Clean and effective preparation of oligoxylose

A xylooligosaccharide, clean technology, applied in the direction of oligosaccharides, fermentation, etc., can solve the problems of sewage, low efficiency, and many chemical procedures, and achieve the effect of strong production capacity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

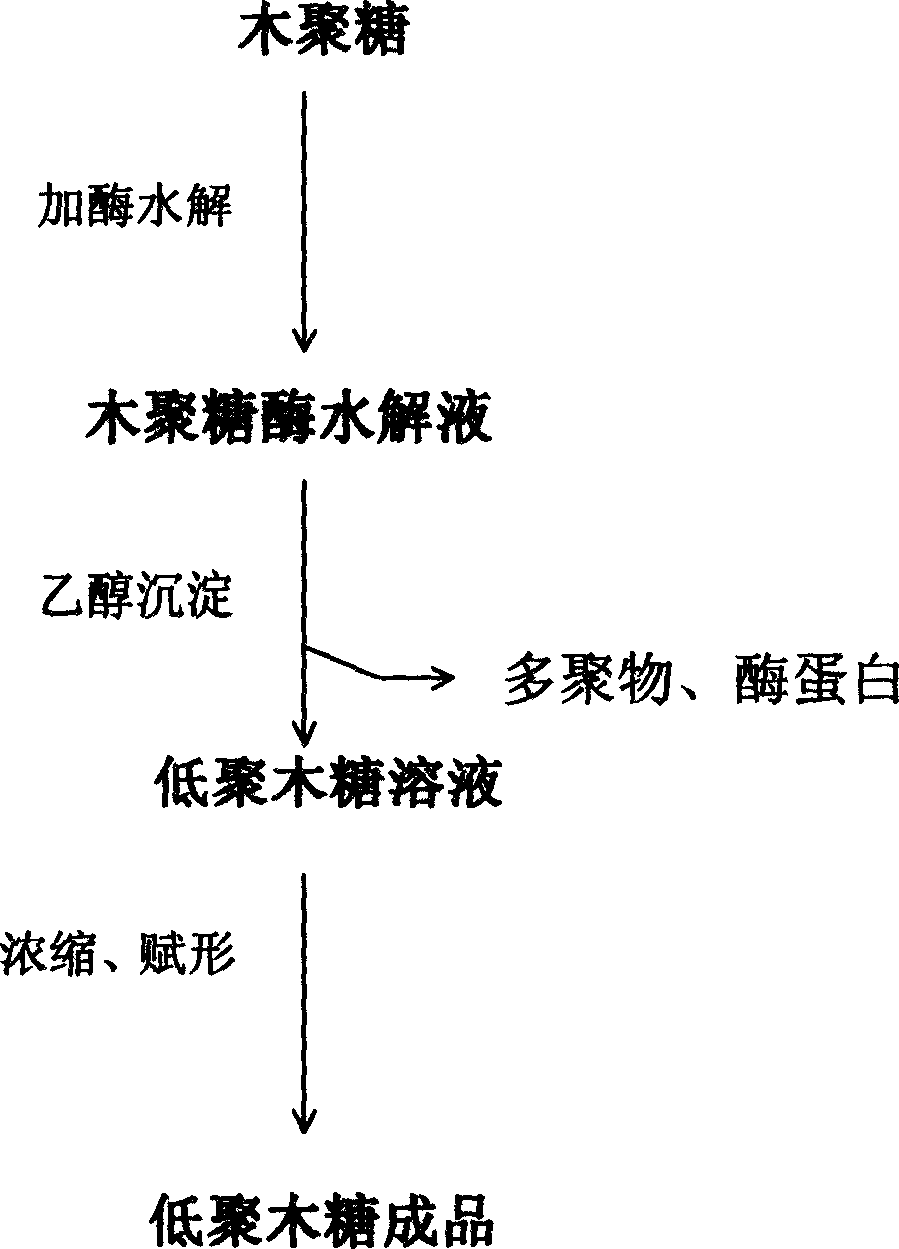

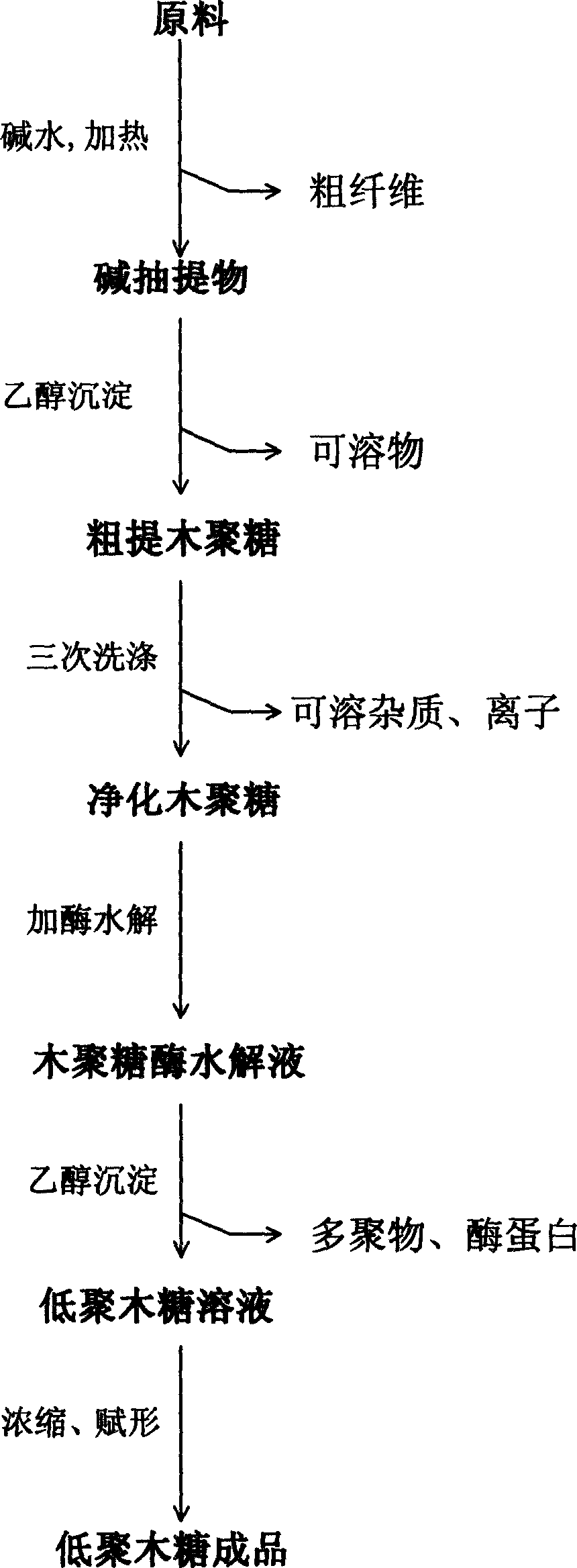

Method used

Image

Examples

Embodiment 1

[0041] (1) Shake the non-mildew straw to remove dust and dry it and grind it into 1-20mm long shredded grass;

[0042] (2) Weigh 10 kg of grass silk, add 2.5% KOH solution 501, cook for 15 minutes after soaking for 4 hours, and extrude the solution; add 2.5% KOH solution 201 to the grass dregs, cook for 15 minutes again, and extrude solution. Combine the two parts of the extrudate, and centrifuge with a continuous flow centrifuge to obtain about 50 l of the supernatant;

[0043] (3) Add 150L of 95% ethanol, adjust the pH value to 6.0 with phosphoric acid after mixing, and collect the precipitated crude xylan by centrifugation;

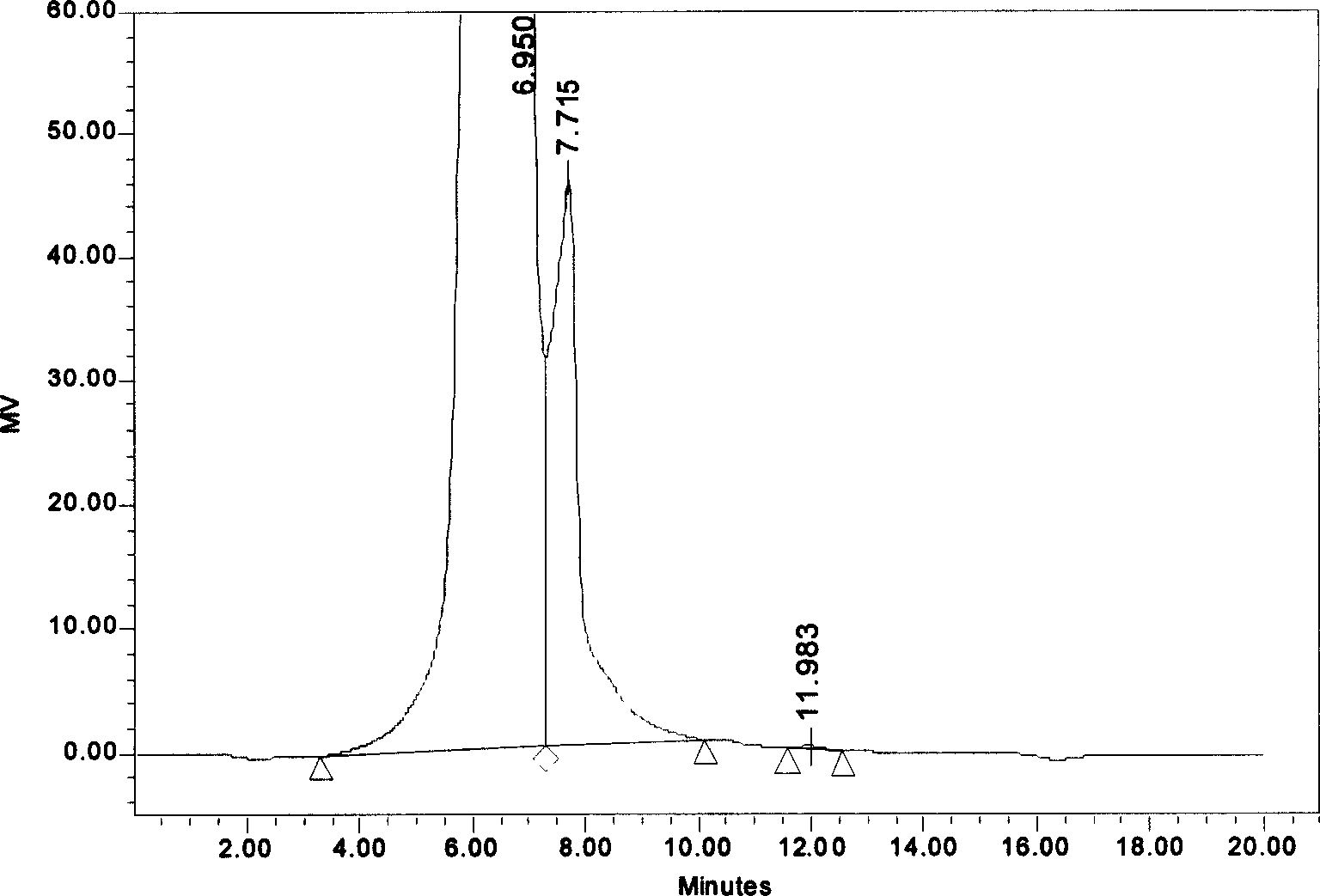

[0044] (4) Add 95% ethanol 501 to the coarsely extracted xylan precipitate, break it and stir at low speed for 2 hours to fully balance it, and collect the precipitate by centrifugation; add ethanol and repeat the aforementioned process twice to obtain purified xylan sugar, (see image 3 )HPLC analysis column: Sugarpak1; 6.5mm×300mm sugar column ana...

Embodiment 2

[0048] Embodiment 2: It is basically the same as Embodiment 1, except that the xylan was purchased from Sigma Company of the United States, and the product number is x0627. Dissolve xylan in citric acid buffer to prepare a xylan solution with a concentration of 30%.

Embodiment 3

[0049] Embodiment 3: substantially the same as embodiment 1, the difference is that xylan is prepared by the following method:

[0050] Extract xylan from corncobs with 2% NaOH solution; add 3 times the volume of ethanol with a concentration of about 95% to the alkali extract to precipitate xylan, and centrifuge to separate the precipitate; Dissolve in water, add 3 times the volume of ethanol to precipitate xylan, and collect the precipitate by centrifugation; repeat twice to obtain purified xylan. Dissolve xylan in citric acid buffer to prepare a 20% xylan solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com