Hydrophilicity polyethylene hollow fiber micro-hole film and the preparation method

A polyethylene and hydrophilic technology, which is applied in the field of membrane separation, can solve the problems of preparing hydrophilic polyethylene hollow fiber microporous membranes by the TIPS method, and achieve outstanding pollution resistance, outstanding hydrophilic effect, and precise interception performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

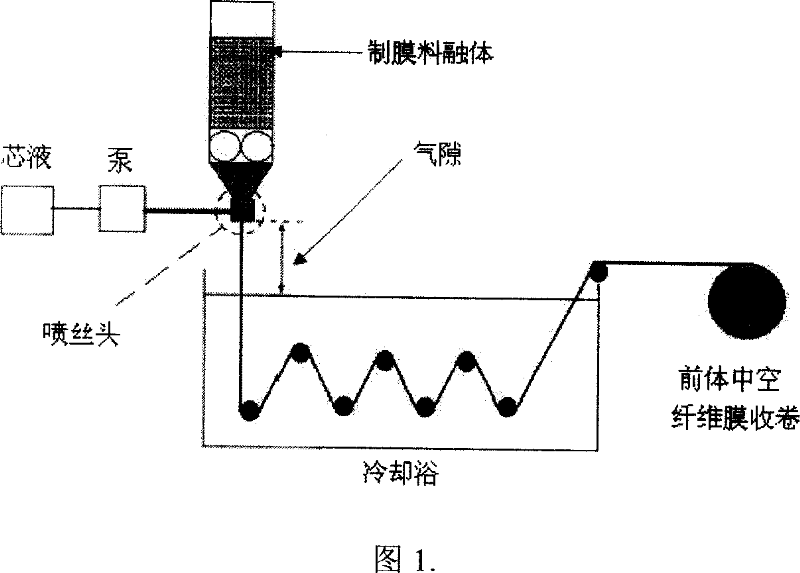

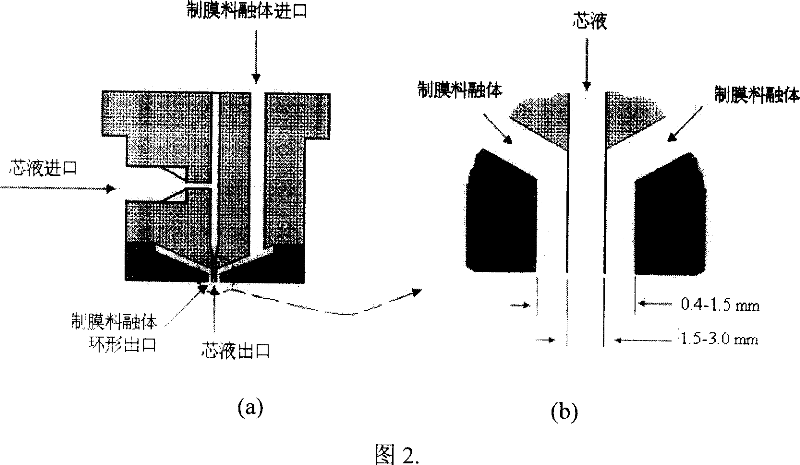

[0030] The preparation process of the membrane in the invention consists of three steps: preparation of membrane material, molding of precursor hollow fiber membrane and extraction to form pores. The preparation of the membrane-making material is to mix polyethylene, polyethylene oxide-containing amphiphilic copolymer, inorganic nanoparticles and diluents, and then melt and blend them into a uniform membrane-making material; the molding of the hollow fiber membrane is: the molten state The membrane material is solidified into a precursor hollow fiber membrane through a hollow fiber molding process with water or a diluent as a cooling bath (see Figure 1); the extraction to form pores is to extract the diluent in the precursor hollow fiber membrane with an organic solvent, and the The dense structured precursor hollow fiber membranes are converted into hollow fiber microporous membranes. The three steps can be continuous or intermittent.

[0031] The molecular weight range of t...

Embodiment 1

[0047] (1) Preparation of film-making material: high-density polyethylene polyethylene (molecular weight 1.0×10 5 ), poly(ethylene-ethylene oxide) (molecular weight is 5.0×10 2 , PEO content is 20%), silica nanoparticles (50 nanometers) and diphenyl ether are melted and blended into a uniform film-making material at 170 ° C in the melting material kettle at a ratio of 30: 10: 0.5: 60, and the time is 2 hours. Then stand at 170°C for 1 hour for degassing;

[0048] (2) Forming of hollow fiber membrane: with diphenyl ether at 30°C as the core liquid, extrude the melt of the film-making material at 0.2 MPa through a spinneret at 140°C to form a tubular liquid film, and the liquid film passes through a 10 cm long Enter the water cooling bath at 20°C after entering the air gap to solidify into a precursor hollow fiber membrane;

[0049] (3) Extraction to form pores: soak the precursor hollow fiber membrane in ethanol extractant at 20° C. for 24 hours, take it out and dry it in th...

Embodiment 2

[0053] The preparation steps are the same as in Example 1, and the various implementation conditions and the structure and performance of the obtained hydrophilic polyethylene hollow fiber microporous membrane are shown in Table 2.

[0054] Cast film material

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com