Glutamine transaminase production bacterium

A technology of glutamine and transaminase is applied in the field of glutamine transaminase production bacteria, and can solve the problems of low fermentation level of production strains and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

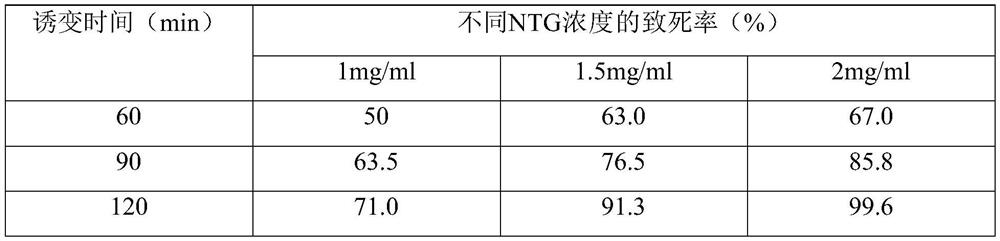

[0039] Example 1: Mutagenesis and screening of strain DSHO0618 nitrosoguanidine

[0040] Nitrosoguanidine (NTG) is a strong carcinogenic mutagenic substance. In order to prevent harm to the human body, rubber gloves, work clothes, and a mask should be worn during operation. After the mutagenesis is completed, anyone who has been in contact with nitrosoguanidine The utensils must be disposed of in time, soak the consumables in 1M sodium hydroxide solution (8g sodium hydroxide dissolved in 200mL distilled water) overnight, and use 0.5% sodium thiosulfate (7.9g sodium thiosulfate dissolved in 100mL distilled water) water) to wipe down the cabinet.

[0041] 1.1 Activation of strain DSHO0618 and preparation of spore suspension: Streak a line from the glycerol tube of strain DSHO0618 onto Gaoshi No. 1 plate, and culture at 30°C for about 7 days.

[0042] Add 10ml of phosphate buffer solution (pH6.0) to the culture plate (petri dish), gently scrape the bacteria with a sterile toothp...

Embodiment 2

[0053] Embodiment 2: Fermentation and Yield Determination of Transglutaminase-producing Strains

[0054] 2.1 Strain shake flask fermentation

[0055] Seed culture: After the fermentation medium is prepared and mixed, it is divided into 50ml / bottles into 250ml shake flasks, and a quarter of the spores on the culture plate obtained in Example 1.4 are scraped with an inoculation loop and inoculated in shake flasks. C, 220rpm and cultivate for 24h to obtain the seed culture solution.

[0056] Shake flask fermentation: Prepare and mix the fermentation medium and distribute 30ml / bottle into a 250ml shake flask, inoculate 3ml of seed culture solution into the fermentation shake flask, and culture at 30°C and 220rpm for about 28h. The fermentation broth was centrifuged at high speed, and the supernatant was taken to detect the enzyme activity.

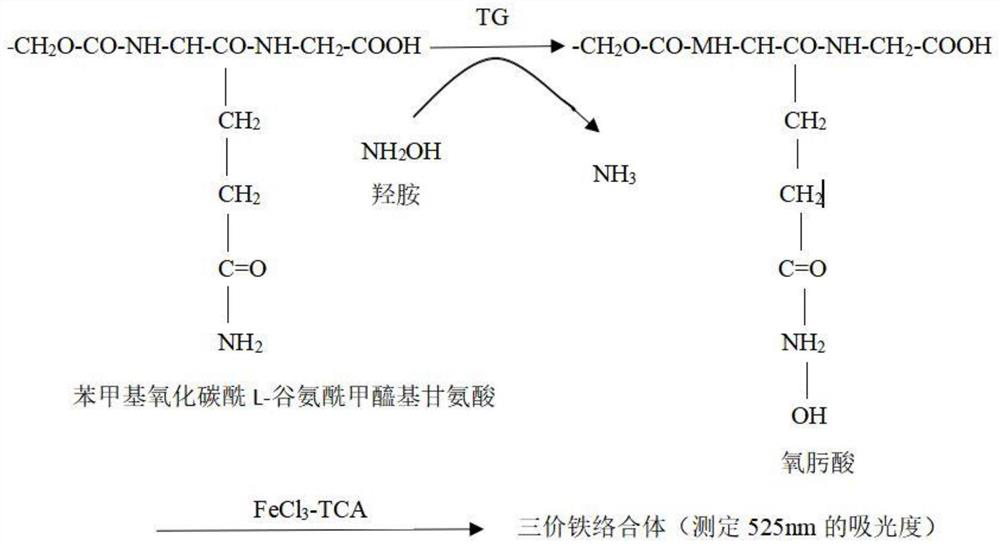

[0057] 2.2 Determination of enzyme activity of transglutaminase

[0058] 2.2.1 Principle

[0059] The principle of the enzyme activity as...

Embodiment 3

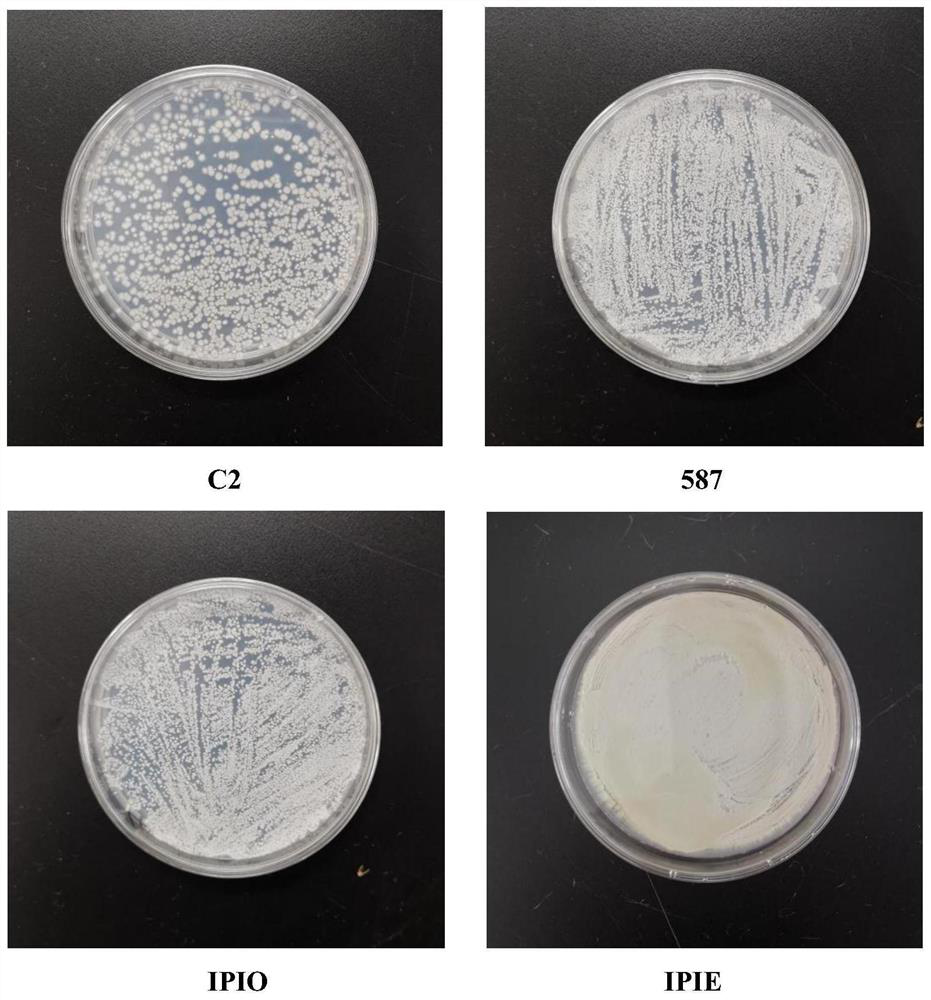

[0074] Embodiment 3: Ultraviolet mutagenesis of mutant strain C2

[0075] 3.1 Preparation of spore suspension: add 5ml of sterile water to the strain C2 culture plate (petri dish), gently scrape the bacteria with a sterile toothpick, blow and mix 5 times with a 1ml pipette, and then put it into a 100ml sterile Erlenmeyer flask Medium (with 2g of glass beads), seal the bottle with a sealing film, put it in a constant temperature shaker at 200r / 5min to oscillate to break up the bacteria, use a 1ml pipette to draw the bacteria solution, and filter it through a sterile funnel with 0.45μm filter paper. In a new sterile Erlenmeyer flask, draw the filtrate into a sterile 2ml EP tube (2 tubes), centrifuge at 3000g / min for 10min, pipette the supernatant and discard it.

[0076] 3.2 Mutagenesis (the following operations need to be protected from light): add 1ml sterile water to each tube, blow and mix 5 times with a 1ml pipette, then use a 1ml pipette to draw 1ml of the bacterial solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com