Preparation method for transglutaminase liquid enzyme activity stable preparation

A technology for glutamine and stabilizing preparations is applied in the field of preparation of glutamine transaminase liquid enzyme activity stabilizing preparations, and achieves the effects of easy availability, reduced production cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

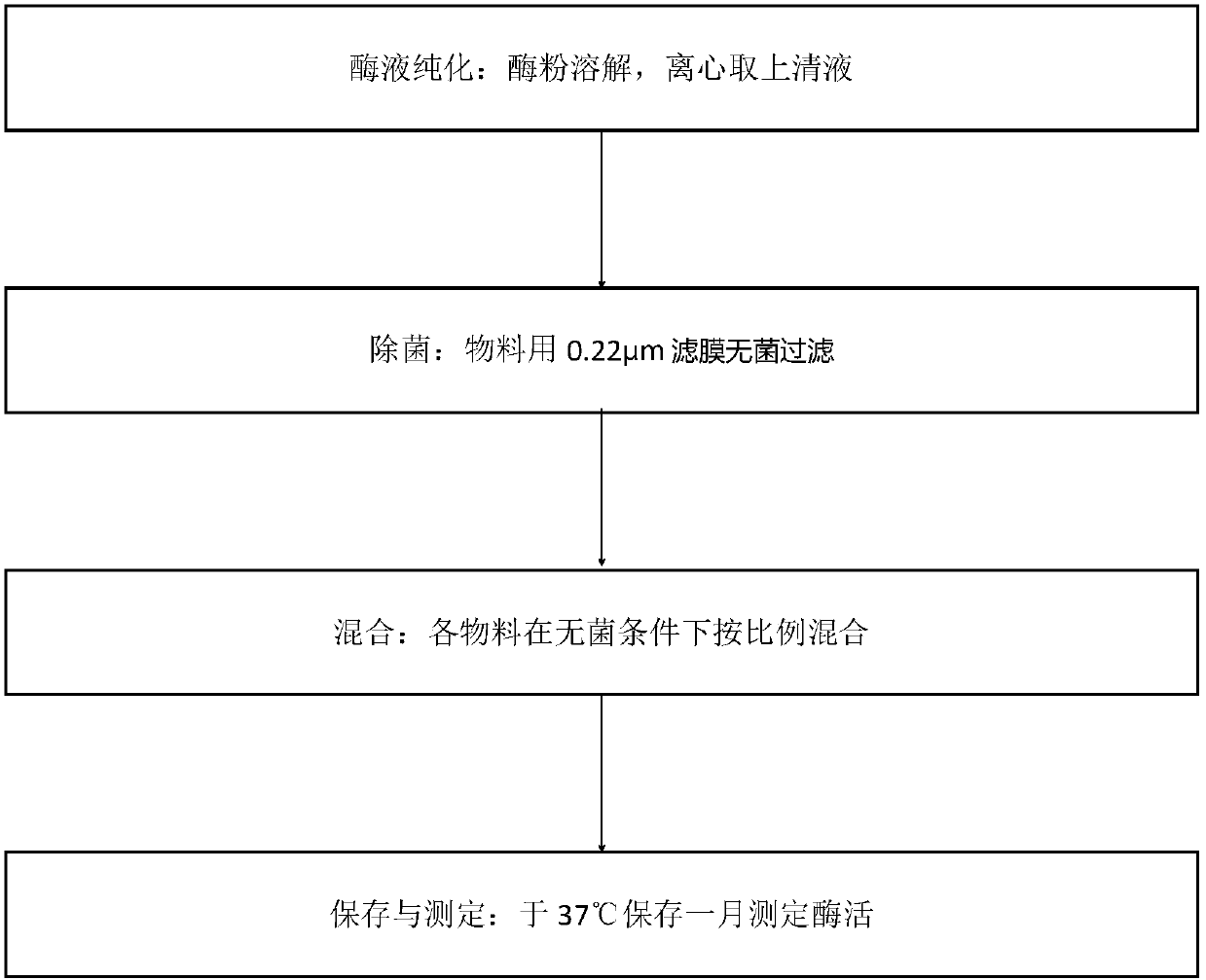

[0027] The preparation method of the stable preparation of transglutaminase liquid enzyme activity proposed by the present invention comprises steps:

[0028] 1) Enzyme powder dissolution: mix transglutaminase enzyme powder with water, dissolve and centrifuge, and take the supernatant;

[0029] 2) Sterilization: use 0.22μm membrane filter to sterilize the enzyme solution and reagents;

[0030] 3) Mixing: Quantitatively measure or weigh the enzyme solution, water activity regulator, and redox potential agent obtained in step 2), mix, make up 100% volume with a pH regulator, and mix evenly; obtain the glutamine Enzymatic stable preparation of amide transaminase liquid enzyme.

[0031] It further includes step 4) placing in a constant temperature environment at 37°C. For example, place it in a constant temperature environment at 37°C for one month, and measure the final enzyme activity. Such as figure 1 shown.

[0032] In order to achieve the above object, the present invent...

Embodiment 1

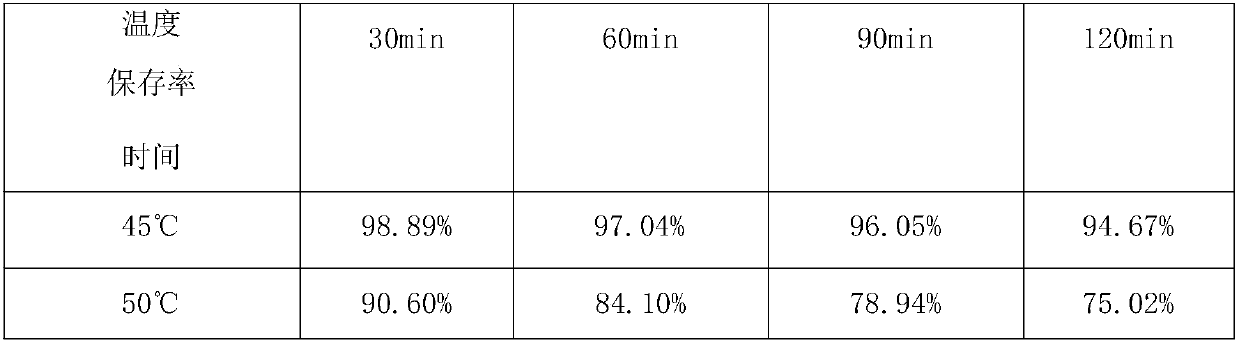

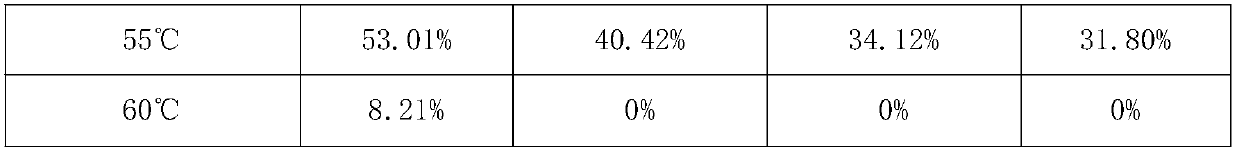

[0035] Inactivation situation under different temperatures under the pure enzyme liquid of embodiment 1

[0036] The pure enzyme solution with a concentration of 100U / mL was treated in a water bath at different temperatures for different times, and the enzyme activity was measured. The specific results are shown in Table 1.

[0037] Table 1. Changes in enzyme activity at different temperatures and at different times

[0038]

[0039]

[0040] The data in Table 1 show that under the same treatment time, transglutaminase loses less enzyme activity at 45°C, almost no enzyme activity after treatment at 60°C for 30 minutes, and the rate of enzyme activity inactivation is the fastest at 55°C for 30 minutes. Therefore, 55°C, 30min is selected as the temperature and time of the heat treatment experiment after comprehensive consideration.

Embodiment 2

[0041] The influence on the thermal stability of liquid enzyme under the different water activity modifiers of embodiment 2

[0042]Different single water activity regulators were mixed with 100U / mL pure enzyme solution at a ratio of 1:1, and treated in a 55°C water bath for 30 minutes. After the treatment, the enzyme activity was quickly measured in an ice water bath.

[0043] Table 2. Examples of enzyme activity stability under different carbohydrate treatments

[0044]

[0045] The data in Table 2 show that the addition of sugars in the water activity agent can prolong the stability of transglutaminase at high temperatures, and glucose, trehalose, and sucrose have a greater impact on the preservation rate of enzyme activity. % as an example, the enzyme activity preservation rate under 55 ℃ 30min treatment is above 74%. Therefore, glucose, trehalose, and sucrose are preferably selected as water activity regulators for prolonging the long-term storage of enzyme liquid.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com