Rotor structure for servo motor

A rotor structure and servo motor technology, applied in the field of servo motors, can solve the problems of motor stator and rotor air gap increase, high machining accuracy, waste of magnetic energy, etc., reduce force transmission parts, improve reliability, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

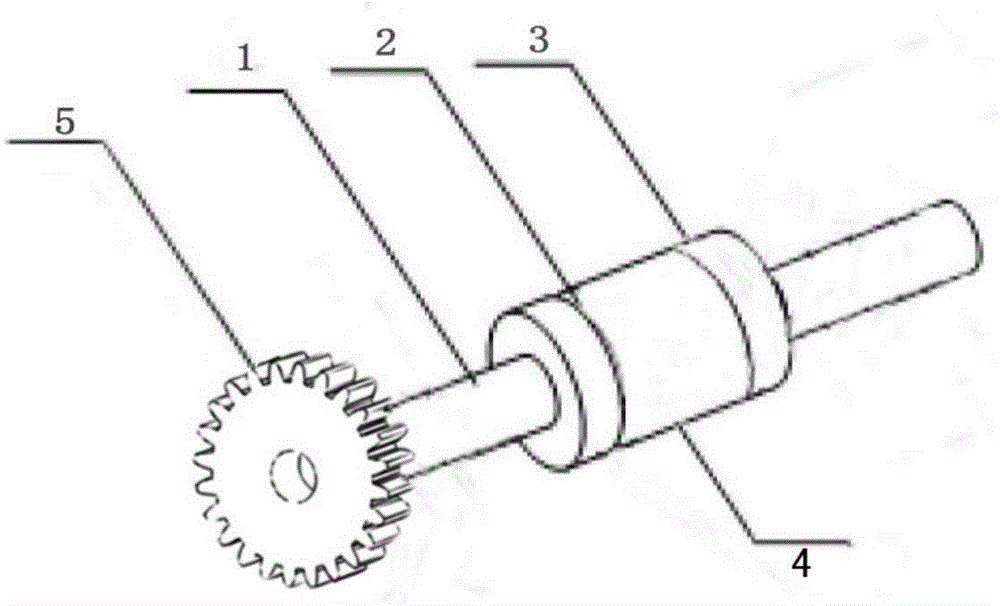

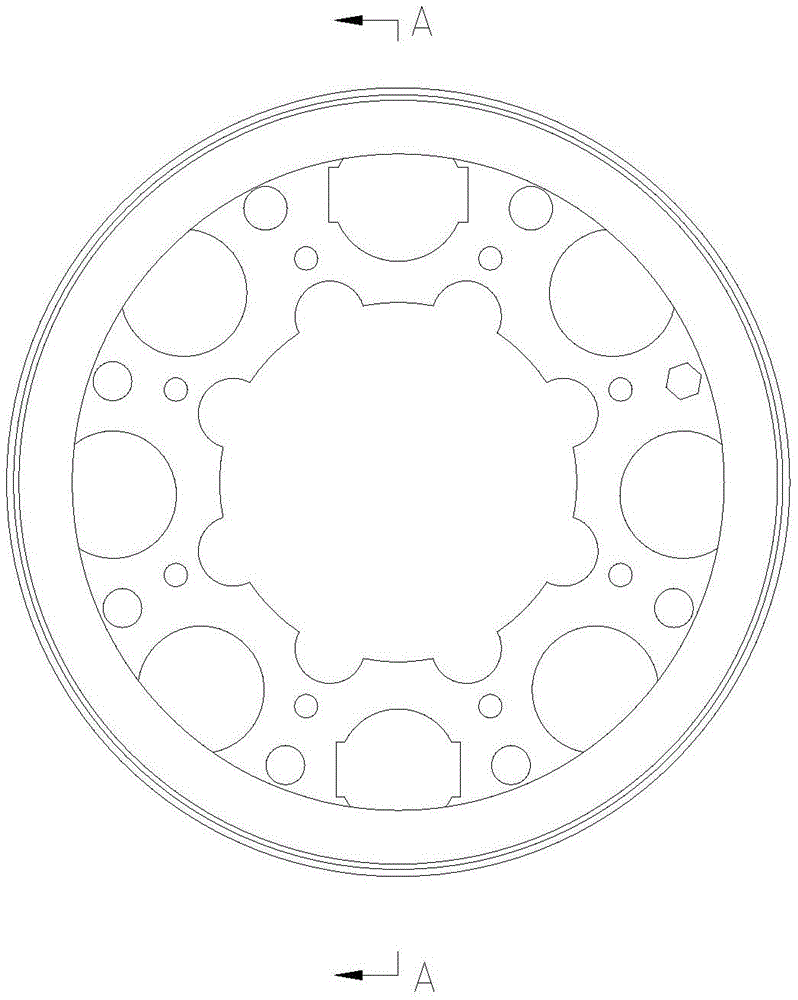

[0015] like figure 1 , figure 2 and image 3 As shown, the rotor structure of the servo motor includes a rotating shaft 1, an iron core 2 arranged on the rotating shaft, a circular permanent magnet 4 fixed around the iron core, and the shaft extension of the rotating shaft has a gear 5; the rotating shaft 1, the rotor core 2, The gears 5 are all made of 316L alloy material with excellent mechanical performance and moderate magnetic permeability, and the ring permanent magnet 4 is made of NdFeB material.

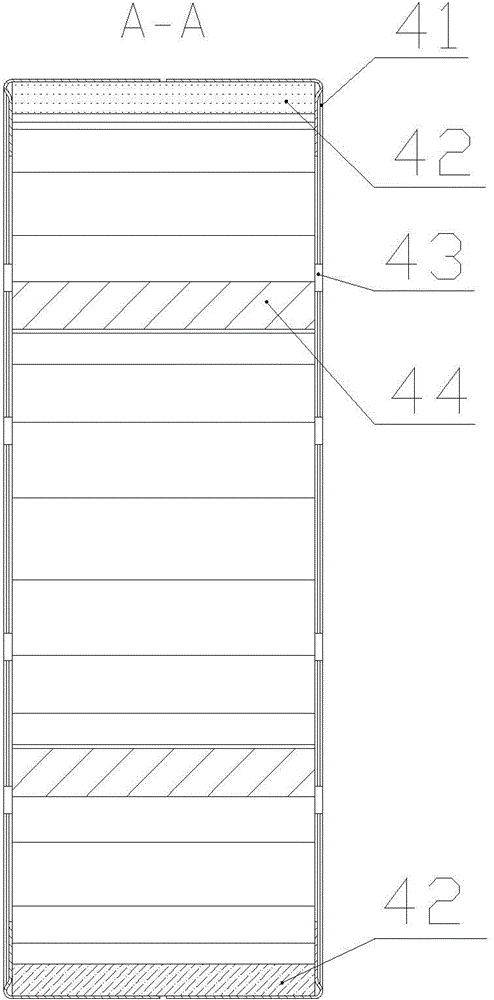

[0016] In this embodiment, the annular permanent magnet 4 is an annular permanent magnet composed of four independent magnets. like figure 2 As shown, the circular ring permanent magnet 4 is respectively provided with a rotor protective cover 41, a magnetic steel 42, a rotor rivet 43, and a silicon steel sheet 44 from outside to inside. The annular permanent magnet 4 is arranged as a cylindrical magnet, which can reduce the production links of the magnet and reduce the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com