Spray cyclone bed type gas liquid solid tri-phase reactor

A gas-liquid-solid, reactor technology, applied in chemical instruments and methods, separation of dispersed particles, chemical/physical processes, etc., can solve the low utilization rate of oxidation air, difficulties in the arrangement of absorption towers, difficulties in sealing the shaft and the wall of the slurry tank, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

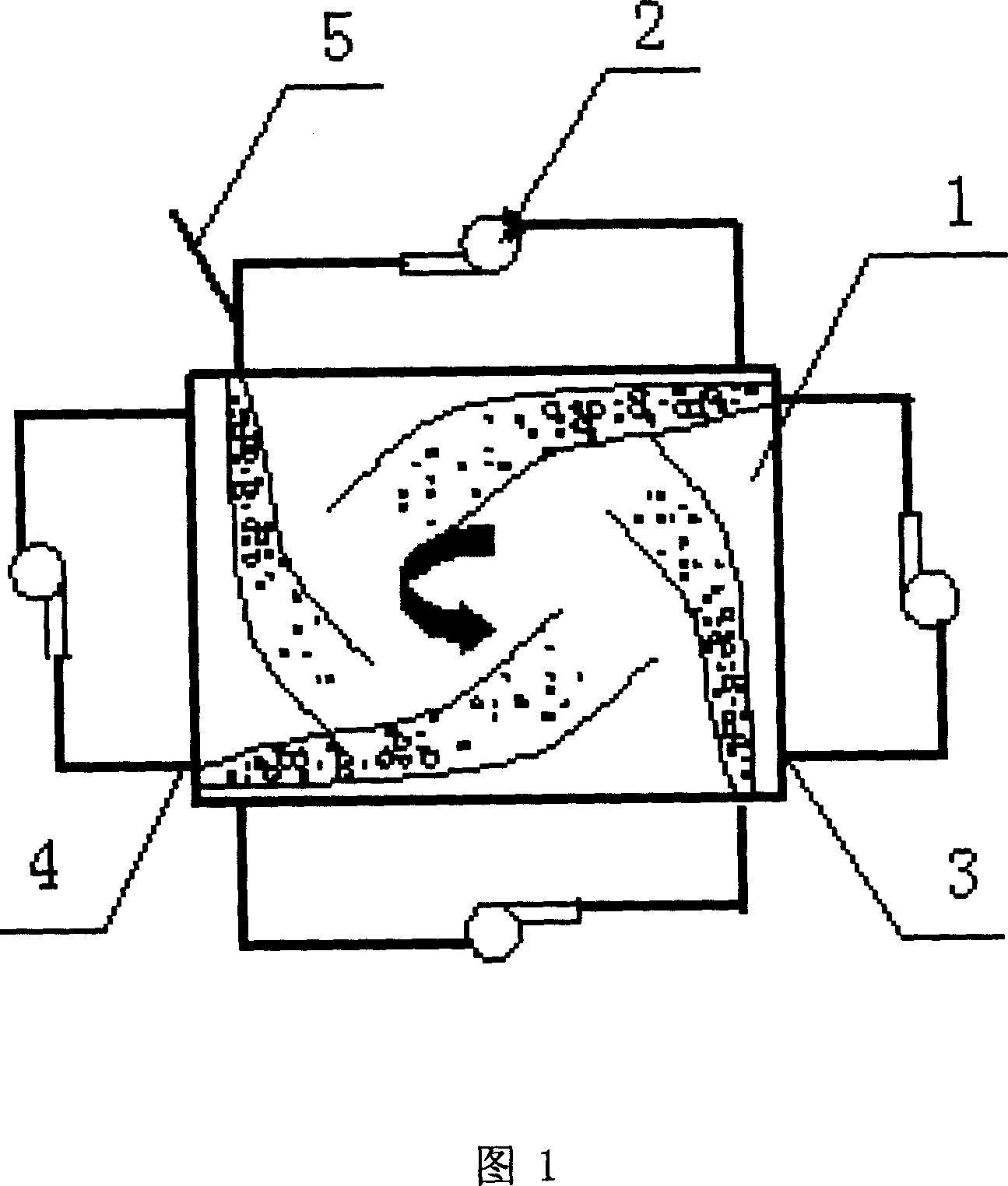

[0011] Referring to Fig. 1, the present invention includes a slurry tank 1, and a slurry circulating pump 2 is respectively arranged on the four walls of the slurry tank 1. When the system is running, the slurry is drawn out from the outlet 3 and sent to the delivery port 4 by the slurry circulating pump 2 for re-use. Enter the slurry pool 1, the cutting angle between the outlet 3 and the delivery port 4 of the slurry pool 1 and the four corners or four walls of the slurry pool 1 is 5°~40°, and it can be placed in the slurry pool 1 after setting according to this angle. The two layers that form the water flow rotate horizontally, so as to realize the turbulent mixing of the gas-liquid two-phase, which is similar to the four-corner tangential combustion in the fire chamber combustion furnace, so as to achieve the expected effect of stirring.

[0012] If the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com