Water cooling valve clack structure of 1500 DEG C ultrahigh-temperature valve

An ultra-high temperature, valve flap technology, used in valve heating/cooling devices, valve details, valve devices, etc., to achieve the effect of improving service life and reducing direct flushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

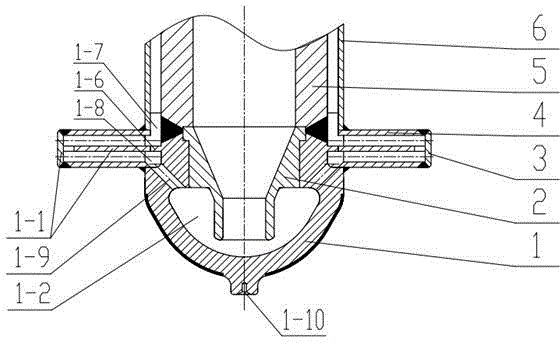

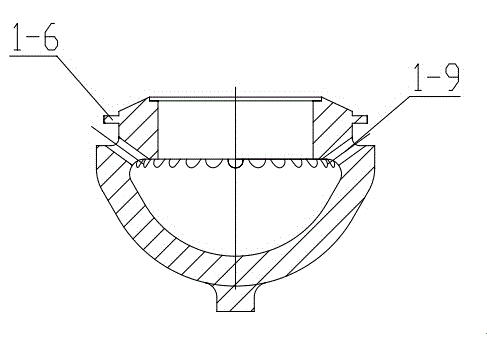

[0020] Such as figure 1 As shown, a water-cooled disc structure for a 1500°C ultra-high temperature valve, including a valve stem and a disc main body, is characterized in that the upper end of the disc main body 1 is sealed and connected to the lug 1-1 through its flange 1-6, The flow channel inlet in the lug communicates with the recess 1-2 in the disc main body 1; the flow channel outlet in the lug connects with the recovery end of the external cooling system, and the recess 1-2 passes through the water-cooled nozzle 2 communicate with the inlet port of the external cooling system.

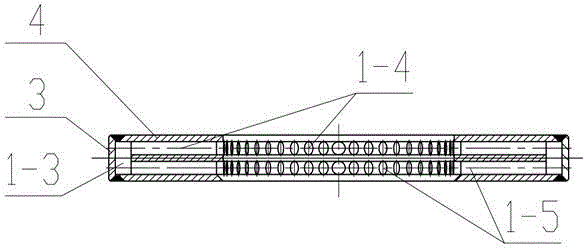

[0021] The lug 1-1 includes an inner ring part 4 and an outer ring part 3, and the inner and outer ring parts are welded and hermetically assembled into one; the outer ring part 3 is made of a heat-conducting material, and a small amount of heat flowing thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com