Method for sifting and cultivating bacillus thuringiensis of high-yield thermostable proteinase

A technique for screening Bacillus aureus and a screening method, which is applied in the field of screening and culturing high-yield, high-temperature resistant protease Bacillus thuringiensis, which can solve the problems of heavy workload and long cycle, and achieve the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

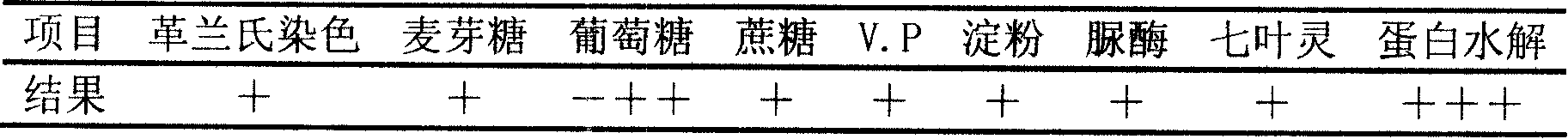

[0039] Embodiment one: a kind of Bacillus thuringiensis screening method of high-yielding thermostable protease comprises the following steps:

[0040] Production of the casein substrate agar identification plate: the agar identification plate formula (weight percentage) is 2% casein, 2% agar, the rest is water, pH is 7.0-7.2, and is prepared into an agar plate with a thickness of 3mm.

[0041] Primary screening 1: Separating 34 strains of Bt strains on a flat plate, after the growth of sparse small colonies, use a puncher to take out a small piece of agar with a single colony, take 3 agar pieces for each strain, and place the 34 agar pieces in the On the same identification plate, a total of three identification plates were placed at 37 ° C for 24 hours. According to the large proteolytic circle formed around the agar block, the strain with high transparency was a high-yielding strain.

[0042] Preliminary screening 2: use a hole puncher to punch 34 holes of 1.5 mm in size on...

Embodiment 2

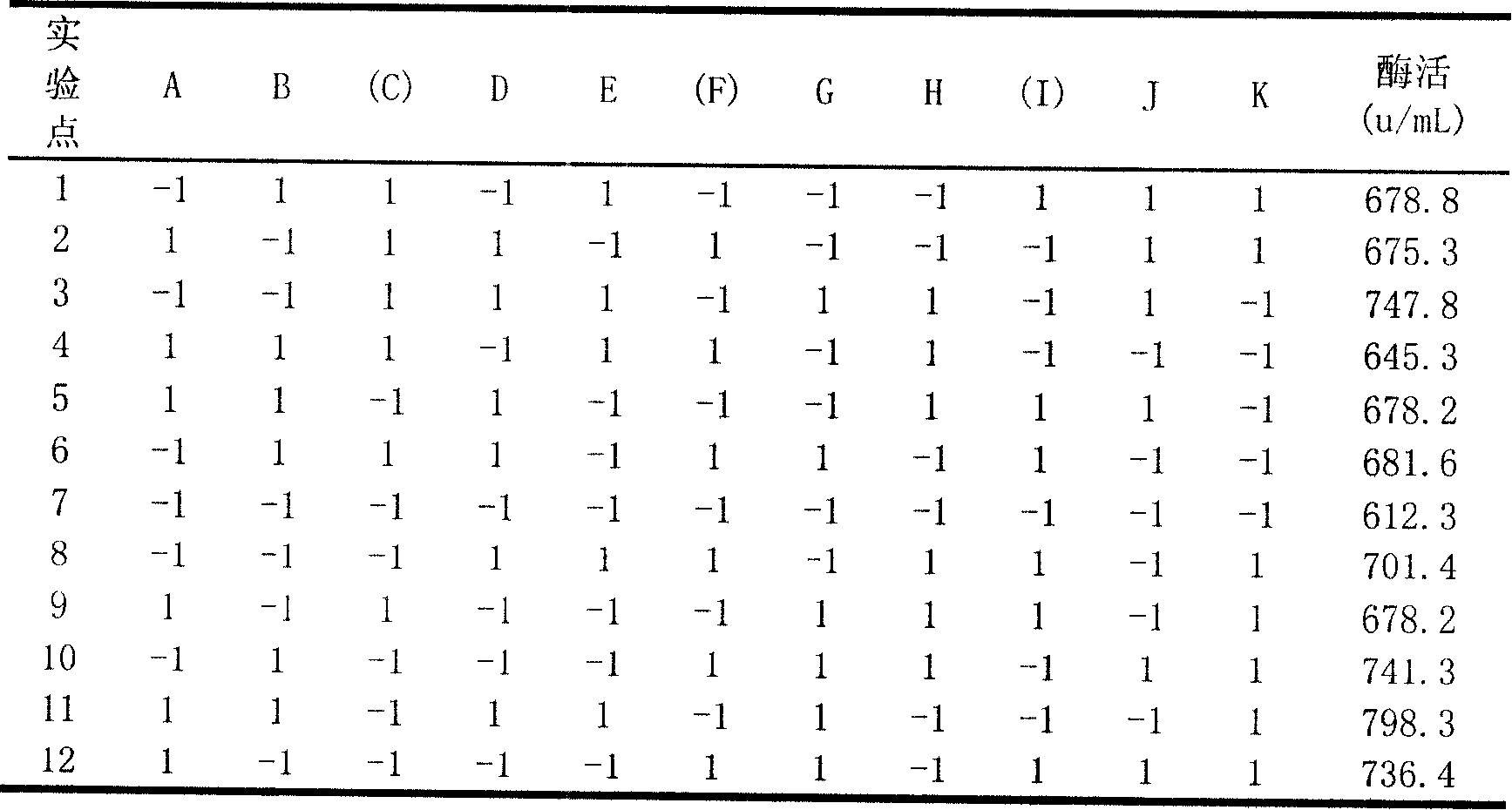

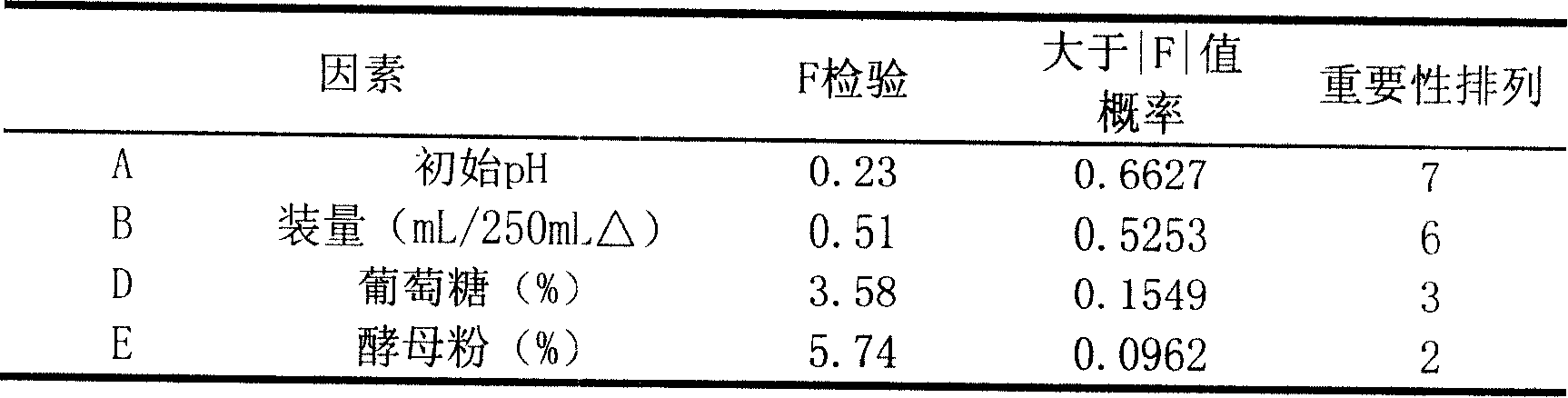

[0045]Embodiment two: Bt140 produces enzyme fermented liquid preparation

[0046] Bt140 fermentation broth preparation, including strain selection, slant culture, primary seeds, slant medium is beef extract peptone medium. The Bt140 slant culture was placed at 37°C, and after 2 days of culture, it was stored in a refrigerator at 4°C. Connect a loop from the inclined plane to a 250mL Erlenmeyer flask, the medium capacity is 35mL / 250mL Erlenmeyer flask, the medium is beef extract peptone, under the condition of 31°C, place it on a shaker at 250r / min, cultivate it for 15h, and obtain a grade seeds. By counting the primary seeds, the inoculum size of the controlled fermentation was 0.75mL (bacteria suspension concentration 7×10 6 Individual / mL), the fermentation medium formula (percentage by weight) is: soybean cake powder 1.8%, yeast powder 0.36%, glucose 0.14%, KH 2 PO 4 0.25%, MgSO 4 ·7H 2 O 0.035%, CaCO 3 0.05%, the rest is water. The culture conditions for fermentati...

Embodiment 3

[0047] Embodiment three: Utilize Bt140 to produce enzyme fermented liquid to prepare thermostable protease and Bt insecticide

[0048] 1. Preparation of Bt insecticide: Take 1000L of Bt140 enzyme-producing fermentation broth as described in Example 1, adjust the pH to 5.0, and add flocculant Al in a ratio of 3% under stirring at 50r / min 2 (SO 4 ) 3 .18H 2 030kg, after precipitation 2h, adopt butterfly centrifuge, centrifuge speed is 8000r / min, centrifugal operation 15-20min, carry out bacterial liquid separation, obtain wet thalline and remove the enzyme-producing fermented liquid after thalline. The wet bacteria were collected and vacuum-dried for 8 hours, and crushed to obtain Bt insecticide; the enzyme-producing fermentation liquid after removing the bacteria was used to prepare high-temperature-resistant protease.

[0049] 2. Preparation of food-grade high-temperature-resistant protease: take 1000L of the enzyme-producing fermentation liquid after removing the bacteria,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com