Technology for coupling utilization and co-processing of organic and inorganic hazardous wastes

A hazardous waste, co-processing technology, applied in the direction of process efficiency improvement, furnace type, combustion type, etc., can solve problems such as insufficient utilization of thermal energy, pollution, unstable combustion process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

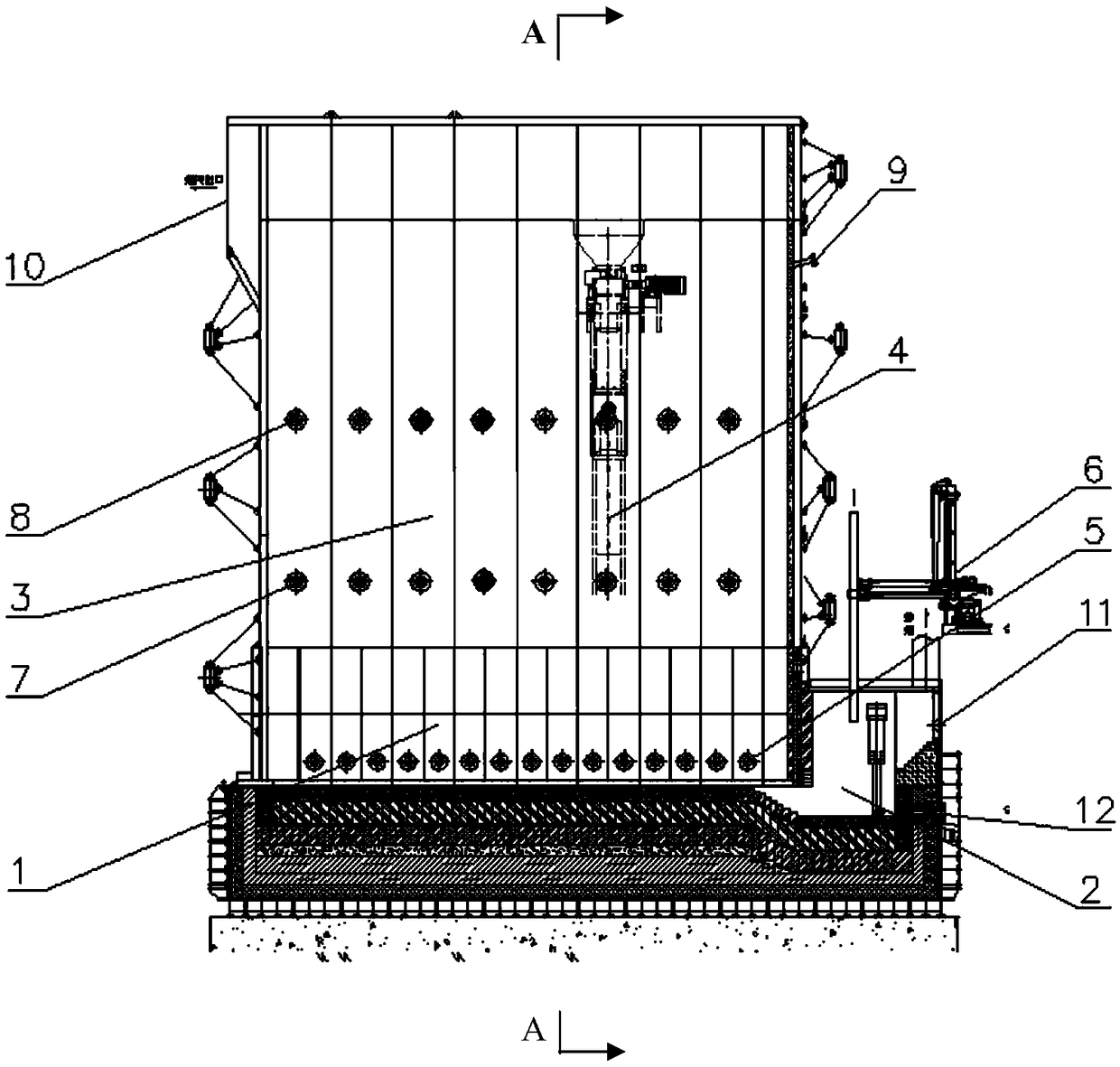

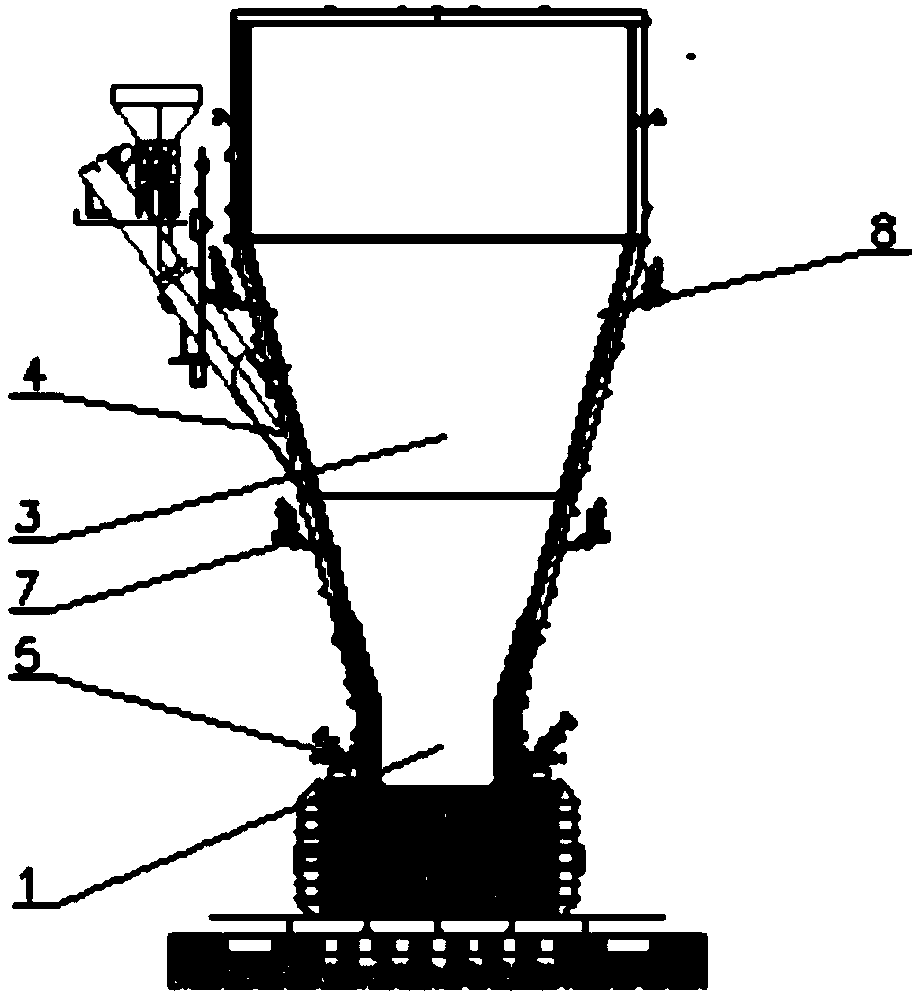

[0037] The hearth area of the smelting furnace of "a process for coupling utilization and co-processing of organic and inorganic hazardous waste" provided by the present invention is 20m 2 , to process 70,000 tons of various inorganic hazardous wastes and 128,000 tons of various organic hazardous wastes annually. Implementation steps:

[0038] (1) Sieve inorganic hazardous waste with a moisture content of ~50% and send it to a disc-type steam dryer for low-temperature drying to reduce the moisture content to below 20% (used by the disc-type steam dryer) The steam comes from the steam produced by the waste heat recovery device supporting the smelting furnace); the inorganic hazardous waste with a moisture content of ≤20% is crushed and screened, and then the screened material and dried inorganic hazardous waste are sent to the mixing room Storage pit for standby;

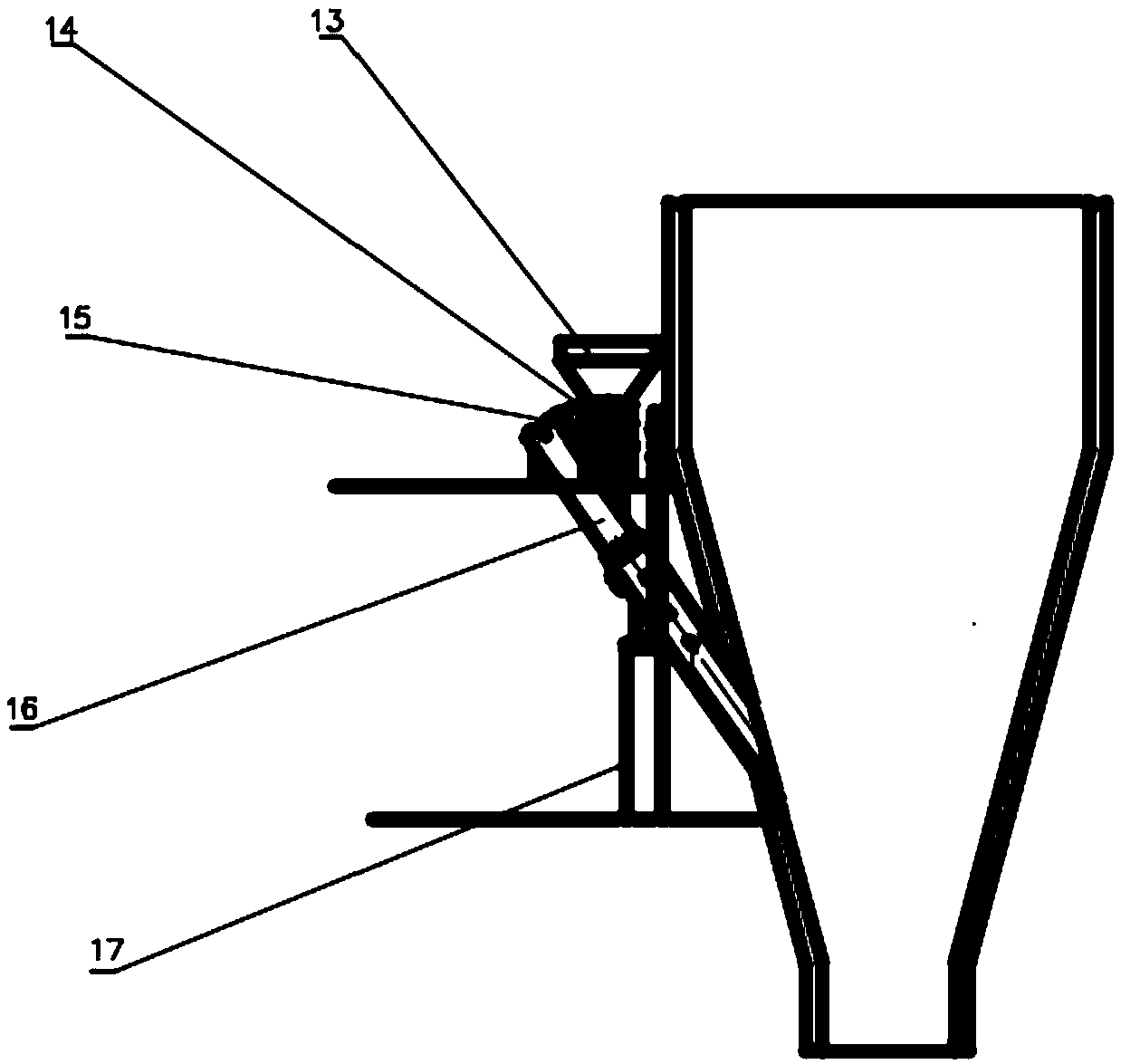

[0039] (2) Use the automatic vacuum packaging machine to vacuum-pack organic hazardous waste, and use the intel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com