Preparation method of hydrolyzed whey protein cross-linked product

A technology of hydrolyzed whey protein and whey protein isolate, which is applied in the field of preparation of hydrolyzed whey protein cross-linked products, can solve the problems of lack of stable interface, unpleasant flavor and bitter taste, etc., and achieves product safety, high thermal stability and high appearance. The effect of apparent viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

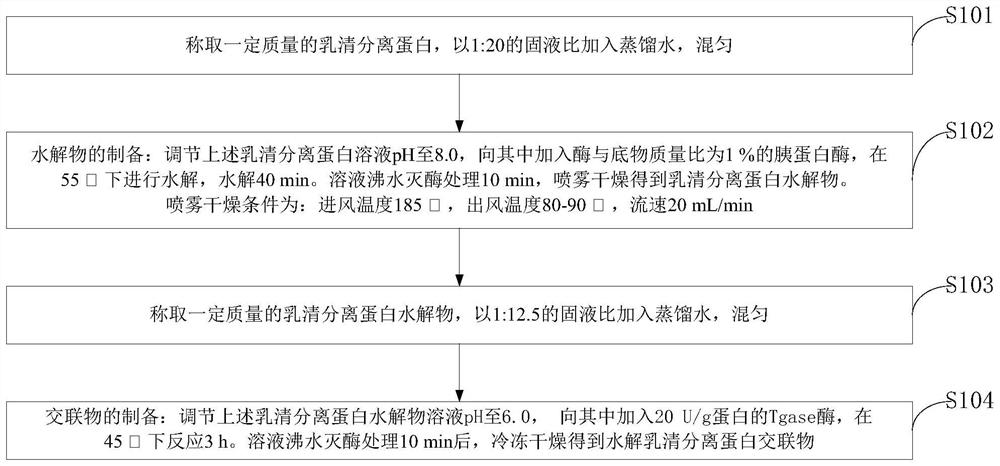

[0036] Such as figure 1 As shown, the method for preparing hydrolyzed whey protein cross-linked product provided by the embodiment of the present invention comprises:

[0037] S101, weigh a certain amount of whey protein isolate, add distilled water at a solid-to-liquid ratio of 1:20, and mix well.

[0038] S102, preparation of hydrolyzate: adjust the pH of the whey protein isolate solution to 8.0, add trypsin with a mass ratio of enzyme to substrate of 1%, and perform hydrolysis at 55° C. for 40 minutes. The solution was treated with boiling water to inactivate enzymes for 10 minutes, and spray-dried to obtain whey protein isolate hydrolyzate. The spray drying conditions are: air inlet temperature 185°C, air outlet temperature 80-90°C, flow rate 20mL / min.

[0039] S103, weigh a certain amount of whey protein isolate hydrolyzate, add distilled water at a solid-to-liquid ratio of 1:12.5, and mix well.

[0040] S104, preparation of the cross-linked product: adjust the pH of the...

Embodiment 2

[0045] The method for preparing hydrolyzed whey protein cross-linked product provided by the embodiment of the present invention comprises:

[0046] 1. Weigh a certain amount of whey protein isolate, add distilled water at a solid-to-liquid ratio of 1:10, and mix well.

[0047] 2. Preparation of hydrolyzate: adjust the pH of the whey protein isolate solution to 7.0, add trypsin with a mass ratio of enzyme to substrate of 0.5% (w / w) therein, and perform hydrolysis at 45°C. Hydrolyzed for 10min. The solution was treated with boiling water to inactivate enzymes for 10 minutes, and spray-dried to obtain whey protein isolate hydrolyzate. The spray drying conditions are: air inlet temperature 185°C, air outlet temperature 80-90°C, flow rate 20mL / min.

[0048] 3. Weigh a certain amount of whey protein isolate hydrolyzate, add distilled water at a solid-to-liquid ratio of 1:20, and mix well.

[0049] 4. Preparation of cross-linked product: adjust the pH of the whey protein isolate ...

Embodiment 3

[0051] The method for preparing hydrolyzed whey protein cross-linked product provided by the embodiment of the present invention comprises:

[0052] 1. Weigh a certain amount of whey protein isolate, add distilled water at a solid-to-liquid ratio of 1:15, and mix well.

[0053] 2. Preparation of hydrolyzate: adjust the pH of the above-mentioned whey protein isolate solution to 7.0, add trypsin with a mass ratio of enzyme to substrate of 0.8% (w / w) therein, and perform hydrolysis at 60° C. for 120 min. The solution was treated with boiling water to inactivate enzymes for 15 minutes, and then spray-dried to obtain whey protein isolate hydrolyzate. The spray drying conditions are: air inlet temperature 185°C, air outlet temperature 80-90°C, flow rate 20mL / min.

[0054] 3. Weigh a certain amount of whey protein isolate hydrolyzate, add distilled water at a solid-to-liquid ratio of 1:15, and mix well.

[0055] 4. Preparation of cross-linked product: adjust the pH of the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com