No wall flow technique and equipment for hydrogenation reaction chamber

A hydrogenation reactor and reactor technology, applied in the direction of chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of good sealing performance, simple structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

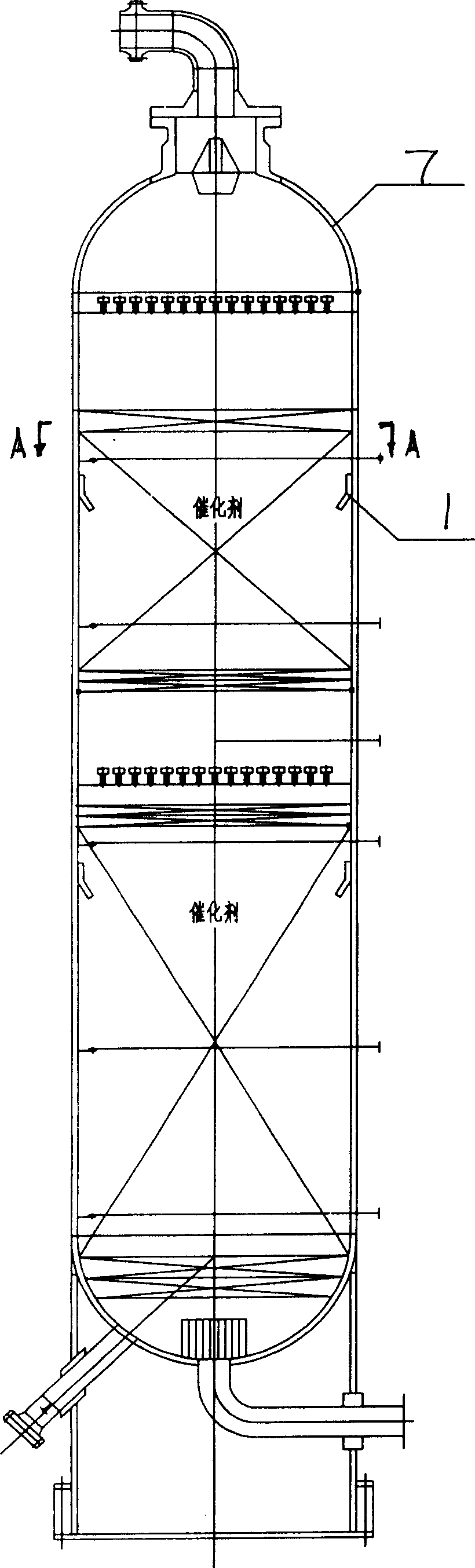

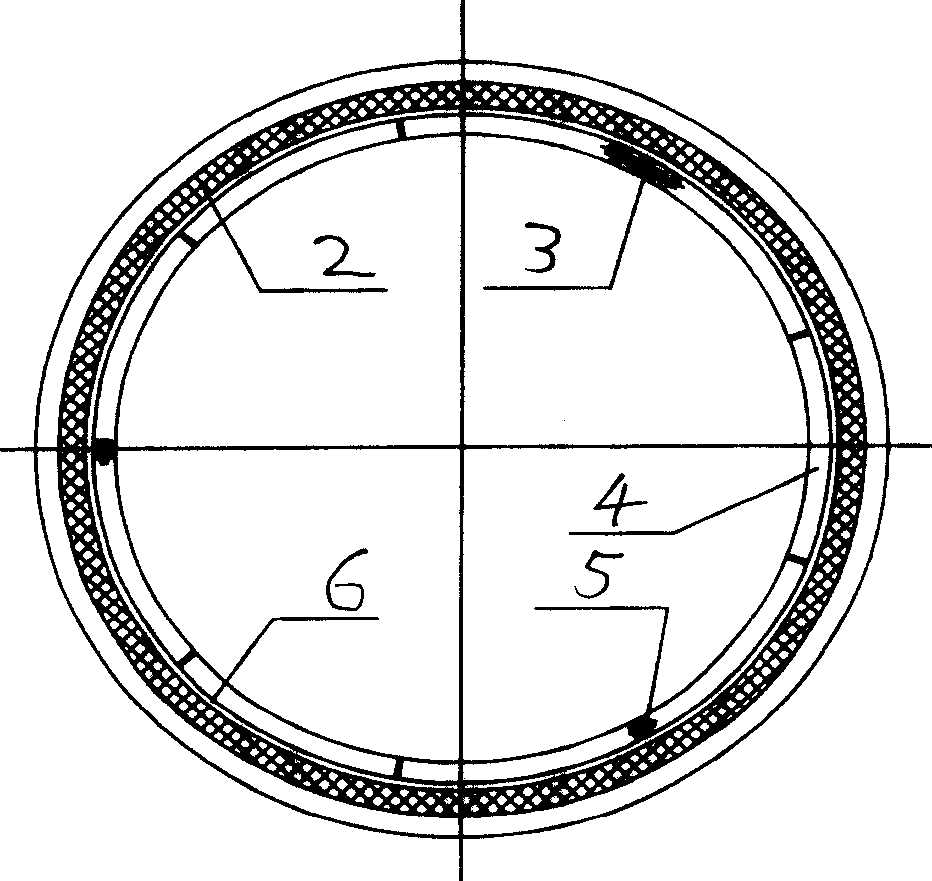

[0035] The application of two reactors in the "200,000 tons / year catalytic cracking gasoline hydro-upgrading unit". The design parameters of the two reactors are as follows:

[0036] One-stage reactor: operating pressure 2.55MPa, operating temperature 430°C, medium gasoline, hydrogen, specification size φ1400×19190×34.

[0037] Second stage reactor: operating pressure 2.65MPa, operating temperature 430°C, medium gasoline, hydrogen, specification size φ2400×16450×54.

[0038] The specific design steps are as follows:

[0039] According to the above parameters, it is calculated by the professional reaction of the process that the gas-liquid two-phase flow characteristics of the two reactors are basically the same during operation, the mass flow rate of the liquid phase flow is greater than that of the gas phase flow, and the flow rate between each bed of the catalyst The gas-liquid two-phase flow velocity is small, and the liquid phase flow ρv 2 =210~260kg / (m.s 2 ), gas phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com