Degradable film containing starch and preparation method of degradable film

A technology for degrading film and starch, which is applied in the field of polymer materials, can solve the problems of poor water resistance, difficult processing, poor mechanical properties, etc., and achieve the effect of excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

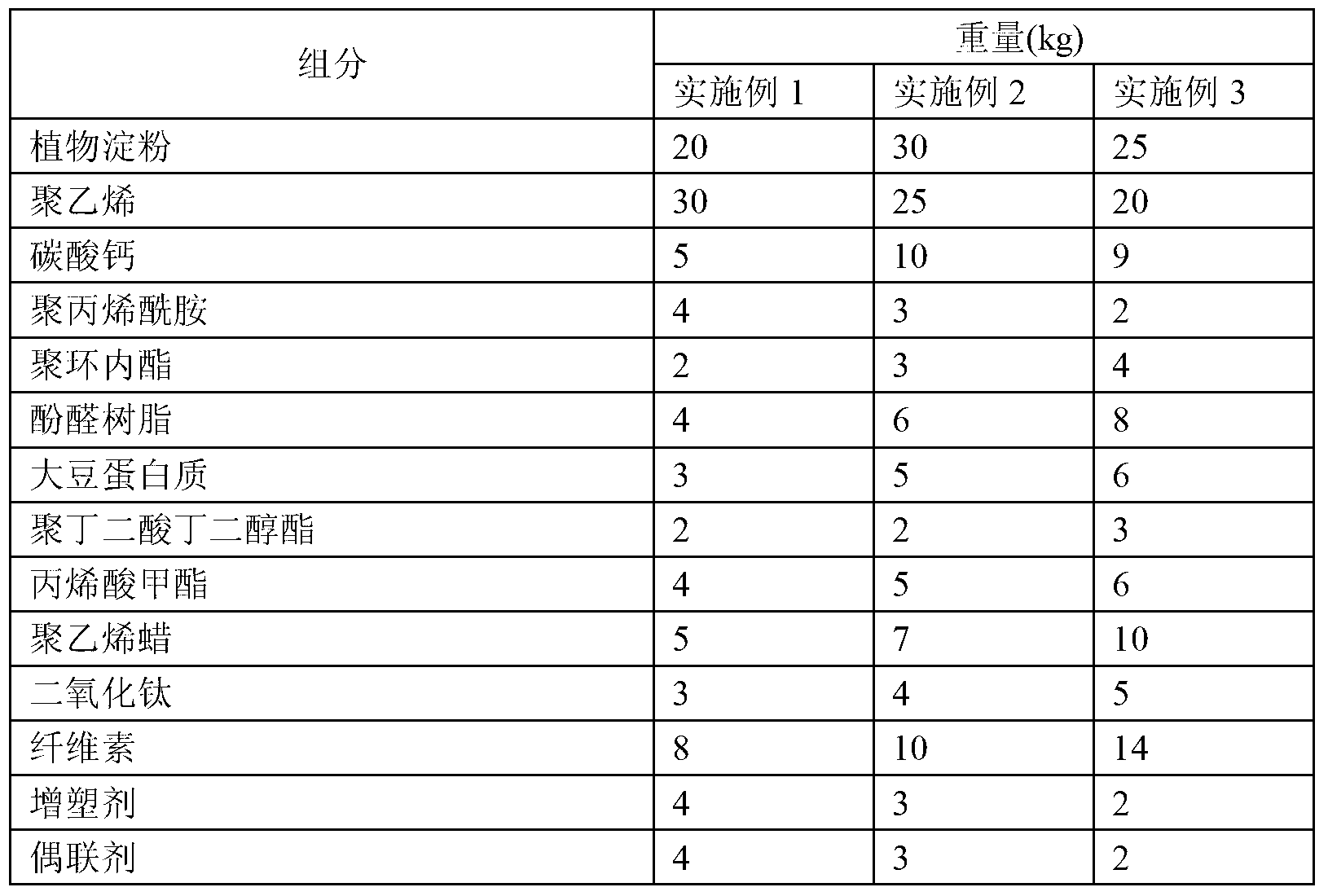

[0018] The weight proportion of table 1 embodiment 1~embodiment 3

[0019]

[0020] In the foregoing embodiment, cornstarch is used for vegetable starch; carboxymethyl cellulose is used for cellulose; ethylene glycol is used for plasticizer; the particle size of titanium dioxide is 10 to 50 microns; 550.

[0021] The preparation steps are:

[0022] S1: Mix vegetable starch, polyethylene, polyacrylamide, polycyclic lactone, phenolic resin, soybean protein, polybutylene succinate, methyl acrylate, polyethylene wax, plasticizer, and coupling agent evenly ;

[0023] S2: Put the mixture obtained in step S1 into the hopper of the twin-screw extruder, then put calcium carbonate, titanium dioxide, and cellulose into the side feeding hopper of the extruder, and perform melting, mixing, extrusion, cooling, and drying , Diced into pellets, and you get it. The screw temperature of the twin-screw extruder is controlled between 190-210° C., and the screw speed is controlled at 140-16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com