Curable elastomer impression material

A body printing and elastic technology, applied in the fields of compression molding cups, dental prosthesis, medical science, etc., can solve the problems of air and environmental pollution, cumbersome, complicated recycling process, etc., achieve stable hydrophilic performance, simple surface treatment process, Good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

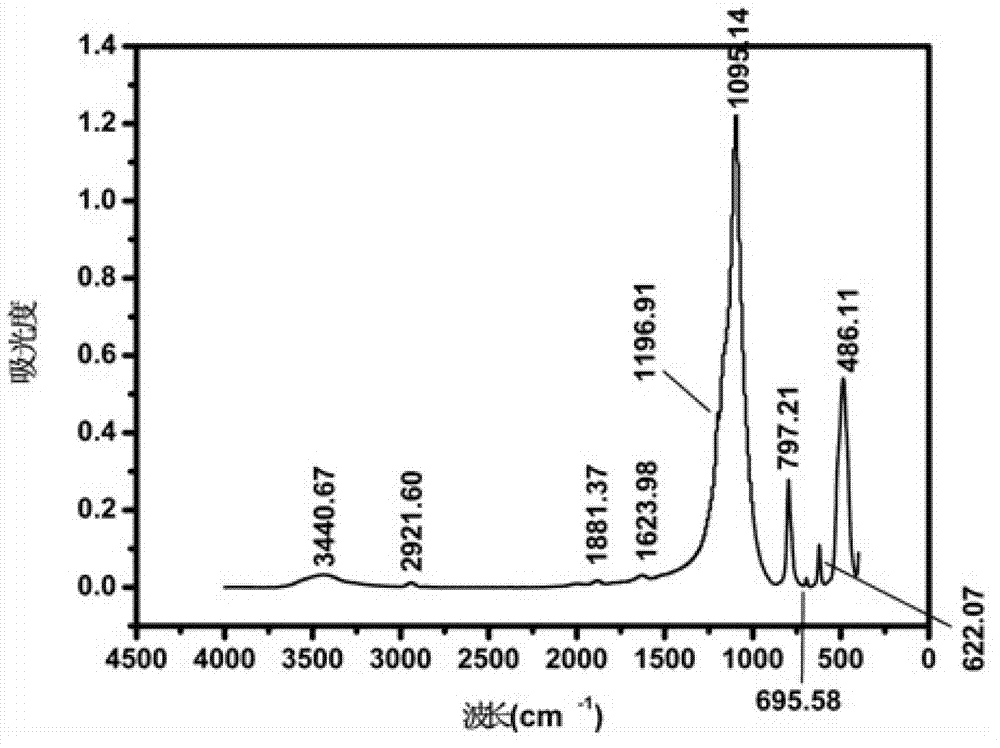

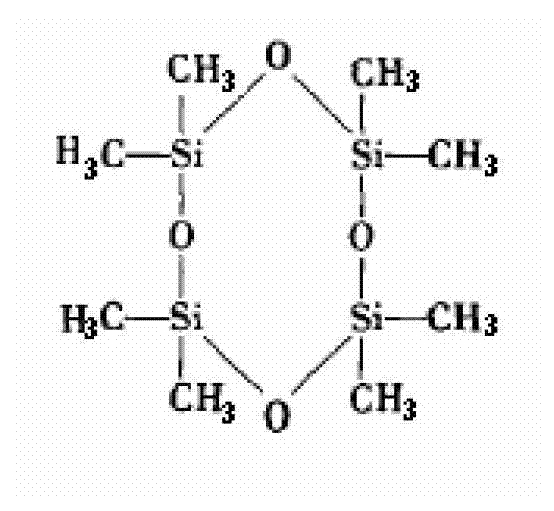

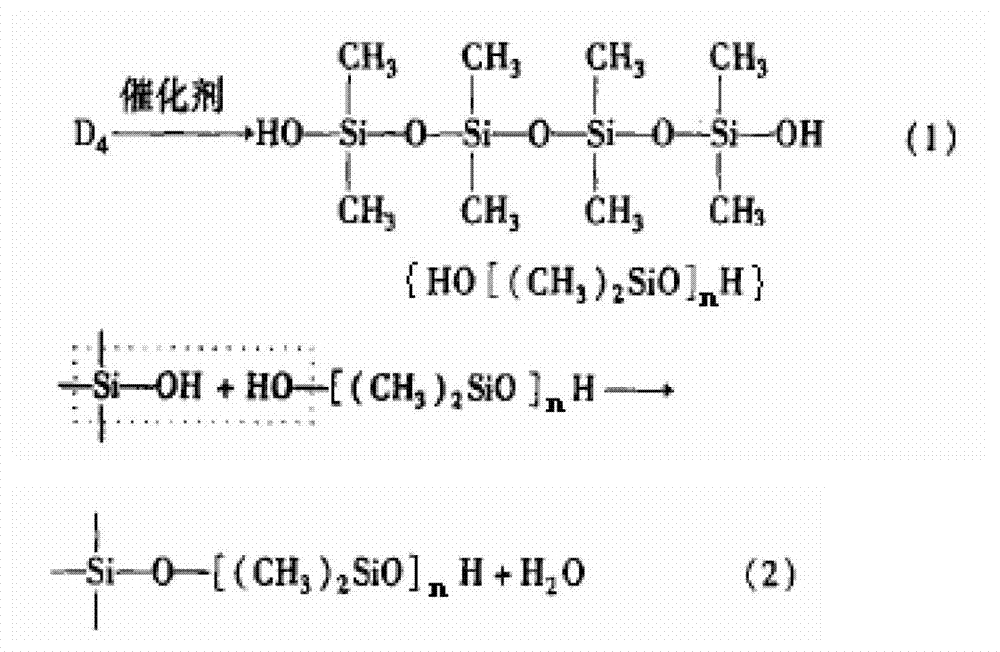

[0057] Weigh 1000g of quartz powder (particle size 1-10μm) and dissolve it in 2000g ethanol solution (ethanol concentration is 50wt%), add 10g dispersant span80, 75g acid catalyst acetic acid and specified weight of silane coupling agent D4 (specifically The dosage is shown in Table 1), after dispersing evenly, heat to 70°C and stir for 2 hours, then dilute with water to a pH value between 5-6, and directly spray dry to obtain a hydrophobic cristobalite product, no by-products are formed in the whole reaction, Can be used as the filler of the present invention, the degree of hydrophobicity of the filler obtained in each embodiment is shown in Table 1. The infrared absorption spectrum figure of the filler that its embodiment 1 makes is as figure 1 As shown, of which 1095.14cm -1 、797.21cm -1 and 486.11cm -1 The peak at proves that the treated silica structure has not changed; 1196.61cm -1 The peak proves the existence of the skeleton structure Si-O-Si in the powder after tr...

Embodiment 6

[0068] Prepare base paste and catalyst paste according to the formula in Table 2.

[0069] The formula of the basic paste of table 2 embodiment 6 and catalyst paste

[0070]

[0071] Preparation of the impression material: The base paste and the catalyst paste mentioned above were mixed in a volume ratio of 1:1 using a static mixer, and the properties of the obtained impression material are shown in Table 3.

[0072] The performance of the impression material that table 3 embodiment 6 makes

[0073]

Embodiment 7-11

[0075] Prepare base paste and catalyst paste according to the formula in Table 4.

[0076] The formula of the basic paste of table 4 embodiment 7-11 and catalyst paste

[0077]

[0078] Examples 7-11 used the cristobalite micron-sized filler powder prepared in Examples 1-5 according to the formulations in Table 4 to prepare impression materials. The different degree of hydrophobicity of the powder indicates that the number of functional groups on the grafted powder will be different. The larger the degree of hydrophobicity, the greater the number of functional groups on the grafted body, and the better the binding performance between the powder and the monomer; on the contrary A small degree of hydrophobicity means that the number of functional groups on the graft is small, and the binding performance between the powder and the monomer will be poor. The consistency and tensile strength of impression materials prepared by powders with different degrees of hydrophobicity are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com