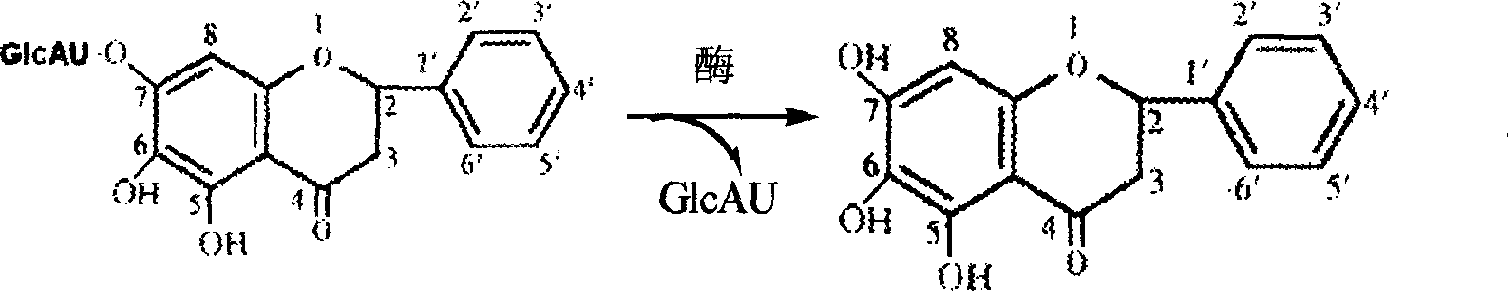

Preparation of scutellarin from scullcaposide glucuronyl by enzyme hydrolysis

A technology of baicalin and glucose, which is applied in the field of enzymatic hydrolysis of glucuronic acid groups of baicalin, which can solve the problems of large damage to baicalin and environmental pollution, and achieve the effects of increasing conversion rate, increasing enzyme production, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] a. Take thermoaerobic bacteria Bacillus sp.JF 2 Bacteria (document 8) were shaken and cultured at 60°C for 30-90 hours in a medium containing 3% corn flour and 0.05% enzyme-producing inducer-baicalin, and were centrifuged to remove bacteria and impurities to obtain an enzyme-containing mixture. solution, add 65% saturated ammonium sulfate to the enzyme mixture to precipitate the enzyme protein, dialyze with 0.02M, pH5 acetate buffer, centrifuge to remove impurities, and freeze-dry to obtain baicalinase.

[0022] b. Mix 0.2 grams of the above-mentioned baicalin enzyme, 3 grams of baicalin, and 150 milliliters of acetic acid buffer (0.2M, pH5.0) so that the concentration of baicalin is 0.01 to 15%, and stir the reaction at a temperature of 70°C 1 to 24 hours.

[0023] c. After the reaction, 300 ml of ethanol was added to precipitate the enzyme protein, the protein precipitate was removed by filtration, and the filtrate was evaporated to dryness under reduced pressure to ...

Embodiment 2

[0025] a. Use high-temperature anaerobic bacteria Clostridium thermocopriea JT3-4 (document 9) in the medium containing 4% corn flour and 0.4% soybean extract, under the condition of temperature 60 ℃, anaerobic stirring culture for 30 to 90 hours, centrifuged to remove bacterium to obtain an enzyme-containing mixed solution, adding ethanol to the enzyme-containing mixed solution to precipitate the enzyme protein, and freeze-drying to obtain baicalinase.

[0026] b. 3 grams of the above-mentioned baicalinase, 2 grams of baicalin, and 120 milliliters of phosphate buffer (0.2M, pH5.0) were mixed evenly so that the concentration of baicalin was 0.01-15%, and the reaction was stirred at a temperature of 60°C for 0.5- 20 hours.

[0027] c. After the reaction, 300 ml of ethanol was added to precipitate the enzyme protein, the protein precipitate was removed by filtration, and the filtrate was evaporated to dryness under reduced pressure to obtain 1.7 g of crude product. Dissolving i...

Embodiment 3

[0029] a. Use Aspegillus niger in a culture medium containing 4% malt extract and 0.5% enzyme-producing inducer—Scutellaria baicalensis extract, stir at a temperature of 28-30°C, and cultivate in ventilation for 50-100 hours , sterilize by centrifugation, use 60-75% saturated ammonium sulfate to precipitate enzyme protein, collect protein, dissolve in acetic acid buffer (0.02M, pH5.0) of 1 / 10 fermentation broth volume, dialyze to remove ammonium sulfate, centrifuge Slag removal is the baicalin enzyme liquid.

[0030] b. Mix 3 grams of baicalin, 100 ml of acetic acid buffer (0.02M, pH 5.0) and 20 ml of the above-mentioned baicalin enzyme solution to make the concentration of baicalin 0.01-15%, and react at 20-55°C for 2-16 Hour.

[0031] c. adding 1 / 2 volume of n-butanol for extraction four times, and evaporating to dryness under reduced pressure to obtain 2 grams of crude baicalein. The conversion rate of baicalein was determined to be 85% by high-performance liquid chromato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com