Separation and purification method of microbial transglutaminase

A technology for separation and purification of glutamine, which is applied in the field of separation and purification of biotechnology, can solve the problems of complex purification process, low recovery rate and high cost of transglutaminase, and achieve industrial production convenience, low cost and stable properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 alcohol precipitation obtains MTGase crude extract

[0032] (1) Centrifuge 8,000g of the fermented broth at 4°C for 10 minutes to remove the precipitate; slowly adjust the pH to 5.0 with phosphoric acid, and centrifuge at 8,000g for 10 minutes at 4°C to remove the precipitate; Add, place in an ice box for 1 hour, centrifuge at 8000g for 10 minutes at 4°C, and remove the supernatant.

[0033] (2) SDS-PAGE detection results such as Figure 4 As shown in middle lane 2, the molecular weight of MTGase is about 38KDa. From lane 2, it can be seen that the crude extract obtained by alcohol precipitation contains a large amount of miscellaneous proteins. The total enzyme activity of the fermentation broth before alcohol precipitation was 2760.6U, and the total enzyme activity after alcohol precipitation was 2484.5U. The specific results are shown in Table 1. The enzyme activity assay results showed that the total enzyme activity recovery rate in this step was 90%....

Embodiment 2

[0034] The detection of embodiment 2MTGase crude extract temperature stability

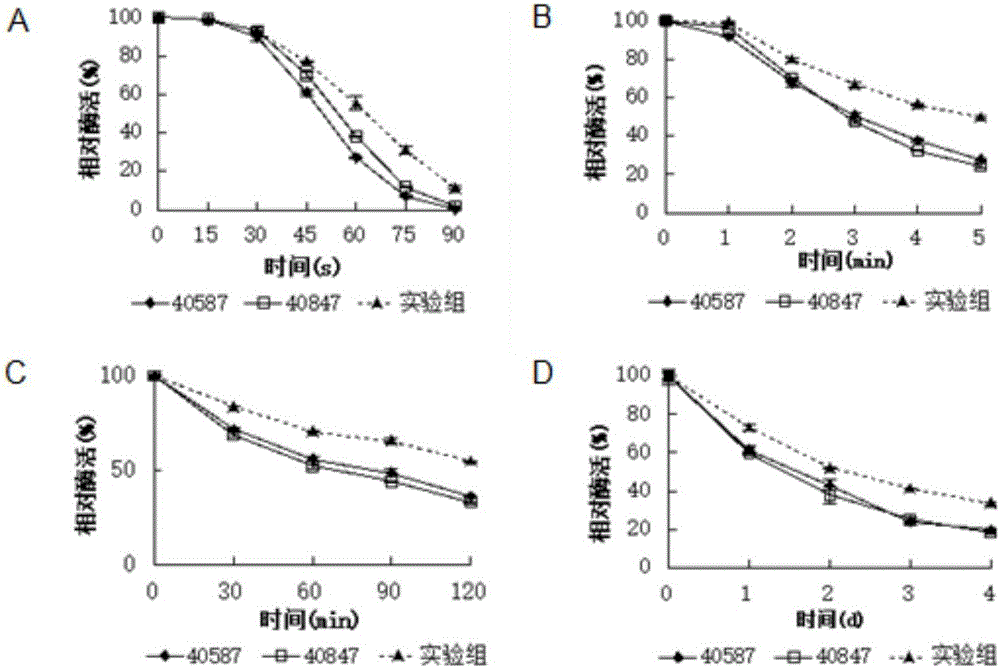

[0035] (1) The MTGase (experimental group) obtained by alcohol precipitation in Example 1 is lyophilized and dissolved in the phosphate buffer of pH6.0 with 3U / mL, and two arbitrary two MTGases (control group) that have been reported at present are selected simultaneously. 1: 40587 and the control group 2: 40847 (both from Taixing Dongsheng Food Technology Co., Ltd.) were used as controls, and were also dissolved in phosphate buffer at pH 6.0 at 3 U / mL.

[0036] (2) Place the three MTGases in water baths at 40°C, 50°C, 60°C and 70°C respectively, and press figure 2 Store MTGase at intervals under various temperature conditions shown, and measure the enzymatic activity of MTGase after a certain period of time. A is the result of different MTGase stability at 70°C, B is the result of different MTGase stability at 60°C, C is the result of different MTGase stability at 50°C, D is the result of differ...

Embodiment 3

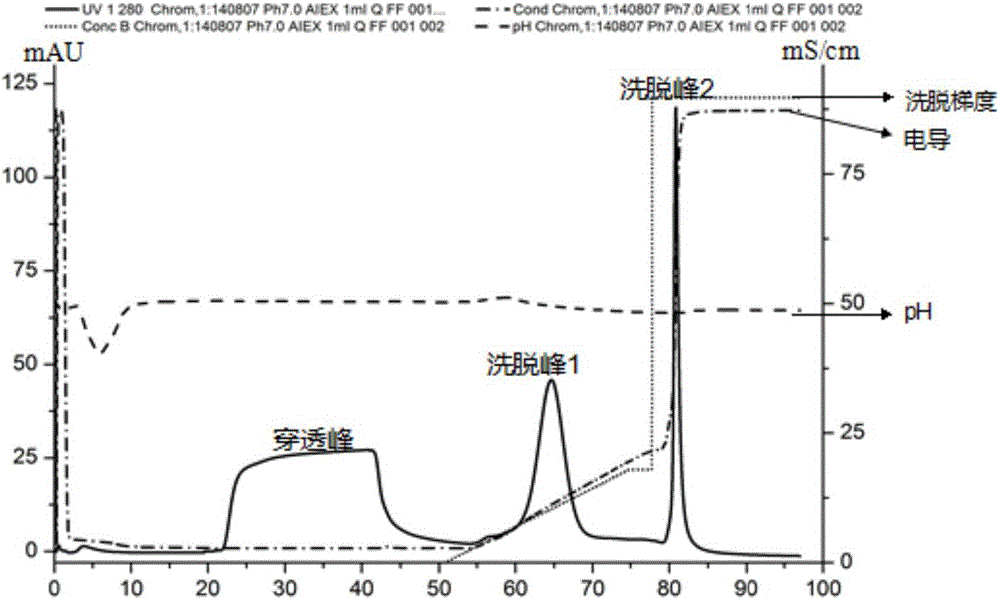

[0038] Example 3 Anion-exchange chromatography method obtains high-purity MTGase after purification

[0039] (1) The purification instrument selected is from General Corporation of the United States avant25, the chromatographic column used for purification is a prepacked anion exchange column HiprapQSepharose FF (1 mL) purchased from General Corporation of the United States.

[0040] (2) Appropriate amounts of 20 mM sodium dihydrogen phosphate and 20 mM disodium hydrogen phosphate were prepared respectively, and the two buffer solutions were mixed in proportion to finally prepare a phosphate buffer solution with a pH of 6.5, and the conductance was about 2.5 mS / cm. After preparation, use a 0.22um filter membrane to filter, and then degas in an ultrasonic instrument for 20-30min. Store in refrigerator at 4°C for later use.

[0041] (3) Add 1M sodium chloride on the basis of the equilibrium buffer, and after fully dissolving, adjust the pH to 6.5 with phosphoric acid, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com