Immobilized glutamine transaminase preparation method

A technology of glutamine and transaminase, applied in biochemical equipment and methods, acyltransferase, transferase and other directions, can solve problems such as easy loss of enzyme activity, and achieve the effects of low price, improved stability and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Weigh a certain amount of transglutaminase proenzyme, add an appropriate amount of pure water to dissolve, and prepare an enzyme solution with an enzyme activity of 600U / mL, the measured pH=6.26, and the water activity is 0.97, and then sterilized for later use.

[0039] 2) Prepare natural high molecular compounds such as dextran gel into a suspension, heat and melt to sterilize.

[0040] 3) Cool the sterilized carrier suspension to room temperature, mix it with 100 U / mL free glutamyl transaminase in a certain proportion, and place it in a refrigerator at 4°C for 30 minutes.

[0041] 4) Wash twice with deionized water, add 1% glutaraldehyde solution to enhance immobilization and cross-linking for 1 hour, remove glutaraldehyde, and wash twice with deionized water.

[0042] 5) Add the corresponding formula to the immobilization system according to the following table 2 to prepare immobilized transglutaminase.

[0043] Table 2 Immobilized transglutaminase formula

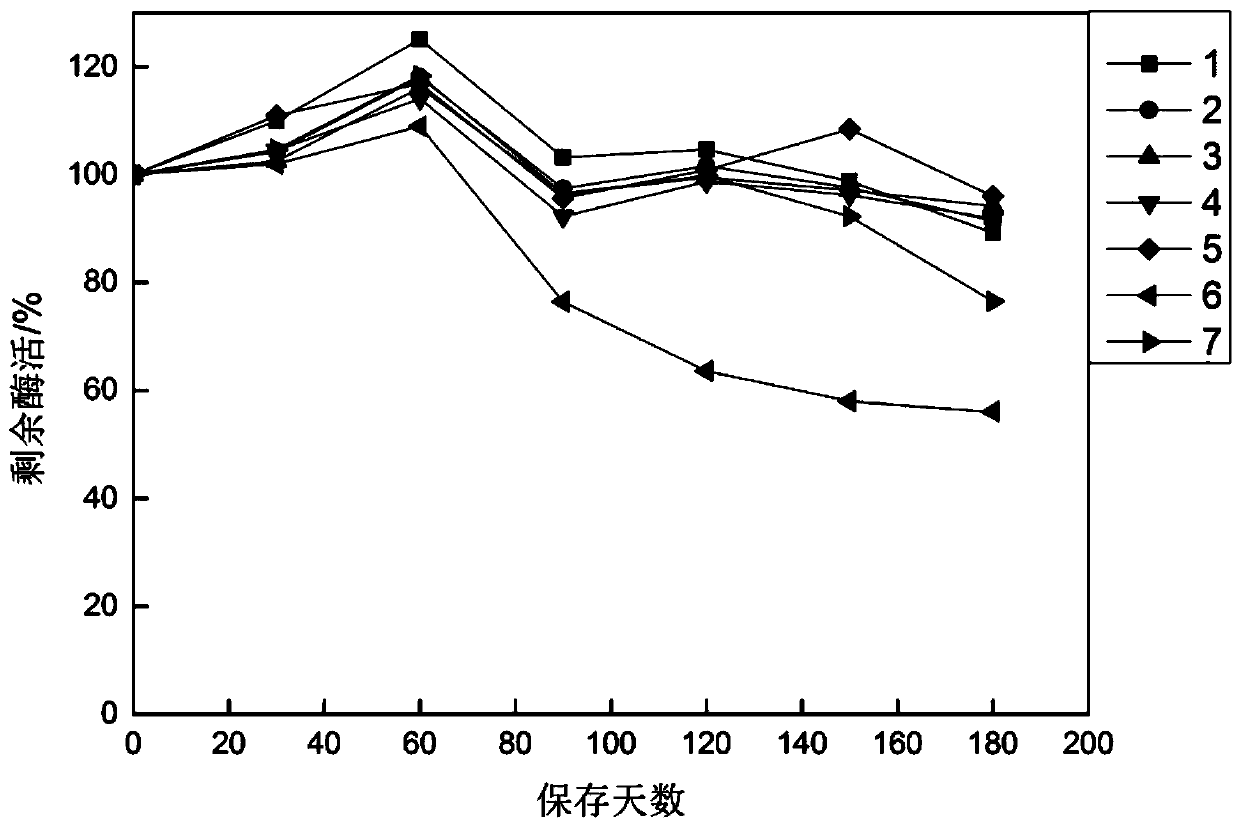

[0...

Embodiment 2

[0047] 1) Weigh a certain amount of transglutaminase proenzyme, add an appropriate amount of pure water to dissolve, and prepare an enzyme solution with an enzyme activity of 600U / mL, the measured pH=6.26, and the water activity is 0.97, and then sterilized for later use.

[0048] 2) Prepare natural high molecular compounds such as agarose gel into a suspension, heat and melt to sterilize.

[0049] 3) Cool the sterilized carrier suspension to room temperature, mix it with 100 U / mL free glutamyl transaminase in a certain proportion, and place it in a refrigerator at 4°C for 30 minutes.

[0050] 4) Wash twice with deionized water, add 1% glutaraldehyde solution to enhance immobilization and cross-linking for 1 hour, remove glutaraldehyde, and wash twice with deionized water.

[0051] 5) Add the corresponding formula to the immobilization system according to Table 3 to prepare immobilized transglutaminase.

[0052] Table 3 Immobilized transglutaminase formula

[0053]

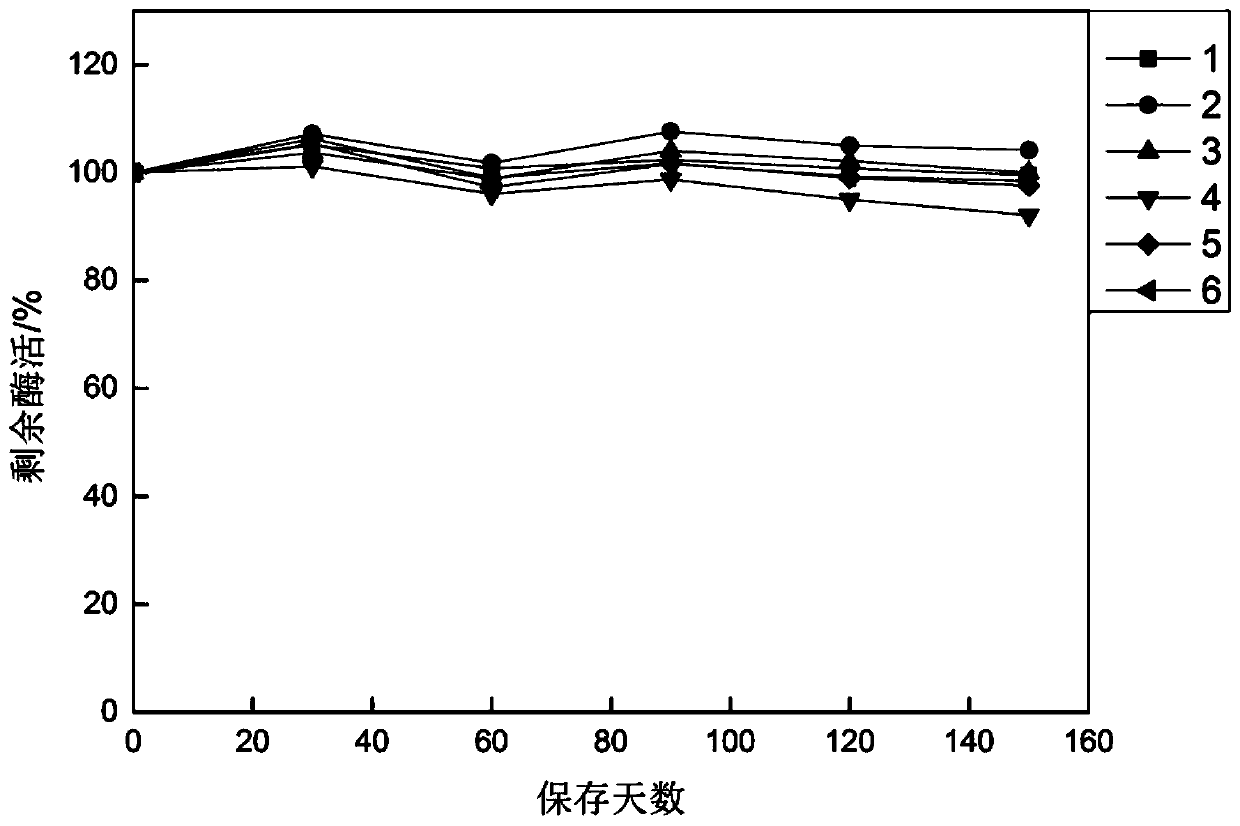

[005...

Embodiment 3

[0056] 1) Weigh a certain amount of transglutaminase proenzyme, add an appropriate amount of pure water to dissolve, and prepare an enzyme solution with an enzyme activity of 600U / mL, the measured pH=6.26, and the water activity is 0.97, and then sterilized for later use.

[0057] 2) Prepare natural high molecular compounds such as agarose gel into a suspension, heat and melt to sterilize.

[0058] 3) Cool the sterilized carrier suspension to room temperature, mix it with 100 U / mL free glutamyl transaminase in a certain proportion, and place it in a refrigerator at 4°C for 30 minutes.

[0059] 4) Wash twice with deionized water, add 1% glutaraldehyde solution to enhance immobilization and cross-linking for 1 hour, remove glutaraldehyde, and wash twice with deionized water.

[0060] 5) Add the corresponding formula to the immobilization system according to Table 4 to prepare immobilized transglutaminase.

[0061] Table 4 immobilized transglutaminase formula

[0062]

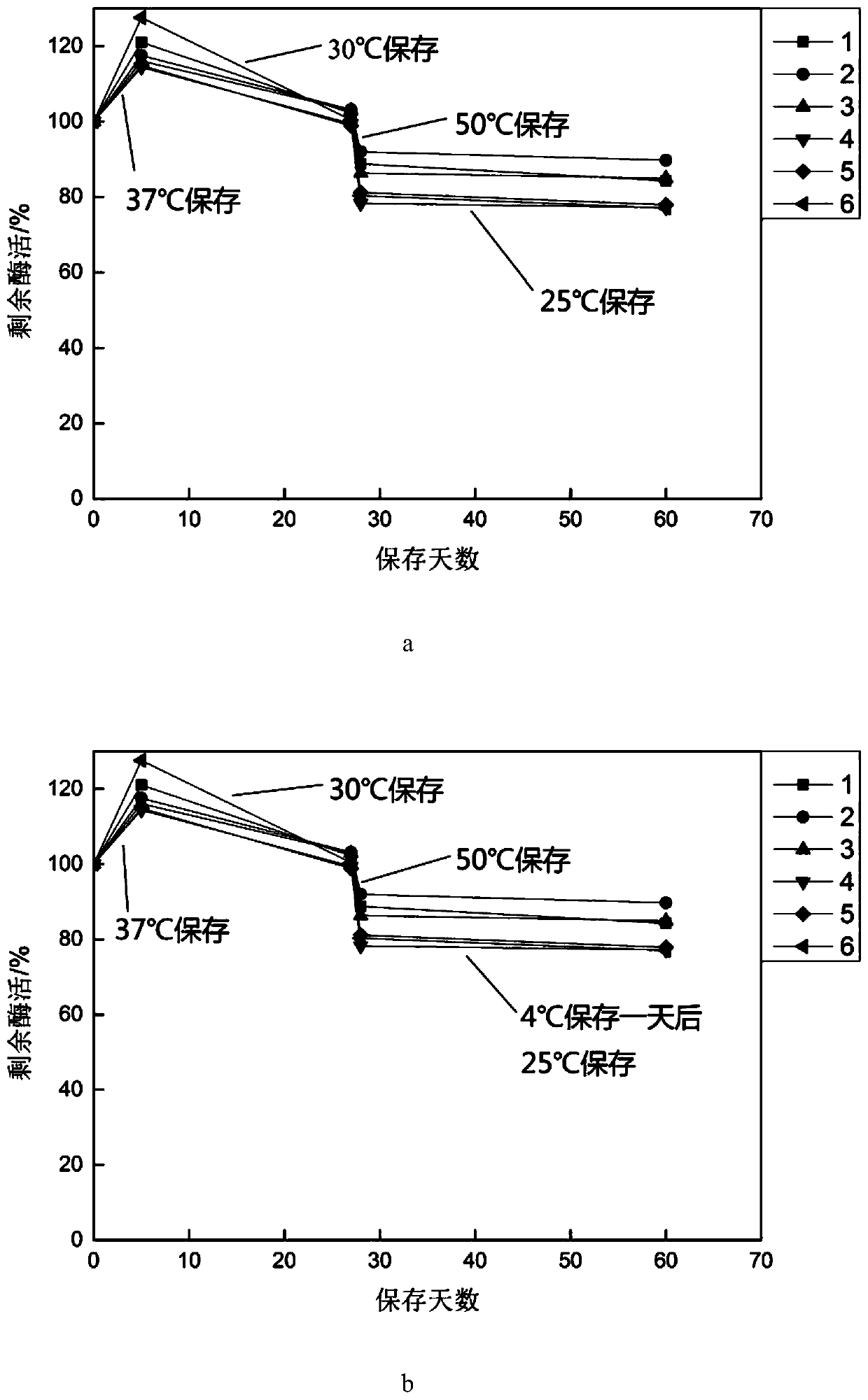

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com