Acetaldehyde dehydrogenase and application thereof in aspect of anti-alcoholic health-care products

An acetaldehyde dehydrogenase and product technology, applied in the field of enzyme engineering, can solve problems such as unsuitable food preparation, and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Synthesize the ALDH2 gene shown in SEQ ID NO.1; activate and culture Bacillus subtilis 168, inoculate in LB medium, and extract plasmid pMA5 after culturing for 18-24 hours. The ALDH2 gene and pMA5 were digested and ligated to construct the recombinant plasmid pMA5-aldh2; the recombinant plasmid pMA5-aldh2 was transformed into Bacillus subtilis 168 competent cells, cultured in LB medium, spread on LB plates, and challenged Take positive clones, extract plasmids and verify by sequencing. The strains with correct sequencing are recombinant bacteria.

Embodiment 2

[0018] The recombinant Bacillus subtilis prepared in Example 1 was inoculated in LB medium, activated at 37°C, and then the two bacterial solutions were simultaneously transferred to fresh LB medium for cultivation. The specific operation steps are as follows:

[0019] (1) Activation of bacteria

[0020] Take 30 μL of the original bacteria and integrated bacteria stored in glycerol tubes and add them into 10 mL test tubes containing LB medium, and culture them at 37°C and 200 rpm for 14-20 hours to obtain seed liquid.

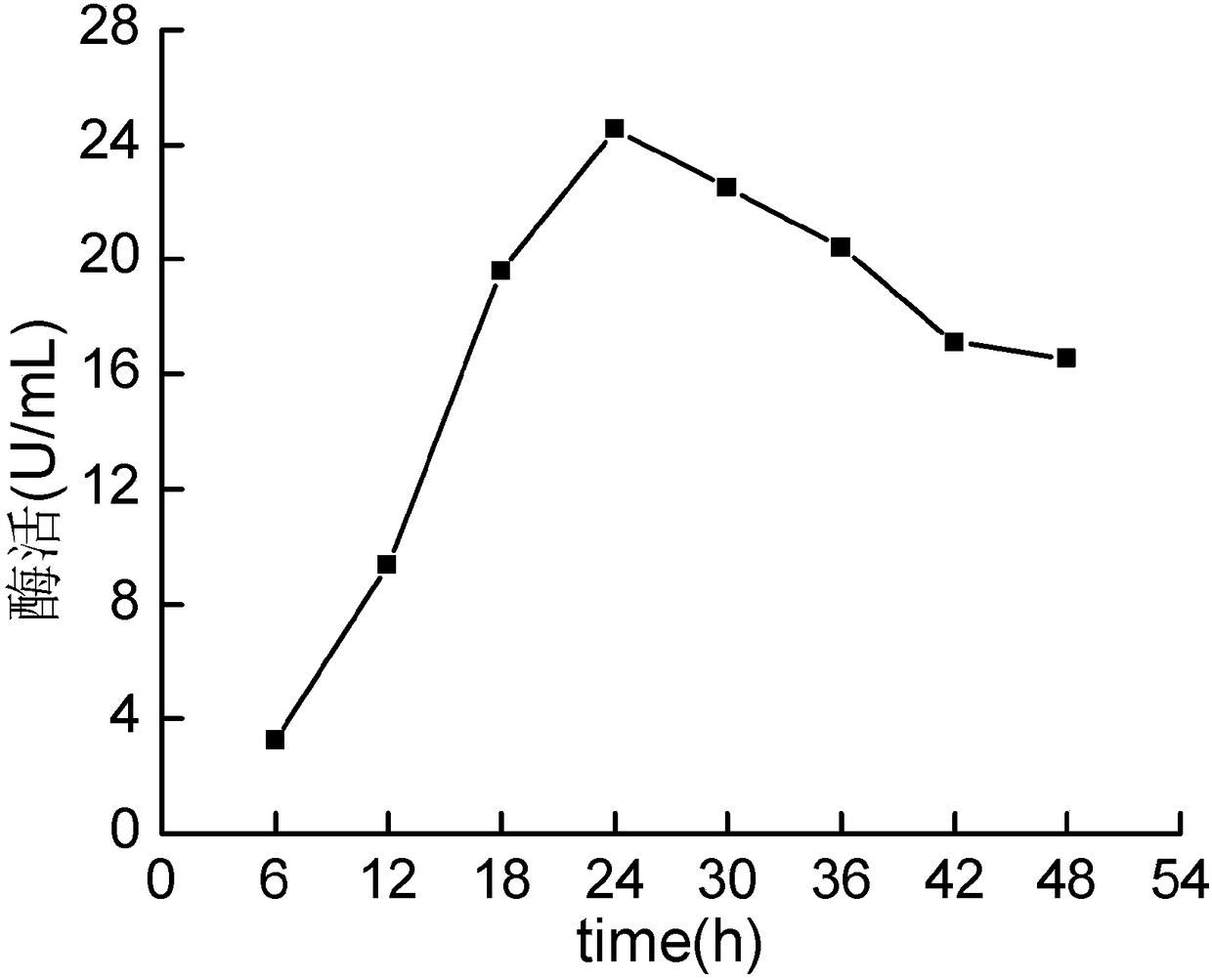

[0021] (2) Strain fermentation

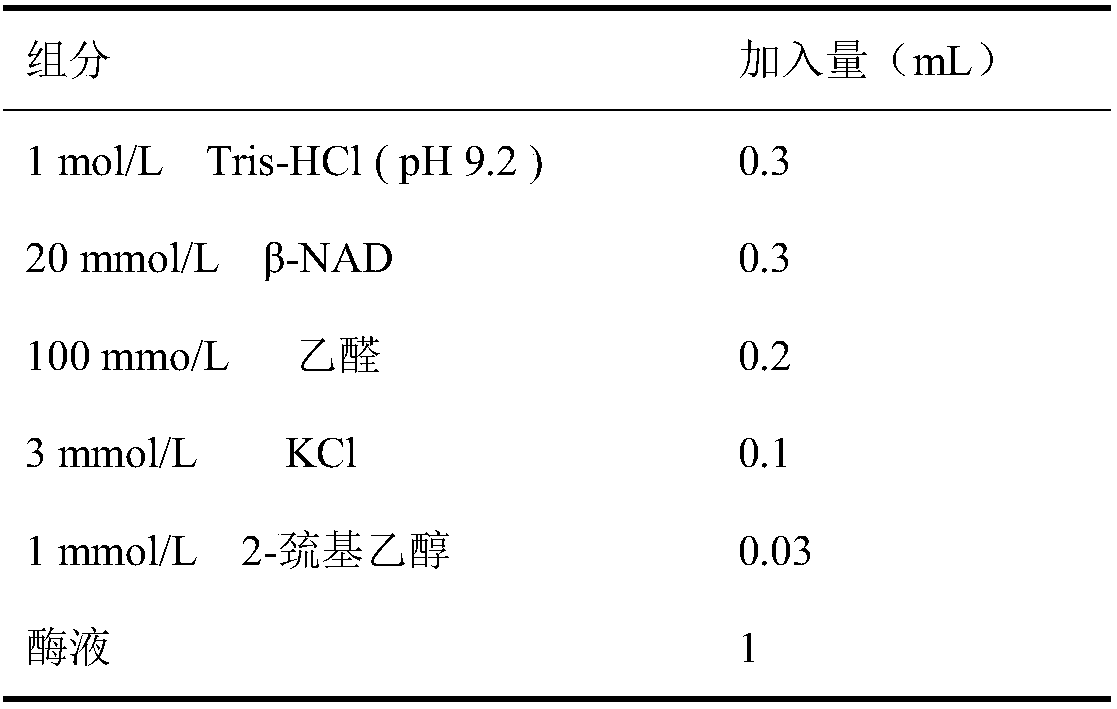

[0022] Take 2 mL of the activated seed solution and add it to 200 mL of LB medium, and ferment for a period of time under the conditions of 37 ° C and 200 rpm, and take 5 mL of fermentation liquid for the determination of specific activity at 24 h, 30 h, 34 h and 48 h of fermentation.

[0023] (3) Treatment of fermentation broth

[0024] Centrifuge 5mL of the fermentation broth at 8000rpm for 5min, wash the cells once with ste...

Embodiment 3

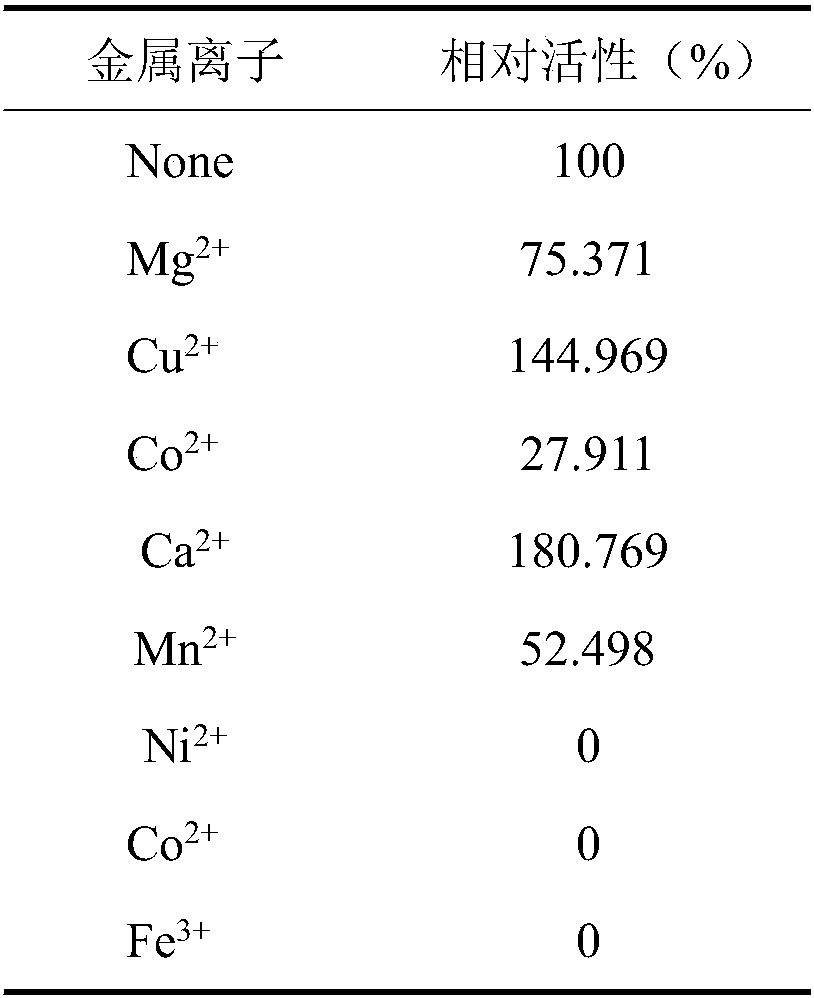

[0031] The bacterial strain was cultivated in the same manner as in Example 2, except that 0.4 mmol / L metal salt (Table 2) was added to the culture medium. Enzyme activity was measured after 24 h of fermentation. The enzyme activity of fermenting 24h under the identical conditions of embodiment 2 is 100%, and the result is as shown in table 2, adding Ca 2+ Salt and Cu 2+ Salt can increase the production of enzymes in the fermentation broth to a certain extent. Due to Ca 2+ Salt and Cu 2+ The metal ion is harmless or even beneficial to the human body, and has important application significance for preparing products containing acetaldehyde dehydrogenase in the food field.

[0032] Table 2 Changes of enzyme activity in a unit of fermentation broth containing different metal ions

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com