y direction is larger than that of the slab, It will still cause the center temperature of the slab medium to be high and the edge temperature to be low in the width direction, resulting in wavefront distortion. Therefore, using the combination of side pumping and end pumping, the edge temperature of the slab in the side pumping module is high and the center temperature is low, resulting in a "V"-s...

specific Embodiment 3

[0135] Fig. 6(a) and Fig. 6(b) are the sectional views along the length direction and along the width direction of the slat laser module of Embodiment 3 of the present invention, respectively;

[0136] Fig. 7(a) and Fig. 7(b) are cross-sectional views along the length direction and the width direction of the slat medium according to Embodiment 3 of the present invention, respectively;

[0137] The working principle of specific embodiment 3 is similar to that of specific embodiments 1 and 2, the difference is that in the slab laser module shown in Figure 6 (a), Figure 6 (b), Figure 7 (a), and Figure 7 (b), The laser reflection device includes a first reflection mirror M 1 and rectangular reflectors M 7 ;

[0138] The first mirror M 1 and rectangular reflectors M 7 Placed at both ends of any pair of diagonal corners of the slat medium;

[0139] Incident laser L 1 through the first mirror M 1 Reflected into the slab medium, right-angle reflective prism M 7 Receives the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com