Water-resistant bio-based formaldehyde-free adhesive for wood and preparation method thereof

An aldehyde adhesive, bio-based technology, applied in the field of aldehyde-free adhesive preparation, can solve the problems of unfavorable industrialization of soybean protein adhesives, high cost of soybean protein adhesives, high solid content, etc. The effect of reducing the amount, reducing the processing energy consumption and increasing the solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

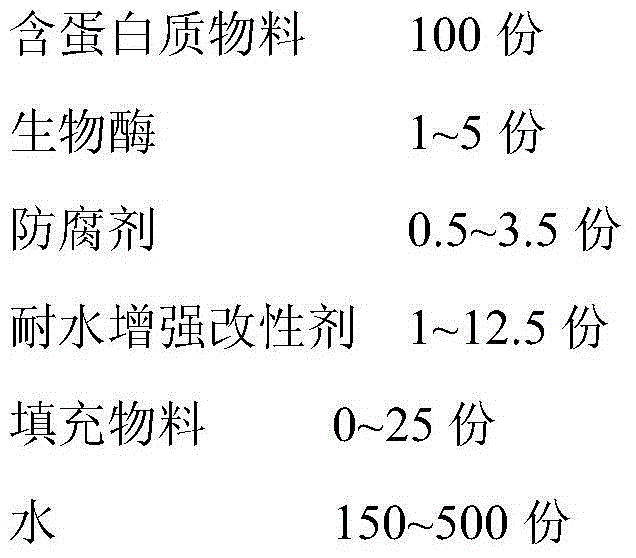

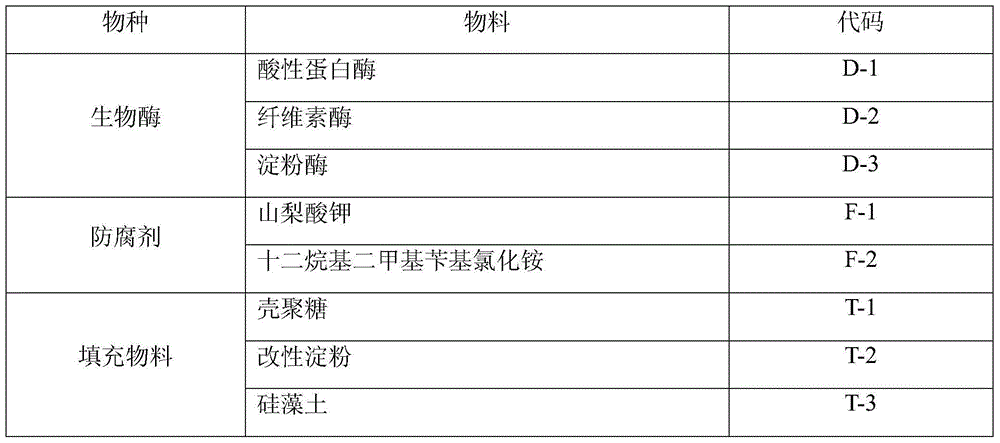

Method used

Image

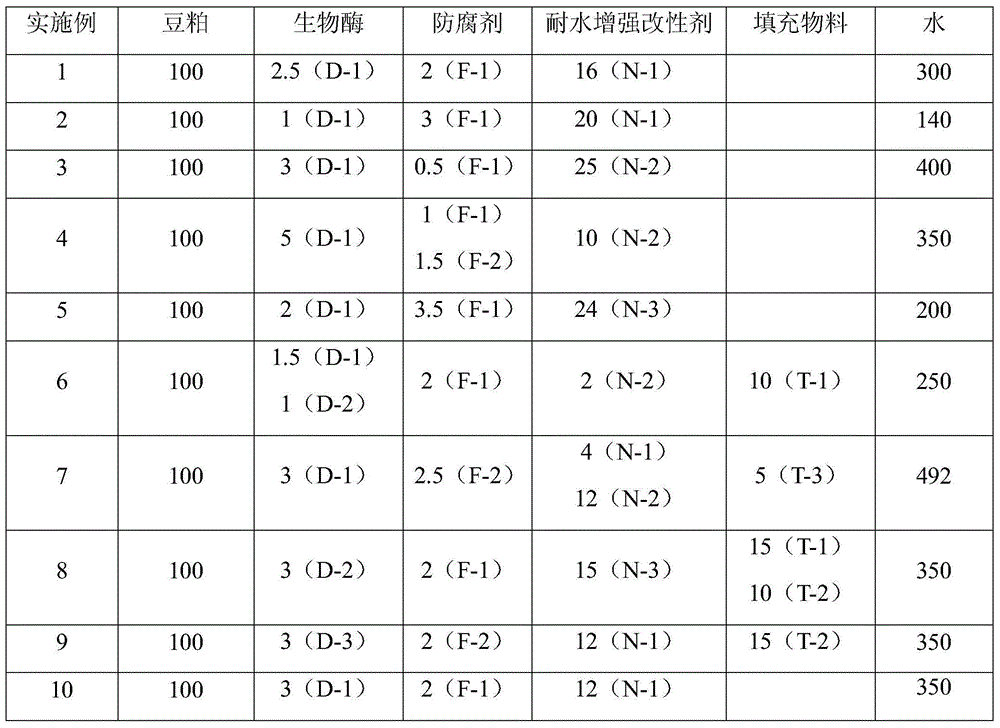

Examples

Synthetic example 1

[0034] Synthesis example 1 (polycondensation product of polyol and dialdehyde)

[0035] 80 parts by mass of water, 30 parts by mass of sorbitol, and 50 parts by mass of glutaraldehyde were added to the reaction flask, the temperature was raised to 70°C, and the temperature was kept for 3 hours to obtain a mixture of polyol and dialdehyde with an active ingredient content of 50%. Aqueous polycondensate solution, labeled N-1.

Synthetic example 2

[0036] Synthesis example 2 (polyamide uret epoxy adduct)

[0037] Add 5 parts by mass of water, 50 parts by mass of spermidine, and 40 parts by mass of adipic acid into the reaction flask, raise the temperature to 160°C for 30 minutes, then slowly raise the temperature to 190°C, and continue the reaction for 2 hours under vacuum. After the vacuum was broken, the temperature was lowered to 100° C., 10 parts by mass of urea was added, and the temperature was raised to 130° C. for 1.5 h. After lowering the temperature to 100°C again, 100 parts by mass of water was added to obtain an aqueous solution of polyamide urea. At 35°C, add 25 parts by mass of epichlorohydrin, slowly raise the temperature to 60°C, and react for 3 hours to obtain an aqueous solution of polyamide uret epoxy adduct with an active ingredient content of 50%, marked as N-2.

Synthetic example 3

[0038] Synthesis example 3 (polyamide uret epoxy adduct)

[0039] Only spermidine is replaced by spermidine mixture, epichlorohydrin is replaced by ethylene glycol diglycidyl ether, the rest is the same as in Synthesis Example 2, and the obtained aqueous solution of polyamide uret epoxy adduct with an active ingredient content of 50% , labeled N-3.

[0040] The commercially available active ingredient is 30% KR-005 ammonium zirconium carbonate (Lishui City Kairun Chemical Co., Ltd.), marked as N-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com