Gallium oxide nanostructure device, and production method and application thereof

A nanostructure, gallium oxide technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for sensing, etc., can solve the problems of weak response-recovery ability, inaccurate resistance measurement, and influence on detection effect, etc. Sensitive performance, overcoming large resistance, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

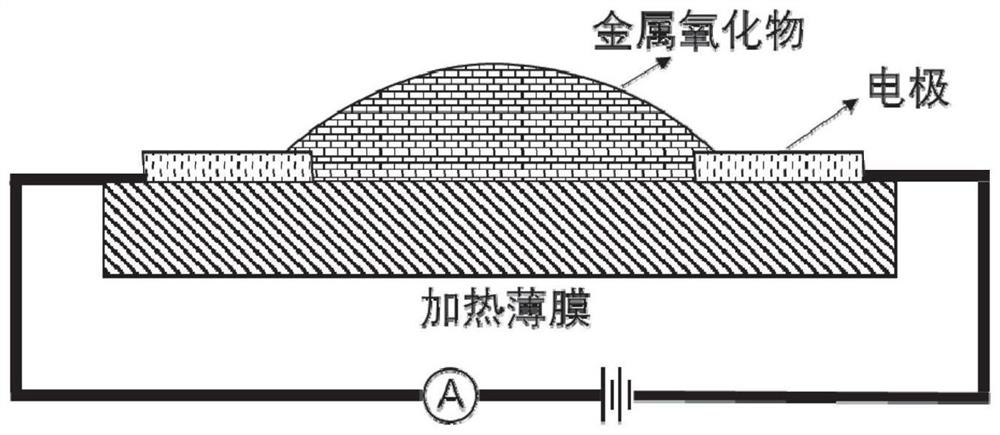

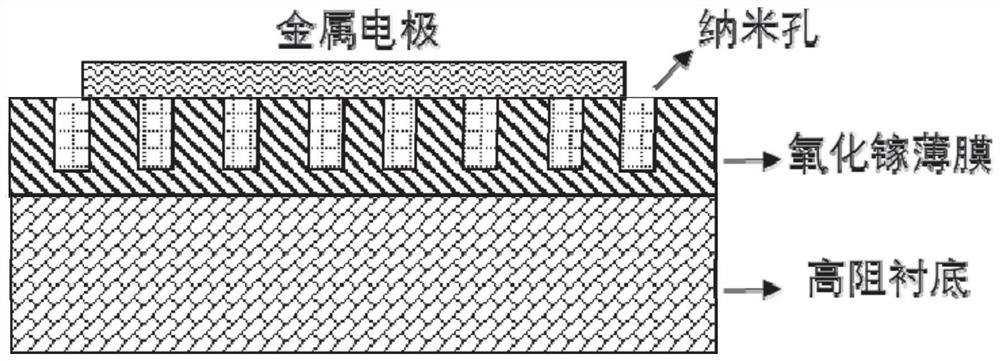

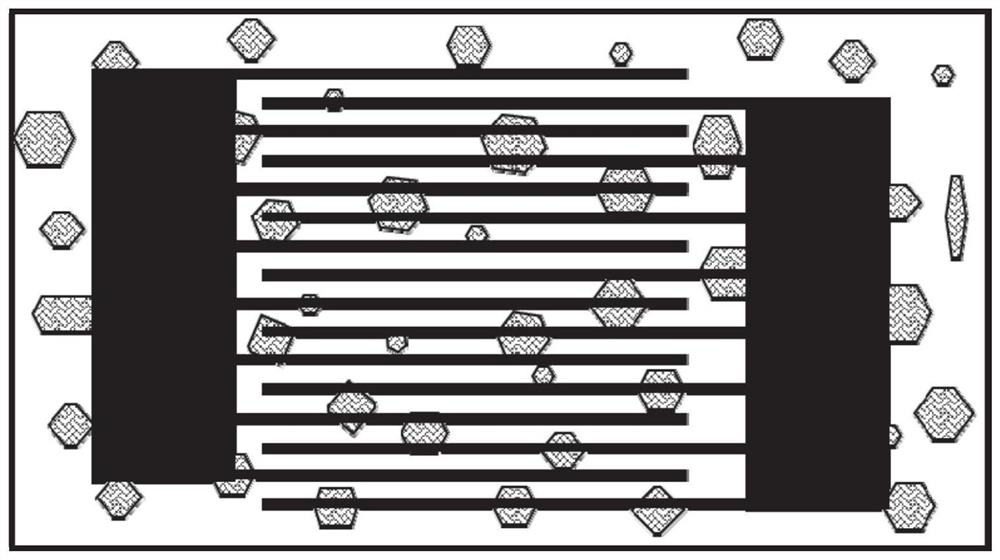

[0077] see image 3 , in a more typical embodiment of the present invention, a preparation method of a gallium oxide nanostructure device may comprise the following steps:

[0078] 1) Epitaxy of gallium oxide thin films: use metal organic compound chemical vapor deposition (MOCVD) or molecular beam epitaxy (MBE) or hydride vapor phase epitaxy (HVPE) on heterogeneous or homogeneous substrates (heterogeneous substrates include but Not limited to sapphire and other materials) to grow gallium oxide thin films, and adjust the n-type doping concentration;

[0079] 2) Metal Ga is etched to form nanopores: Metal organic compound chemical vapor deposition (MOCVD) or molecular beam epitaxy (MBE) or atomic layer deposition (ALD) is used to deposit metal gallium on the surface of gallium oxide film, so that the gallium oxide film Surface corrosion forms a plurality of nanopores of different depths or the same depth; at least one condition in the temperature of deposition, the pressure of...

Embodiment 1

[0088] 1) The metal-organic vapor deposition (MOCVD) process was used to deposit Ga 2 o 3 film growth;

[0089]2) Use high-purity oxygen and triethylgallium (TEGa) as the oxygen source and gallium source respectively, and control the flow rates to 200 sccm and 500 sccm respectively; and use high-purity nitrogen as the carrier gas of TEGa; adjust the temperature in the reaction chamber to 500°C, The pressure is kept at 20KPa, and the growth time is 2 hours to obtain Ga with a thickness of about 10nm-10μm. 2 o 3 film;

[0090] 3) Also use MOCVD equipment to introduce TEGa into the reaction chamber, and control the flow rate of TEGa to 100 sccm, the temperature in the reaction chamber to 500 °C, and pre-deposit Ga droplets on the Ga 2 o 3 On the thin film, the deposition time is 10 minutes; after the pre-deposition is completed, the gallium source supply is stopped, and the temperature in the reaction chamber is raised to 660 °C, Ga droplets and Ga 2 o 3 The film undergoes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com