Preparation method of highly hydrophilic polysulfone ultrafiltration membrane

A technology of polysulfone ultrafiltration membrane and hydrophilicity, which is applied in the direction of chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of poor hydrophilicity of ultrafiltration membranes, achieve excellent hydrophilicity, and improve hydrophilicity , the effect of widely applied value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of a highly hydrophilic polysulfone ultrafiltration membrane of the present invention, the casting membrane liquid system is as follows: the membrane material is selected from polysulfone, the modified material is selected from graphene oxide, the additive is selected from ethylene glycol methyl ether, and the polar organic solvent is selected from N,N-Dimethylformamide.

[0020] The invention discloses a method for preparing a highly hydrophilic polysulfone ultrafiltration membrane. The ratio of components in the casting solution system is as follows: the content of polysulfone is 10%-25%, and the content of graphene oxide is 0.01%- 5%, the content of ethylene glycol methyl ether is 5%-15%, the content of N,N-dimethylformamide is 55%-84.99%, and the content of the above components are all calculated by weight percentage.

[0021] A kind of preparation method of highly hydrophilic polysulfone ultrafiltration membrane of the present invention, its ...

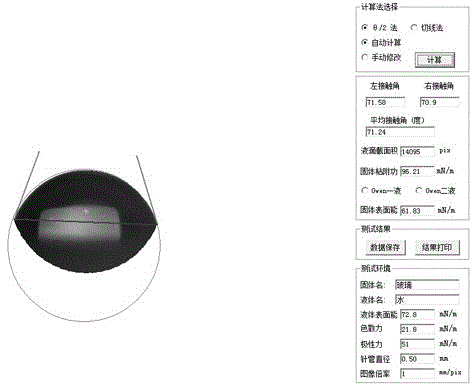

Embodiment 1

[0026] Graphene oxide (selected from Tangshan Jianhua Science and Technology Development Co., Ltd., graphene oxide JH- , the technical index is: the thickness is 0.5-4nm, the lateral dimension is 0.5-3μm, and the number of layers is 1-10 layers) using ultrasonic dispersion in N, N-dimethylformamide, ultrasonic dispersion for 2 hours, forming a uniform and stable dispersion Solution, add ethylene glycol methyl ether to the dispersion solution, stir and mix evenly, slowly add polysulfone to the dispersion solution to form a feed liquid, then raise the temperature of the feed liquid to 80°C, continue to stir and dissolve for 6 hours, and then let it stand for defoaming 16h, a uniform and stable casting solution was formed, and the contents of the components in the casting solution were as follows: graphene oxide 1%, N, N-dimethylformamide 73%, ethylene glycol methyl ether 8%, poly Sulfone 18%.

[0027] Pour the casting solution into the trough of the scraping film equipment. Th...

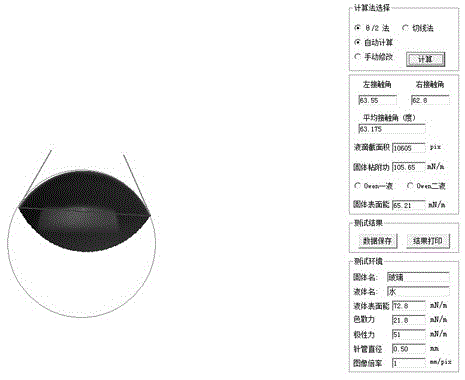

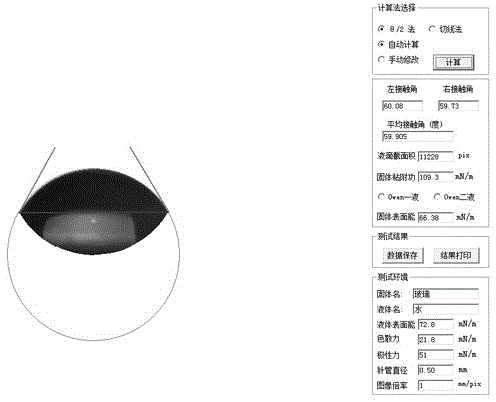

Embodiment 2

[0029] Disperse graphene oxide (same as in Example 1) in N,N-dimethylformamide by ultrasonic wave, and disperse by ultrasonic wave for 2 hours to form a uniform and stable dispersion solution, add ethylene glycol methyl ether to the dispersion solution, stir and mix evenly , slowly add polysulfone to the dispersion solution to form a feed liquid, then raise the temperature of the feed liquid to 80°C, continue stirring and dissolving for 6 hours, and then stand for defoaming for 16 hours to form a uniform and stable casting solution, as described in the casting solution The contents of the components are as follows: 2% graphene oxide, 72% N,N-dimethylformamide, 8% ethylene glycol methyl ether, and 18% polysulfone.

[0030] Pour the casting solution into the trough of the scraping film equipment. The casting solution forms a liquid primary film on the polyester non-woven fabric through a scraper. After passing through a pure water gel bath at 18°C, a phase transformation occurs t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com