Method for producing ferrochromium alloy by two-step-process smelting reduction of ferrochromium mineral powder

A technology of chromite powder and ferrochrome alloy, which is applied in the field of non-blast furnace ironmaking, can solve the problems of production capacity and equipment size matching, large floor space, low thermal efficiency, etc., and achieve low production cost, energy saving, and high metallization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

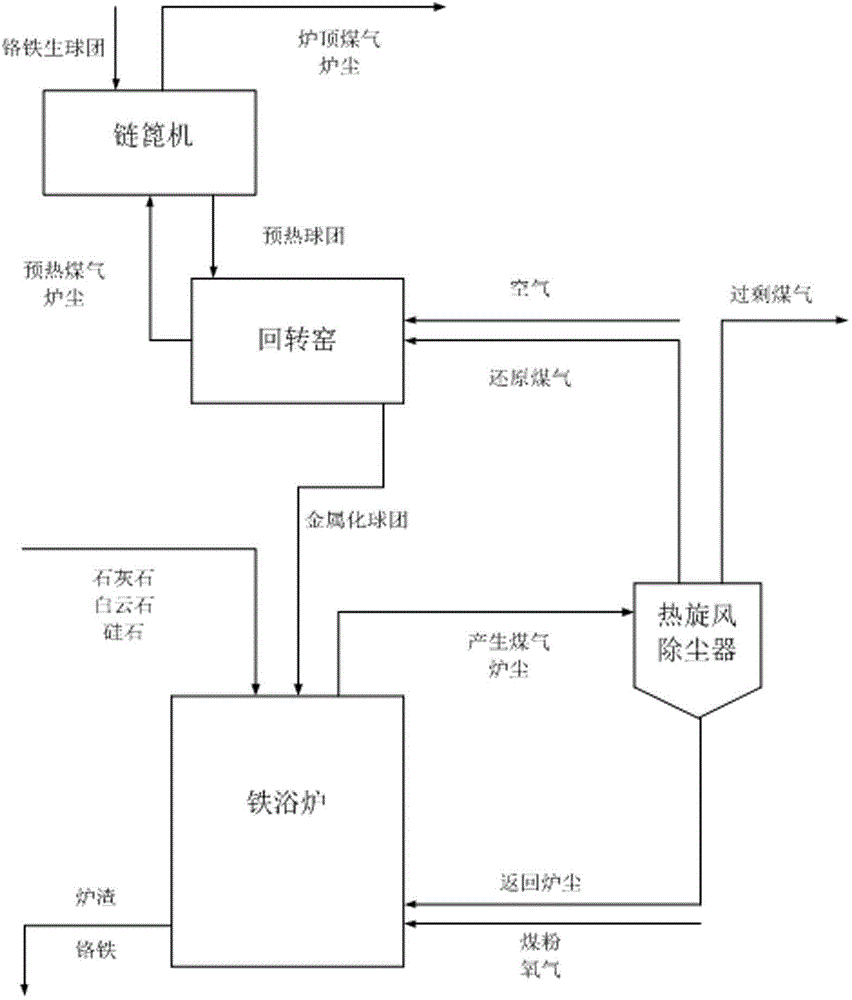

[0018] The present invention will be further described below in conjunction with the accompanying drawings. It should be understood that the specific embodiments are only to further illustrate the present invention, but do not constitute a limitation to the present invention.

[0019] (1) Raw material preparation: Mix chromite powder, coke powder, bentonite, and water and make pellets on the pelletizer, wherein: the amount of coke powder added is determined by the carbon-oxygen ratio of the green pellets being 1:1, and the amount of bentonite added It is 3% of the mass of chromite powder, the amount of water added is 5% of the mass of chromite powder, and the pellet diameter is 20mm.

[0020] (2) Preheating and drying: Spread the raw balls evenly on the grate plate of the slow-moving grate, and use the hot air flow discharged from the kiln tail of the rotary kiln to dry and preheat the raw balls. Next, the carbon-containing green pellets pass through the blast drying section,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com